Piping Materials - Temperature Heat Expansion and Cooling Contraction (original) (raw)

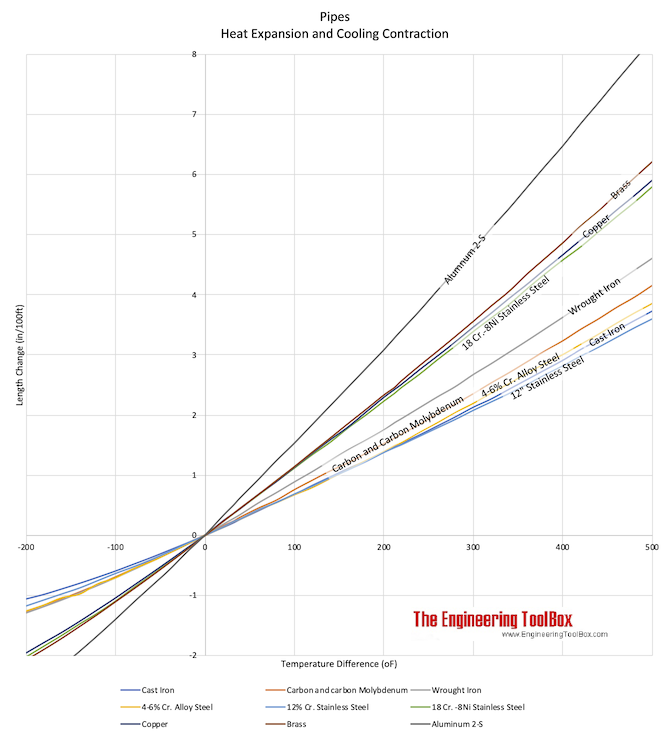

Expansion and contraction when cast iron, carbon and carbon molybdenum steel, wrought iron, copper, brass and aluminum pipes are heated or cooled.

Temperature expansion of pipes or tubes with some commonly used materials:

For full table with wrought iron, stainless steel, copper, brass and aluminum - rotate the screen!

Piping Materials - Temperature Heat Expansion and Cooling Contraction

| Saturated Steam Pressure1)(psi) | Temperature (oF) | Temperature Expansion of Pipes (in/100 ft) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cast Iron | Carbon and carbon Molybdenum | Wrought Iron | 4-6% Cr. Alloy Steel | 12% Cr. Stainless Steel | 18 Cr. -8Ni Stainless Steel | Copper | Brass | Aluminum 2-S | ||

| -200 | -1.058 | -1.282 | -1.289 | -1.250 | -1.170 | -2.030 | -1.955 | -2.065 | -2.69 | |

| -180 | -0.982 | -1.176 | -1.183 | -1.150 | -1.070 | -1.850 | -1.782 | -1.890 | -2.44 | |

| -160 | -0.891 | -1.066 | -1.073 | -1.030 | -0.970 | -1.670 | -1.612 | -1.705 | -2.18 | |

| -140 | -0.797 | -0.948 | -0.955 | -0.970 | -0.870 | -1.480 | -1.428 | -1.508 | -1.93 | |

| -120 | -0.697 | -0.826 | -0.833 | -0.800 | -0.750 | -1.300 | -1.235 | -1.308 | -1.67 | |

| -100 | -0.593 | -0.698 | -0.705 | -0.700 | -0.630 | -1.100 | -1.040 | -1.098 | -1.40 | |

| -80 | -0.481 | -0.563 | -0.570 | -0.550 | -0.520 | -0.880 | -0.835 | -0.888 | -1.12 | |

| -60 | -0.368 | -0.428 | -0.435 | -0.430 | -0.400 | -0.670 | -0.630 | -0.673 | -0.85 | |

| -40 | -0.248 | -0.288 | -0.295 | -0.290 | -0.270 | -0.450 | -0.421 | -0.452 | -0.58 | |

| -20 | -0.127 | -0.145 | -0.152 | -0.145 | -0.130 | -0.225 | -0.210 | -0.227 | -0.28 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | 0.128 | 0.148 | 0.180 | 0.140 | 0.140 | 0.223 | 0.238 | 0.233 | 0.32 | |

| 32 | 0.209 | 0.230 | 0.280 | 0.234 | 0.234 | 0.356 | 0.366 | 0.373 | 0.50 | |

| 29.39 | 40 | 0.270 | 0.300 | 0.350 | 0.280 | 0.280 | 0.446 | 0.451 | 0.466 | 0.63 |

| 60 | 0.410 | 0.448 | 0.540 | 0.430 | 0.430 | 0.669 | 0.684 | 0.690 | 0.93 | |

| 28.89 | 80 | 0.550 | 0.580 | 0.710 | 0.600 | 0.580 | 0.892 | 0.896 | 0.920 | 1.24 |

| 27.99 | 100 | 0.680 | 0.753 | 0.887 | 0.650 | 0.690 | 1.115 | 1.134 | 1.150 | 1.53 |

| 26.48 | 120 | 0.830 | 0.910 | 1.058 | 0.800 | 0.820 | 1.338 | 1.366 | 1.390 | 1.84 |

| 24.04 | 140 | 0.970 | 1.064 | 1.240 | 0.950 | 0.960 | 1.545 | 1.590 | 1.625 | 2.15 |

| 20.27 | 160 | 1.110 | 1.200 | 1.420 | 1.100 | 1.090 | 1.784 | 1.804 | 1.865 | 2.46 |

| 14.63 | 180 | 1.240 | 1.360 | 1.580 | 1.250 | 1.230 | 2.000 | 2.051 | 2.100 | 2.77 |

| 6.45 | 200 | 1.390 | 1.520 | 1.750 | 1.400 | 1.380 | 2.230 | 2.296 | 2.340 | 3.08 |

| 0 | 212 | 1.480 | 1.610 | 1.870 | 1.500 | 1.460 | 2.361 | 2.428 | 2.467 | 3.28 |

| 2.5 | 220 | 1.530 | 1.680 | 1.940 | 1.550 | 1.510 | 2.460 | 2.516 | 2.580 | 3.41 |

| 10.3 | 240 | 1.670 | 1.840 | 2.120 | 1.720 | 1.650 | 2.680 | 2.756 | 2.830 | 3.73 |

| 20.7 | 260 | 1.820 | 2.020 | 2.300 | 1.880 | 1.790 | 2.920 | 2.985 | 3.070 | 4.07 |

| 34.5 | 280 | 1.970 | 2.180 | 2.470 | 2.050 | 1.930 | 3.150 | 3.218 | 3.315 | 4.40 |

| 52.3 | 300 | 2.130 | 2.350 | 2.670 | 2.200 | 2.080 | 3.390 | 3.461 | 3.565 | 4.74 |

| 74.9 | 320 | 2.268 | 2.530 | 2.850 | 2.370 | 2.220 | 3.615 | 3.696 | 3.820 | 5.10 |

| 103.3 | 340 | 2.430 | 2.700 | 3.040 | 2.530 | 2.360 | 3.840 | 3.941 | 4.065 | 5.43 |

| 138.3 | 360 | 2.590 | 2.880 | 3.230 | 2.700 | 2.510 | 4.100 | 4.176 | 4.350 | 5.78 |

| 180.9 | 380 | 2.750 | 3.060 | 3.425 | 2.860 | 2.670 | 4.346 | 4.424 | 4.610 | 6.13 |

| 232.4 | 400 | 2.910 | 3.230 | 3.620 | 3.010 | 2.820 | 4.580 | 4.666 | 4.870 | 6.47 |

| 293.7 | 420 | 3.090 | 3.421 | 3.820 | 3.180 | 2.980 | 4.800 | 4.914 | 5.150 | 6.84 |

| 366.1 | 440 | 3.250 | 3.595 | 4.020 | 3.350 | 3.130 | 5.050 | 5.154 | 5.400 | 7.19 |

| 451.3 | 460 | 3.410 | 3.784 | 4.200 | 3.530 | 3.290 | 5.300 | 5.408 | 5.680 | 7.55 |

| 550.3 | 480 | 3.570 | 3.955 | 4.400 | 3.700 | 3.450 | 5.540 | 5.651 | 5.950 | 7.90 |

| 664.3 | 500 | 3.730 | 4.151 | 4.600 | 3.860 | 3.600 | 5.800 | 5.906 | 6.220 | 8.25 |

| 795.3 | 520 | 3.900 | 4.342 | 4.810 | 4.040 | 3.760 | 6.050 | 6.148 | 6.500 | 8.61 |

| 945.3 | 540 | 4.080 | 4.525 | 5.020 | 4.200 | 3.930 | 6.280 | 6.410 | 6.780 | 8.98 |

- Vacuum in degree below 211 oF, psi gauge above 211 oF

- T (oC) = 5/9 (T (oF) - 32)

- 1 in (inch) = 25.4 mm

- 1 ft (foot) = 0.3048 m

- How to calculate thermal expansion of pipes?

- Expansion coefficients common materials

Related Topics

Dimensions of steam and condensate pipe lines. Calculate pressure losses, recommended velocities, capacities and more.

Thermal expansion and expansion coefficients. Expansion pipes and tubes made of stainless steel, carbon steel, copper, plastics and more.

Related Documents

Steel Pipes Expansion Loops - Design and Calculation

Steel pipe expansion loops and their importance in managing thermal expansion, and how to design and size them effectively. Key considerations, calculations, and installation tips to prevent stress and damage in piping systems.

Our Mission

The Engineering ToolBox provides a wide range of free tools, calculators, and information resources aimed at engineers and designers. It offers detailed technical data and calculations for various fields such as fluid mechanics, material properties, HVAC systems, electrical engineering, and more.

The site includes resources for common engineering tasks, such as calculating physical properties (e.g., density, viscosity, thermal conductivity), converting units, and designing systems like heating and water distribution.

With sections on everything from acoustics to hydraulics, it serves as a comprehensive tool for both students and professionals in technical and engineering disciplines.

About the Engineering ToolBox!

Privacy Policy

We don't collect information from our users. More about

We use a third-party to provide monetization technology for our site. You can review their privacy and cookie policy here.

You can change your privacy settings by clicking the following button: .

Citation

This page can be cited as

- The Engineering ToolBox (2003). Piping Materials - Temperature Heat Expansion and Cooling Contraction. [online] Available at: https://www.engineeringtoolbox.com/thermal-expansion-steam-pipes-d\_358.html [Accessed Day Month Year].

Modify the access date according your visit.