beam homogenizers (original) (raw)

Definition: devices for producing beam profiles with homogeneous intensity distribution

- optical elements

- achromatic optics

- adaptive optics

- aspheric optics

- custom optics

- diffractive optics

- fiber optics

- flat optics

- large diameter optics

- laser optics

- nonlinear optics

- optical elements for imaging

- polarization optics

- refractive optical elements

- reflective optical elements

- beam splitters

- beam collimators

- beam expanders

- beam homogenizers

- diffusers

- group velocity delay compensation plates

- optical apertures

- optical attenuators

- optical filters

- optical modulators

- optical windows

- phase corrector plates

- (more topics)

Related: beam shaperslaser beamsflat-top beamsoptical intensitydiffractive opticsmicro-optics

Page views in 12 months: 2255

DOI: 10.61835/zyk Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

📦 For purchasing beam homogenizers, use the RP Photonics Buyer's Guide — an expert-curated directory for finding all relevant suppliers, which also offers advanced purchasing assistance.

Contents

What are Beam Homogenizers?

Beam homogenizers are optical devices which are used to modify a laser beam (or sometimes some other light beam) such that one obtains a nearly constant optical intensity over some area, and negligible intensity outside that area. Such flat-top beams are required for some applications, in particular for some forms of laser material processing and optical lithography (e.g. for computer chip manufacturing), where one needs to expose a certain area on a workpiece to a well-defined amount of optical radiation.

Beam homogenizers generally apply a random or quasi-random change to the amplitude profile of a beam, and in this aspect they profoundly differ from beam shapers, which work in a deterministic manner.

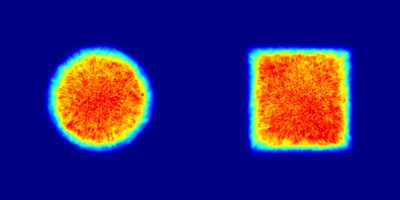

Many beam homogenizers produce the needed homogenized beam profile in a focal plane, while others do that for the far field. The shape of the produced intensity profile is often a square, in other cases a circle.

The generated beam profile is generally not perfectly flat, but exhibits some level of random fluctuations, sometimes also relatively regular interference patterns. Depending on the requirements of the application, somewhat sophisticated operation principles are required to obtain a sufficiently high quality of homogenization in conjunction with a high enough optical efficiency.

Operation Principles

The operation principles of beam homogenizers can vary substantially and often involve sophisticated considerations. Conceptually simple approaches like using a simple random diffuser plate is often not sufficient, since the required quality of homogenization could not be achieved together with a high optical efficiency, i.e., with a high optical power throughput. Therefore, more advanced concepts have been developed:

- Some beam homogenizers are best explained based on Fourier optics. For example, they can be based on a microlens array placed in a conjugate plane and also contain Fourier lenses.

- Some homogenizers work on the basis of imaging, but there are also non-imaging designs, e.g. based on waveguides (light pipes, e.g. homogenizing rods) or multimode fibers. They work best with polychromatic non-collimated light inputs.

- Besides, there are other types of micro-optic diffractive elements, partly with pseudo-random structures, used in other types of homogenizers.

- When a highly coherent input beam is used, it is sometimes necessary to also apply a rotating diffuser plate — a concept which works only for continuous-wave beams, not for short laser pulses.

Which operation principle is most suitable for an application generally depends on the detailed requirements and on the coherence properties of the input beam. The Fresnel number is sometimes taken as a criterion for the choice of such methods.

Frequently Asked Questions

What is a beam homogenizer?

A beam homogenizer is an optical device used to modify a light beam to have a nearly constant intensity over a specific area, creating a so-called flat-top beam. This is required for applications like laser material processing and optical lithography.

How do beam homogenizers differ from beam shapers?

The main difference is their method of operation. Beam homogenizers apply random or quasi-random changes to the beam's profile, whereas beam shapers modify the beam in a purely deterministic, predictable manner.

What are operation principles used in beam homogenizers?

Common operation principles involve using microlens arrays, waveguides like light pipes or multimode fibers, and diffractive optical elements. For highly coherent beams, a rotating diffuser may be used to average out interference effects.

Is the beam profile from a homogenizer perfectly flat?

No, the resulting profile is generally not perfectly flat. It typically exhibits some level of random intensity fluctuations and may also show regular interference patterns, depending on the device and the input beam's properties.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 22 suppliers for beam homogenizers. Among them:

⚙ hardware

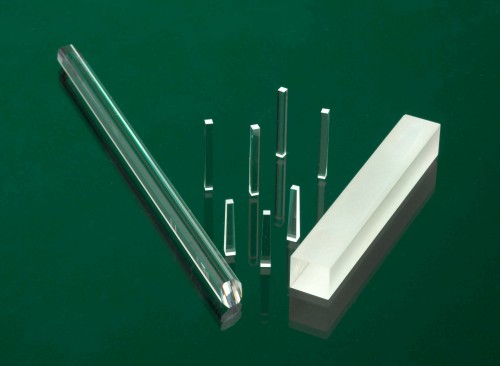

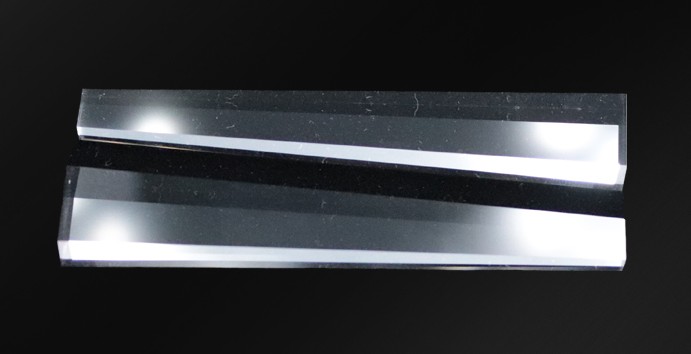

Knight Optical offers hexagonal homogenising light pipes which provide uniform illumination from non-uniform polychromatic light sources through the process of total internal reflection. Manufactured from fused silica, these light pipes achieve an approximate 35-40% increase in the output of light. Custom beam homogenisers are available including tapered light pipes.

⚙ hardware

Avantier provides light pipes that can serve as beam homogenizers. These pipes can be either straight or bent at an angle of up to 90°. The light pipes are coated with a five-layer coating that facilitates light transmission while minimizing losses.

⚙ hardware

Edmund Optics offers a variety of light pipes, including hexagonal and tapered light pipe homogenizing rods. The hexagonal rods are made of N-BK7 or fused silica, the fused silica version is ideal for applications utilizing UV LED light sources. The tapered pipes are offered with several magnification options. Mounts are available to provide an easy system integration solution and easy handling.

⚙ hardware

IRD specializes in high-precision light homogenizers and light pipes. IRD manufactures traditional square and round homogenizers, as well as more exotic rectangular, hexagonal, and octagonal homogenizers, including straight and tapered designs. Their designs are optimized based upon your specific needs and requirements; typical materials include, but are not limited to, fused silica, nBK7, and sapphire.

⚙ hardware

The beam homogenizer from lightsource.tech works in the wavelength range for 350 nm to 2000 m, or 200 nm to 2000 nm with quartz glass optics. It offers extremely high homogeneity with a deviation of only ±2% and at the same time a transmission of more than 50% of the coupled light. This is made possible by a flyeye condenser, which is equipped with two microlens arrays with 400 lens elements each.

⚙ hardware

Shanghai Optics offers light pipes which can be used as beam homogenizers. They can be straight or bent pipes with a bending angle up to 90°. A five-layer coating ensures light transmission with low losses.

⚙ hardware

PowerPhotonic manufacture high quality beam homogenisers for single and multimode beams. These refractive homogenisers create a controlled, uniform profile that can withstand very high powers due to the LIDT of the fused silica used in production. Due to PowerPhotonic’s unique manufacturing process, customisation of the shape size and profile of the output beam is easy. Enquire now for more information on the different beam homogenisation options available.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

general optics

general optics