Expanding The Expanding Mandrel's Usefulness (original) (raw)

Users can transfer workpieces through a series of machining and inspection operations without removing them from the mandrel, thus maintaining location and orientation.

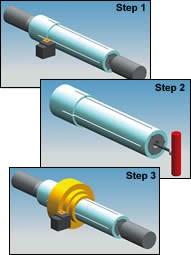

This sequence depicts the three basic steps to preparing and using this expanding mandrel.

Job shops are famously resourceful. To solve difficult machining problems or make work easier, they often invent their own solutions. Then they realize they might have a product to sell to other machine shops. One such shop is Palmer Machine Co., Inc., in Conway, New Hampshire, which owner and founder Michael Palmer started in a basement in 1985. Trained as a design engineer and expert machinist, Mr. Palmer liked to take on the tricky, difficult work other shops avoided. Now located in a 17,000-square-foot facility, his shop has grown to accommodate 20 CNC machines and 42 employees.

Along the way, he found a need to locate and hold thin-walled parts on the ID to avoid distortion during precision machining. He developed a special expanding mandrel with an unusually long length-to-diameter ratio. The mandrel and the part it holds can be moved from machine to machine or to an inspection station. Now, Palmer Machine is producing a line of these mandrels for the national market under the Xpandrel name.

Featured Content

The mandrel expands inside the bore of a workpiece to contact 95 percent of the holding surface. According to the company, this leaves no linear or radial bulges or soft spots, so OD features can be machined without distorting delicate walls. Mr. Palmer notes that the mandrel can also hold heavy workpieces for high machining rates. “We have users machining heavy Inconel valve bodies using our mandrels,” he reports.

The company constructs mandrels that fit IDs smaller than 2.5 inches from solid aluminum. Solid construction allows higher length-to-diameter ratios. For sizes above 2.5 inches, the company uses aluminum tubing to construct the mandrels. On the larger sizes, the end caps can be made of stainless or carbon steel for added support. All sizes can be held between centers, so precise location can be maintained when the mandrel and workpiece are moved from station to station or to inspection. The mandrels can also be held in a chuck or collet with or without a center.

Typically, a customer orders mandrels in a nominal stock size and turns the OD to fit the bore of the workpiece, as shown at left in Step 1. Because the mandrels are made of 6061-T6 aluminum, they are strong but easily machined. After turning, the user loosens the adjuster screws to relax the mandrel body and allow the workpiece to slide on (see Step 2). Tightening the screws expands the body to clamp the workpiece (a force multiplier inside the mandrel creates a grip similar to shrink fit, the company says) and prepares the assembly for machining in a lathe, mill or grinder for machining (see Step 3). While a mandrel can be reused for workpieces with smaller bores by remachining the body to fit, the company says that keeping dedicated mandrels on hand for repeat orders may be more economical because of the product’s pricing.

Custom mandrels can be ordered for specialized applications such as holding IDs greater than 12 inches or lengths greater than 80 inches. These mandrels can accommodate round and non-round shapes or come equipped with a blind end for holding in a collet or chuck. Steel or plastic inserts can be installed on specific locating surfaces, or the entire mandrel can be produced in hardened steel or engineering plastic. Standard or custom mandrels can be used for non-machining applications such as assembly or welding. Holding thin-walled tubing for electron-beam or laser welding is recommended. In addition, the mandrel can be used as an arbor for producing carbon-fiber tubing and other precision fiber- or wire-winding applications.