M30 Guided Multiple Launch Rocket System (MLRS) (original) (raw)

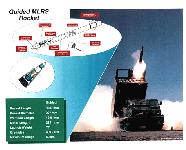

The United States entered into a cooperative Engineering and Manufacturing Development (EMD) program with the United Kingdom, Germany, France and Italy to develop a new guided rocket for the Multiple Launch Rocket System. The rocket, known as the M30 GMLRS, will have increased range, accuracy and lethality. The GMLRS EMD represents another example of international cooperation to produce a common product to achieve interoperability, while sharing and minimizing costs and risks.

The United States entered into a cooperative Engineering and Manufacturing Development (EMD) program with the United Kingdom, Germany, France and Italy to develop a new guided rocket for the Multiple Launch Rocket System. The rocket, known as the M30 GMLRS, will have increased range, accuracy and lethality. The GMLRS EMD represents another example of international cooperation to produce a common product to achieve interoperability, while sharing and minimizing costs and risks.

Prime contract for the EMD phase was awarded on 4 November 1998 to Lockheed Martin Vought Systems (LMVS) by the US on behalf of the GMLRS partner nations. The EMD contract is a Cost Plus Award Fee (CPAF) type contract worth approximately $121 million and was scheduled to be completed in 48 months. LMVS was selected based on its previous experience and involvement with MLRS launchers and rockets.

The GMLRS EMD contract is one of the first Army programs to use the "Alpha Acquisition" contracting process in which the Integrated Product Team (IPT) approach is used to arrive at an acceptable contract between the prime and the Government in a timely manner. This approach includes the reduction of procurement timelines through the elimination of unnecessary stages, by the adoption of partnering agreements between the contractor and the Government, and by the establishment of collaborative IPTs.

Final plans for GMLRS production in the US and Europe are still being formulated. US production is scheduled to begin in FY02 with a planned buy of approximately 100,000 rockets.

The U.S. Army Aviation and Missile Command (AMCOM) Research, Development and Engineering Center (RDEC), with support from industry, conducted an Advanced Technology Demonstration (ATD) to design, fabricate, and flight test a low cost guidance and control (G&C) package for the Extended Range MLRS rocket.

The Guided Multiple Launch Rocket System (MLRS) Advanced Technology Demonstration [ATD 95-98] demonstrated a significant improvement in the range and accuracy of the MLRS free-flight artillery rocket. Improved accuracy results in a significant reduction in the number of rockets required to defeat the target (as much as sixfold at extended ranges). Other benefits include an associated reduction in the logistics burden (transportation of rockets), reduced chances of collateral damage and fratricide, reduced mission times (resulting in increased system survivability), and increased effective range for the MLRS rocket. The ATD designed, fabricated, and flight-tested a low cost guidance and control package to be housed in the nose of the rocket, thus minimizing the changes to the current rocket. The Phase I G&C package, consisting of alow cost inertial measurement unit (IMU), a flight computer, and canards driven by electro-mechanical actuators, will be housed in the nose section of the rocket and will result in a significant increase in rocket delivery accuracy. The IMU package will provide a 2�3 mil accuracy sufficient for some MLRS warheads with the GPS-aided package providing a 10 meter CEP accuracy for warheads which require precision accuracy. The package to be demonstrated will result in a rocket which is more cost effective and more lethal while requiring no change to crew training procedures or maintenance procedures (during the 15-year shelflife). The guidance and control package will be designed with applicability to bomblet, mine, precision guided submunition, and unitary/earth penetrator warheads. A second phase of the demonstration will add a Global Positioning System (GPS) receiver and antenna to demonstrate near precision delivery (5 meters CEP).

In 1994, the Missile Research, Development, and Engineering Center (MRDEC) initiated the Guided MLRS Advanced Technology Demonstration (ATD) with the support of the MLRS Project Office and the TRADOC System Manager for Rockets and Missiles. From the start, the ATD's exit criteria included not only accuracy improvements, but also a production cost goal of $12k for the guidance and control package, a zero maintenance requirement for the rocket, and a shelf-life of at least 15 years.

The design, fabrication, and testing of the guidance and control package took place within the MRDEC. The thermal battery, IMU, and GPS receiver were purchased off-the-shelf and tested by the MRDEC. The control actuation system, guidance computer, and all missile software were designed in-house by the MRDEC. The GPS antennas were designed and fabricated by the Army Research Laboratory. The canards, spring-opening tailfin assembly, telemetry package, roll bearing, missile skin sections, and wiring harnesses were designed and fabricated by LMVS. The MRDEC assembled the rocket and performed all system testing.

On May 13, 1998, a fully successful first flight of the Guided MLRS was conducted at White Sands Missile Range, New Mexico. This flight was launched from an M270 launcher, flown to a range of 49 km, demonstrated the proper operation of all missile subsystems, and achieved the 3-mil accuracy (150 meters at 49 km) goal when navigating in pure inertial mode using a Honeywell HG1700 IMU. Given the level of success on the first flight, the second flight was changed from an inertial flight to a GPS-aided flight. However, due to a bug in the vendor's GPS receiver software, only three satellites were tracked and the missile again flew a successful inertial flight using a Honeywell IMU. The third flight was conducted with the Litton LN-200 IMU. All subsystems performed well except for the IMU, which did not meet the accuracy goal. The fourth flight experienced a catastrophic tailfin failure at launch as well as an electrical short in the umbilical. After a root cause failure analysis and further tailfin testing, an adjustment was made to the tailfin assembly and a blocking diode was added to prevent umbilical shorts from damaging the rocket's electronics. The ATD culminated on February 11, 1999 with a GPS-aided flight test in which the missile again flew 49 km and impacted only 2.1 meters from the target center, a resounding success.

The ATD successfully demonstrated all of its goals and has transitioned to the MLRS Project Office for a 4-year engineering, manufacturing, and development (EMD) phase. The EMD will be conducted as an international program with the United Kingdom, Italy, Germany and France. Current plans call for subsequent U.S. production of 90k rounds with the DPICM warhead. The accuracy demonstrated in flight number five's GPS-aided mode opens the door for future consideration of various MLRS unitary warheads and the addition of point targets to the MLRS target set.

MLRS Smart Tactical Rocket (MSTAR)

The Fiscal Year 2001 Army budget request included decisions to restructure or "divest" a number of programs in order to provide some of the resources to support its transformation to achieve the ambitious deployment goals outlined in the October 1999 Army Vision. The restructured programs are the Crusader and the Future Scout and Cavalry System. The "divestitures" include Heliborne Prophet (Air), MLRS Smart Tactical Rocket (MSTAR), Stinger Block II, Command and Control Vehicle (C2V), Grizzly, Wolverine, and the Army Tactical Missile System Block IIA. Funding for these programs was reallocated to fund the Army Vision transformation strategy.

SYSTEM DESCRIPTION:

The MLRS Smart Tactical Rocket is the next step in the evolution of the MLRS Rocket. The MSTAR will be a Guided (MSTAR) rocket carrying terminally guided, smart submunitions to a maximum range of approximately 60 km. After dispense, these munitions will use onboard sensors to detect and engage stationary or moving targets. An Advanced Technology Demonstration (ATD) is scheduled to begin in FY98, followed by EMD beginning in FY02.

SYSTEM CHARACTERISTICS:

Four candidate submunitions, P3I BAT, SADARM, LOCAAS, and Damocles are being evaluated to determine which one best meets Army requirements. Each candidate carries a sensor suite to detect, classify and engage high value targets. They use either explosively formed penetrators or shaped charges to penetrate armor.