Terfenol-D - ETREMA Products, Inc. (original) (raw)

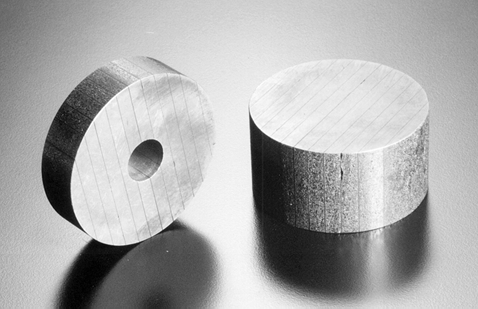

Two laminated pieces of Terfenol-D, one containing a drilled hole.

Terfenol-D is an alloy comprised of Terbium, Dysprosium and Iron. Terfenol-D has the largest room temperature magnetostriction of any known material. Terfenol-D is a solid-state material capable of converting energy from one form to another. In the case of electrical-to-mechanical conversion, the magnetostriction of the Terfenol-D generates strains 100 times greater than traditional magnetostrictives, and 2-5 times greater than traditional piezoceramics. The material has a high Curie temperature (380°C), which enables magnetostrictive performance greater than 1000 ppm from room temperature to 200°C. Adjustments in alloy composition can extend this range down to cryogenic temperatures.

The name Terfenol originated from the metallic elements, Terbium (TER) and Iron (FE); and the discovering organization, Naval Ordnance Laboratory (NOL). Dysprosium (-D) was added as an alloying addition later to reduce the magnetic fields required to induce the magnetostrictive response. NOL, now known as the Naval Surface Warfare Center – Carderock Division (NSWCCD) developed Terfenol-D for high power sonar offering greater bandwidth and reliability over legacy technologies. _Td_Vib holds key patents and licenses for many Terfenol-D applications, including exclusive worldwide licenses to manufacture several types of Terfenol-D materials. _Td_Vib is the world’s leading supplier of Terfenol-D materials and products. Additionally, _Td_Vib provides assistance with the design and manufacturing of Terfenol-D driven products.

Physical Properties

Physical Properties

Terfenol-D’s physical properties are provided in the table. Terfenol-D exhibits a large magnetostrictive and magnetic flux density response versus applied magnetic field over a large range of compressive stresses. The following graphs are representative of Terfenol-D produced by _Td_Vib.

In addition, _Td_Vib can tailor the Terfenol-D composition to allow for a wider operating temperature range. By adjusting the Tb:Dy ratio large magnetostriction values can be achieved at temperatures as low as -200°C and as high as 200°C.

_Td_Vib provides Terfenol-D ready-to-use, lowering the effective cost to our customers. _Td_Vib’s patented crystal growing machines produce solid metallic rods. Customer specific geometries are produced by our unique machining processes. Typical Terfenol-D shapes and sizes are provided below.

Available Terfenol-D Shapes and Sizes

Solid Rods

- Diameters up to 68mm with maximum length of 280mm or less.

- We typically stock rods of diameters 10, 13, 16, 20, 26, 30, 40, 50, 65 and 68mm.

Laminated Rods

- Laminated rods are used for eddy current control in higher frequency applications. _Td_Vib will recommend a lamination thickness based on the operating frequency of your application.

- Minimum lamination thickness available for Terfenol-D is 0.030 inch.

Square Cross-Section

- For smaller sizes and in large quantities, square cross sections are often more cost effective than round cross-sections.

- 2mm square, 3mm square and 4mm square rods are common sizes produced by _Td_Vib.

Holes and Custom Shapes

- Solid and laminated rods are frequently produced with axial holes to facilitate active cooling or prestress application.

- Holes can also be produced in plates and other shapes.

- Non-routine shapes are frequently produced with the axis of maximum magnetostriction in preferred orientations.

Terfenol-D Powder

- Terfenol-D powder is increasingly used for applications such as sensors and composite materials.

- Powder is available in the following various mesh sizes:

| Powder Size (microns) |

|---|

| 0-300 |

| 250-300 |

| 106-300 |

| 106-250 |

| 38-106 |

| 0-38 |

Have questions or want a quotation?

Contact _Td_Vib for a quotation on the quantity and configuration needed. Or work with us to optimize performance and cost for your application