All You Need to Know About Crash Tests (original) (raw)

Everyone has heard about crash testing, one of the most important parts of testing a new car and making sure it will be safe on the streets, for its driver, its passengers and the other people outside the car, whether we’re talking about pedestrians or other drivers.

Looking in the history books, we find out the world’s first recorded automotive fatality happened on August 31, 1869, when Irish scientist Mary Ward died after falling under the wheels of the experimental steam powered automobile built by her cousins. As for the first recorded motor vehicle fatality, it was Bridget Driscoll, an English teenager that was killed by an automobile as she was crossing the street in Crystal Palace, London. Witnesses described the car as going at a “reckless” speed, even though the car, which was a demo car belonging to the Anglo-French Motor Carriage Company, was only able to go as fast as 8 mph (13 km/h). More than that, it was limited to 4 mph (6.4 km/h).

These accidents, plus all the other non-fatal ones, started raising concerns about how safe this new automobile thing was for everyone (both drivers and pedestrians) and, as cars became more and more powerful and were able to go faster, new safety features started being invented. The first device that was specifically created to improve safety was the four wheel hydraulic brake system that was introduced on the Duisburg model A (if you remember, we wrote about it in our article about innovations that were made popular by Indy car racing). Other safety elements soon to be introduced were the safety glass (standard on all new Fords starting with 1930), seat belts and padded dashboards. All these improvements made driving a lot safer, but further and more serious actions had to be taken since cars were already able to travel as fast as 100 mph or even more.

That’s when car manufacturers understood that simply adding some features didn’t make their models safe, and that this aspect has to be taken into consideration throughout the entire development process. And in 1934, General Motors performed the first barrier crash test in the world at its Milford, Michigan Proving Ground. But the first thorough research of vehicle safety was conducted by Wayne State University in Detroit. In the late ‘30s, researchers here started looking into what exactly happened to the human body during a violent impact such as a high speed crash.

But biomechanics was still a young arm of science and not many things were known, so scientists had to find some test subjects that provided relevant results. In the beginning they used cadavers. They simply strapped cadavers fitted with accelerometers in cars and crashed the hell out of them. Of course, as you can imagine, this raised a lot of moral and ethical issues. But, perhaps the most important, some believed these results were not relevant, because cadavers couldn’t be used twice so reliable comparison data was pretty hard to achieve. Other researchers were crazier and volunteered to serve as dummies. After plenty of injuries and countless testing, gathered results were extremely valuable, but still, with live subjects, the impact’s force could not go above a certain level, or else the subject would die or suffer serious injuries. Different attempts were made using pigs, but everyone agreed that even though valuable, these tests were also not relevant.

All these tests eventually proved extremely useful in the development of the crash test dummy, a “test device” that simulated the human body. The first known crash test dummy was called “Sierra Sam” and was created by Samuel W. Alderson. Like many popular car features, the dummy was created for the aircraft industry, to test elements such as ejection seats or pilot restraint harnesses. After Sierra Sam, Alderson’s company, Alderson Research Labs (ARL) created a dummy that was later used for testing both aircrafts and motor vehicles.

In time, crash tests became more and more popular, especially due to the rising number of road fatalities and today many customers want to know a vehicle’s safety rating before deciding to buy it. That’s why every major market has at least one organization whose purpose is to independently crash test new models and award them safety rankings. All these programs are destined to offer an independent assessment of how safe a car is, because the most important tests are still the ones made by car makers. For example, the first crash test dummies were so popular with car manufacturers, that Alderson created the VIP-50 series, which was a series of dummies built specifically for Ford and General Motors.

And even today, car manufacturers usually have huge testing facilities where they crash a car in almost every imaginable way to make sure they won’t get embarrassed when the official ratings come out. Because there are a few examples of low crash test ratings being responsible for a model’s commercial failure: Rover 100 sales dropped like crazy after EuroNCAP gave it only one star for Adult Occupant Rating, the Daewoo Kalos received only two stars and sales were extremely slow, while the Isuzu Trooper was considered a car likely to roll over during sudden maneuver by Consumer Report and sales plummeted, with the model being pulled out of production two years later.

So, what types of tests do car manufacturers and testing organization usually perform on a car before awarding it a safety rating? Each one has its different testing policy, but a number of tests are extremely popular and common for most of them:

Frontal crash tests

This is one of the most common and most dangerous types of impacts and most people only think about this particular test when talking about crash testing in general. During this test, the vehicle is projected towards a solid obstacle at a predesigned velocity. The obstacle can either be a concrete wall or a barrier.

What carmakers try and achieve with these tests is to create an efficient “survival cell” that limits as much as possible the amount of external elements that might enter this cell and injure the car’s occupants. These external elements can be a part of the car’s body, a suspension element or any other car part not matter how small, because at high speed these can immediately become lethal. To better evaluate the effects a crash has on the human body, car manufacturers and testing organization use advanced dummies that are equipped with measuring instruments, so researchers can get accurate details about how big the impact forces are during the crash and what the human body has to endure.

Another version of the frontal impact test involves a crash between two vehicles. This type of tests give a better picture about what exactly happens to passengers during the crash, but, as you can probably imagine, are also more expensive and that’s why car manufacturers usually perform more tests that involve a solid obstacle.

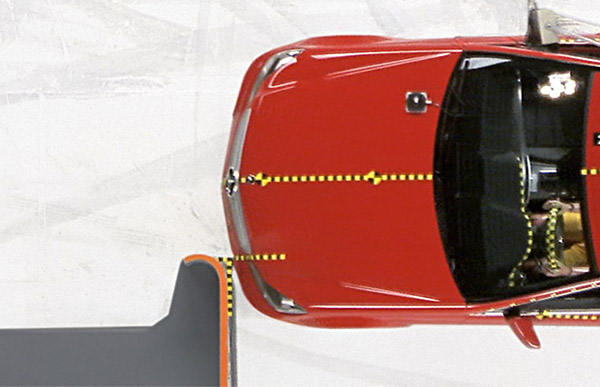

Offset tests

These tests are somehow similar to the frontal impact tests, but the difference is that only a part (smaller or larger, usually around half) of the car impacts the obstacle, whether it’s a wall, barrier or another car. This test is extremely important (perhaps even more important than the frontal crash one), because even though the impact area isn’t as large, the impact forces are almost as high as with the full frontal crash. This means that a smaller part of the car is responsible with absorbing all the impact force and this represents a challenge for car manufacturers, especially with this type of impacts being quite frequent (perhaps the most frequent one is when a driver tries to turn around without properly looking for other cars coming from the other way). Also, during this kind of crashes, a rotation force appears which makes one or both cars spin.

Side impact tests

These tests are performed to simulate crashes that usually take place in intersections. Engineers performing these tests usually use two vehicles or a vehicle being hit by a steel structure with wheels that simulates another vehicle. The test is used to determine how efficient crumple zones are, how large is the deformation and how many elements enter the “survival cell”. Given the mechanics of this crash, it is one of the most dangerous ones and most likely to produce serious injuries or even death, because the side of the car doesn’t have a crumple zone big enough to absorb all the impact energy. That’s why car manufacturers went through a lot to equip their cars with side airbags, one of the most important safety features a car can get because it protects the upper torso and prevents the head from passing through the window.

Roll Over Tests

I don’t think we should mention that these crashes are one of the most dangerous one a human can experience. So how do testing programs reproduce these situations? They put the car on a laterally inclined platform, speed it up and then crash it on its roof, to check out how much the roof has to suffer and, indirectly, how serious do passengers get injured. One of the most important elements during these crashes are the pillars holding the roof (the stronger and better engineered, the safer the passenger). These types of crashes are usually caused by speeding during corners, not handling the car properly on inclined terrain or after a high speed impact with another vehicle or an obstacle that sends the vehicle airborne.

Small Overlap Tests

This is another type of frequent accidents, when a car hits a small roadside solid object such as poles, trees or road signs. The test is extremely demanding for the vehicle’s structure at any speed, because most of the force is loaded onto the structure.

New versus Old

Sometimes, car manufacturers want to see how well a new generation of a model performs when crashed into an older one. This is usually done to check out previous generation’s safety level or highlight how much safety was improved on the new model. This test can involve multiple tests listed above, such as frontal, side or roll over.

Computer simulated test

Current technology allows a very accurate simulation of what happens when two vehicles hit each other. This way, testing facilities can simulate all kind of impact tests and evaluate the effects without physically damaging any vehicles. However, this test is not used to determine any rankings instead it is usually used before a live test, to make sure every setting is perfect so the results will be as relevant as possible without having to redo the test.

Major crash test programs

Each day, more than 3,000 people die in traffic related accidents. Most of these accidents have multiple cars involved, but a third of all fatalities are caused by a single vehicle. And with cars today being extremely fast (and that speed is more than affordable), that’s why huge efforts are made to make the streets safer for everyone, driver, passenger or pedestrian. Perhaps this effort can only be matched by the one made to lower emissions levels.

Like we said, besides each car manufacturer’s testing facilities, each major market also has an important safety programs (run by a governmental or independent organization) which runs crash tests and releases results without leaving any doubts about how accurate these are.

In the United States crash tests are performed by the National Highway Traffic Safety Administration (NHTSA) since 1979 and, starting with 1995, by the Insurance Institute for Highway Safety (IIHS). Unlike most of the other programs, the one in the United States is extremely important because if the NHTSA thinks a vehicle is not safe, they can block that model’s import or sales until it meets certain safety standards. On the other hand, each year the organization hands Top Safety Pick awards to the best performing models in what concerns safety. An even higher award, Top Safety Pick+ is given to the safest vehicles on the market.

In Europe, independent testing is performed by the European New Car Assessment Programme (Euro NCAP). The independent organization was founded in 1997 by the Transport Research Laboratory for the U.K. Department for Transport. Today, it is being backed up by the European Union, but testing is not mandatory and, unlike the United States, cars can still be sold even though they perform terrible. Testing is usually done either by the organization independently selecting models or by manufacturers voluntarily getting their models tested. Great results during these tests usually looks good for a certain model or brand’s image, but bad results are even more important, because there’s no better way of chase away European customers than to fail one or more of these tests.

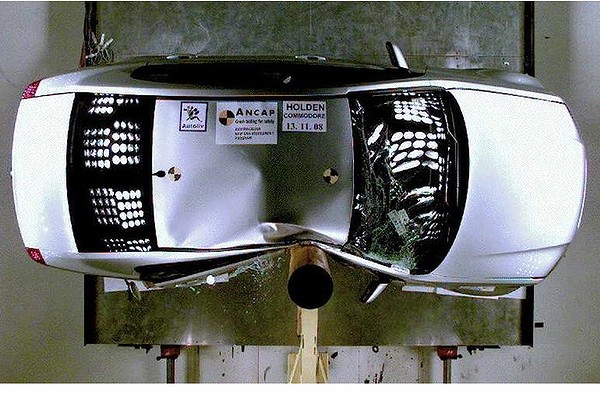

The Australasian New Car Assessment Program (ANCAP) is responsible for crash testing models sold in Australia and New Zealand, with the testing procedure being quite similar to the Euro NCAP.

There are also several other important testing programs in other parts of the world: Japan has the Japan New Car Assessment Program (JNCAP), China has the China New Car Assessment Program (C-NCAP), Russia has Auto Review Car Assessment Program (ARCAP) and Latin America and the Caribbean have the Latin New Car Assessment Program (Latin NCAP). And even though it’s not considered as important as the Euro NCAP, another popular European testing program is the one performed by ADAC, Germany and Europe’s largest automobile club, with more than 18 million registered members.

But perhaps one of the most popular testing programs on this list is the Euro NCAP, which has a distinct testing procedure that involves several tests, with seven of them being extremely important in the final ratings. These tests are:

Frontal Impact Test – These are performed at a speed of 64 km/h (40 mph), with the vehicle hitting a deformable offset barrier. Results are obtained after analyzing readings from sensors placed inside the car and on the dummies. Like we said, in our days, dummies are extremely advanced and simulate the human body almost perfectly.

Car to Car Side Impact Test – The vehicle is hit on the driver’s side by a mobile deformable barrier traveling at 50 km/h (31 mph). An important part of the test is evaluating how the car side intrudes and almost all cars going through this test are equipped with side airbags.

Pole Side Impact Test – The test involves a vehicle being projected sideways into a rigid pole at 29 km/h (18 mph). The pole’s diameter is 254 mm (10 inches) and it seriously damages the car.

Child Protection Test – For this test, Euro NCAP uses special child sized dummies placed inside the car in a child car seat recommended by the car manufacturer. The dummies, which are equipped with special sensors, simulate children aged between one and a half and three years old. Besides the child seat recommended by the carmaker, Euro NCAP also tests some of the most popular child seats to assess the vehicle’s overall child safety.

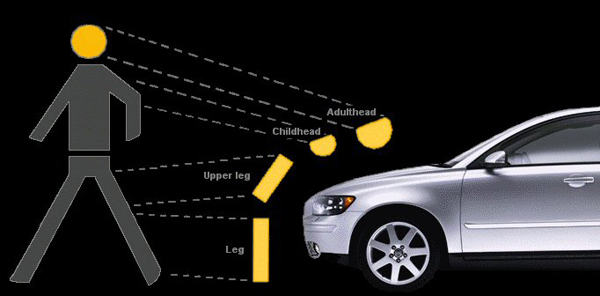

Pedestrian Protection Test – To see how much damage would a car do to a pedestrian, the organization performs tests at 40 km/h (25 mph). What’s interesting is that the tests aren’t performed on full dummies, Euro NCAP explaining that more relevant results are being obtained by using only parts of the dummy, such as legs or head, because they’re able to better control how the vehicle hits specific body parts.

Whiplash Test – The test is designed to evaluate the damage to the spine caused by a rear impact, even though the medical world still doesn’t offer a full explanation on how exactly these injuries take place. During this test, they evaluate the seat design, which should offer good head restraint geometry, how easy it is to adjust the seat and also how much overall integrity the tests use.

ESC Test – According to Euro NCAP, the Electronic Stability Control is one of the most important safety features a car can have, that’s why they’ve been recommending it as standard on new cars ever since 2008. And that’s also why all cars without it automatically get penalized. As for the test itself, it’s something similar to the Moose Test, simulating a sudden double lane change maneuver performed at 80 km/h (50 mph).

So…now that you know more about these crash tests, how much do you trust them? Do you usually make your decision when buying a new car based on these tests?