Low Pressure Steam Safety Valves - Capacities (original) (raw)

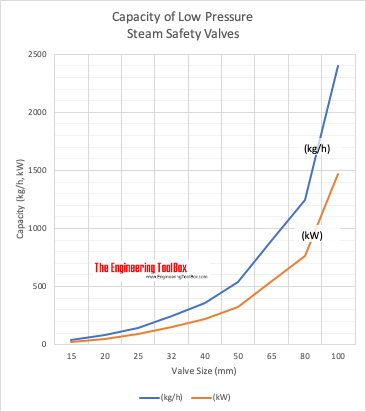

Sizing safety valves after boiler output power in low pressure systems (kW and Btu/hr).

The main purpose of a safety valve is to prevent the pressure in a system to exceed the certification pressure. Above certification pressure, no one can guaranty the systems safety - and especially for a steam system with very hot gas with huge amount of latent heat, the consequences can be dramatically.

The size of the safety valve depends primarily on the maximum boiler output and the operation pressure of the system. The safety valve shall as minimum have the evacuation capacity of all the vapor the boiler can produce running at full power at working (or certification) pressure.

The table below can be used to select a typical safety valve based on boiler output. Before final design, always consult the manufactures documentation.

Low Pressure Steam Safety Valves - Capacities

| Pipe SizeDN | Capacity | Maximum Boiler Output | |||

|---|---|---|---|---|---|

| (in) | (mm) | (kg/h) | (lb/h) | (kW) | (Btu/h) |

| 1/2 | 15 | 38 | 86 | 23 | 81 270 |

| 3/4 | 20 | 82 | 185 | 50 | 174 825 |

| 1 | 25 | 145 | 324 | 89 | 306 180 |

| 1 1/4 | 32 | 249 | 557 | 152 | 526 365 |

| 1 1/2 | 40 | 360 | 807 | 220 | 762 615 |

| 2 | 50 | 536 | 1 199 | 328 | 1 133 055 |

| 2 1/2 | 65 | 901 | 2 012 | 551 | 1 901 340 |

| 3 | 80 | 1 244 | 2 779 | 761 | 2 626 155 |

| 4 | 100 | 2 397 | 5 355 | 1 465 | 5 060 475 |

Note! The table above is based on low pressure steam of 100 kN/m2 (1 bar) or 15 psi in imperial units. Latent heat of saturated steam is 2201 kJ/kg (945 Btu/lb).

- 1 N/m2 = 1 Pa = 1.4504×10-4 lb/in2 (psi) = 10-5 bar

- For higher pressure, steam is compressed and require less volume - required size of the valve reduced

- For lower pressure, steam is expanded and require more volume - required size of the valve increased

Related Topics

Sizing and dimensions of control valves & equipment in steam and condensate systems.

Risk, reliability and safety in process control systems.

Design of steam & condensate systems with properties, capacities, sizing of pipe lines, system configuration and more.

Related Documents

Safety Valve Standards

The most common used safety valve standards in Germany, UK, USA, France, Japan, Australia and Europe.