dichroic mirrors (original) (raw)

Definition: mirrors with significantly different reflection or transmission properties at two different wavelengths

Alternative terms: dual-wavelength mirrors, dual-band mirrors, dichroic reflectors

- mirrors

- dielectric mirrors

* Bragg mirrors

* quarter-wave mirrors

* dichroic mirrors

* chirped mirrors

* cold mirrors

* hot mirrors

- dielectric mirrors

Related: dichroismmirrorsdielectric mirrorsdielectric coatingsBragg mirrorsanti-reflection coatingsoptical filters

Page views in 12 months: 6907

DOI: 10.61835/1un Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

📦 For purchasing dichroic mirrors, use the RP Photonics Buyer's Guide — an expert-curated directory for finding all relevant suppliers, which also offers advanced purchasing assistance.

Contents

What are Dichroic Mirrors?

A dichroic mirror (or dual-band mirror, dual-wavelength mirror, dichroic reflector) is a mirror with significantly different reflection or transmission properties at two different wavelengths — actually meaning two wavelength regions of some often not so large width. The specifications often refer to frequently used laser lines, so that dichroic mirrors often belong to the category laser line optics.

There are also trichroic mirrors, having defined optical properties at three different wavelengths.

Some dichroic reflectors are used for broadband applications, e.g. for reflecting only ultraviolet light to some application but not so much infrared light which could lead to unwanted heating of the irradiated objects. Similar broadband devices are called hot mirrors or cold mirrors, depending on whether they reflect or suppress heat radiation.

The dichroic property relates to one of two possible meanings of the term dichroism.

Most dichroic mirrors are dielectric mirrors, but there are also crystalline mirrors where the multilayer structure consists of semiconductor materials. In both cases, the operation principle is that of a multilayer interference coating.

Designing Dichroic Mirrors

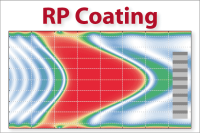

For designing mirror coatings, a flexible simulation and design software is indispensable. It must not only be able to calculate all relevant optical properties for a given design, but assist you in finding a suitable design for achieving given target properties. The RP Coating software is an ideal tool for such work, as it is particularly flexible. For example, you can start with a known type of mirror design, described with a few parameters, and optimize those very efficiently — if necessary, followed by a local optimization of all layer thickness values.

Short-pass and Long-pass Mirrors

In electronics, the terms low-pass and high-pass filter are common, where “low” and “high” refers to the frequency. In optics, where it is more common to refer to wavelengths, one uses the terms short-pass and long-pass mirror. Here, a short-pass mirror (or shortpass mirror) is one which has a high transmittance at short wavelengths and high reflectance at longer wavelengths; it could also be called a high-pass filter (referring to optical frequencies).

It can be challenging to make mirrors such that the wavelength with high transmittance and the wavelength with high reflectance are close together, as e.g. in Figure 2. They need more sophisticated designs and often also a higher precision of coating fabrication.

Applications of Dichroic Mirrors

Dichroic mirrors are applied for different purposes. Some examples:

- In a diode-pumped laser, a dichroic short-pass mirror in the resonator, placed next to the laser crystal, may be used for injecting pump light, while the circulating laser light is reflected to nearly 100%.

- In a laser with intracavity frequency doubling, a dichroic end mirror may couple out the harmonic light while fully reflecting the pump wave.

- In the case of external frequency doubling, a dichroic mirror may be used as harmonic separator (see Figure 1), i.e., as a kind of wavelength-dependent beam splitter.

- In laser microscopy (fluorescence microscopy), a dichroic mirror can be used for separating the fluorescence light (containing the image information) from the pump light.

- A similar situation occurs in various methods of spectroscopy, e.g. Raman spectroscopy.

Figure 1: Use of a dichroic mirror as a harmonic separator. The frequency-doubled light is reflected to nearly 100%, whereas most of the pump light is transmitted, although a few percent of it may still be reflected to the output port.

Design and Fabrication of Dielectric Mirrors

Most dichroic mirrors are fabricated as dielectric mirrors, e.g. with electron beam deposition, ion beam sputtering (IBS) or ion-assisted deposition (IAD). Semiconductor-based dichroic mirrors are fabricated with epitaxial techniques such as MOCVD or MBE.

Depending on the case, the design of the required layer structure may be possible based on analytical considerations, possibly followed by a numerical optimization, or entirely on numerical optimization, e.g. with a Monte-Carlo method. In many cases, the design involves a compromise between the obtained optical properties, the required number of layers, and the required growth precision.

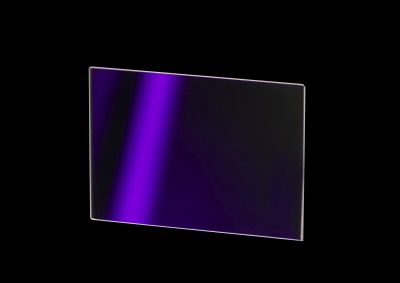

Figure 2: Reflectance spectrum of a dichroic mirror coating, designed with the software RP Coating for high transmittance (low reflectance) around 800–950 nm and high reflectance at 1064 nm.

For any dielectric mirror, the reflection spectrum (reflectance vs. wavelength) depends on the angle of incidence and (for non-normal incidence) also on the polarization of the input light. Only to a limited extent, mirror designs can be made such that the desired dichroic properties are achieved over some range of input angles.

As a dichroic mirror has to be transparent to light for at least one wavelength of interest, the quality (e.g. transmission losses) of the substrate material and possible reflections from the backside need to be considered. An anti-reflection coating on the backside can help to reduce such a reflection, and a slight wedge form of the substrate can often eliminate the effects of residual reflection.

Frequently Asked Questions

What is a dichroic mirror?

A dichroic mirror is an optical mirror with significantly different reflection or transmission properties at two different wavelengths or spectral regions. It reflects light in one wavelength range while transmitting light in another.

How do dichroic mirrors work?

Most dichroic mirrors are dielectric mirrors whose function relies on thin-film interference. For example, one wavelength may be within a Bragg reflection band while another lies outside that band.

What are common applications of dichroic mirrors?

They are often used to combine or separate light beams of different colors, for instance to inject pump light into a laser, separate harmonic light after frequency doubling, or isolate fluorescence light in microscopy and spectroscopy.

What is the difference between a short-pass and a long-pass mirror?

A short-pass mirror has a high transmittance for short wavelengths and a high reflectance for longer wavelengths. Conversely, a long-pass mirror transmits long wavelengths and reflects short ones.

How are dichroic mirrors manufactured?

They are typically fabricated by depositing a multilayer stack of dielectric materials onto an optical substrate. Common fabrication methods include ion beam sputtering (IBS) and ion-assisted deposition (IAD).

Does the performance of a dichroic mirror depend on the angle of incidence?

Yes, for any dielectric mirror, the reflection spectrum depends on the angle of incidence and, for non-normal incidence, also on the polarization of the light. Designs can be optimized for a certain range of angles.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 79 suppliers for dichroic mirrors. Among them:

⚙ hardware

Perkins Precision Developments (PPD) manufactures high energy laser mirrors, including dichroic and trichroic versions, for both prototype and volume OEM requirements. We apply custom Ion Beam Sputtered (IBS) thin film coatings for visible to near-infrared wavelengths on customer supplied substrates. PPD utilizes IBS coating technology because it is ideal for complex spectral designs, high power lasers and applications where it is critical to minimize losses from absorption and scatter.

💻 software💡 consulting

With the powerful software RP Coating, you can analyze and optimize optical thin-film multilayer coatings. The great flexibility of that software allows you, for example, to define an arbitrary figure-of-merit function describing your requirements.

⚙ hardware

A dichroic mirror, also down as a dual-band mirror, dual-wavelength mirror, or dichroic reflector, is a specialized mirror which has different optical properties at two different wavelengths.

⚙ hardware

OPTOMAN's IBS-coated dichroic mirrors feature spectral drift-free performance, which is why very sharp edge configurations are feasible. IBS coated wavelength separators feature spectral drift-free performance that allows very sharp edge configurations. OPTOMAN can make mirrors with transmittance over 99% and reflectance over 99.9%. Our Dichroic mirrors are optimized for high power laser applications providing the best possible extinction ratio between transmitted and reflected laser beams and feature minimum pulse dispersion.

Standard dichroic mirrors can be found in OPTOSHOP.

⚙ hardware

Artifex Engineering offers custom dichroic mirrors tailored to your requirements. Dielectric coatings are particularly developed for the respective application and enable precise wavelength ranges, so that individual wavelengths or selected ranges can be specified. Our mirrors can be manufactured in almost any shape: round, rectangular, elliptical, or any other shape including cut-outs and drill holes. Holes may also be drilled at an angle to the surface normal. Visit our product page for more information. We look forward to your inquiry.

⚙ hardware

UltraFast Innovations (UFI®) provides a wide range of laser mirrors, including dichroic mirrors e.g., for input and output coupling in ultrafast laser systems. In addition, these dichroic mirrors can be used for building a so-called wave synthesizer. Based on that technology, we have developed the first commercial light field synthesizer.

⚙ hardware

We design and manufacture custom dichroic filters between 300 and 6000 nm. Dichroic filters are often either a long pass filter reflecting the short waves and transmitting the long waves, or a short pass filter transmitting the shorter wavelengths and blocking the longer wavelengths, often at 45° AOI.

⚙ hardware

LASEROPTIK offers different types of multiline coatings for applications like nonlinear frequency conversion (harmonic separators), OPOs and others.

⚙ hardware

Shanghai Optics manufactures a wide range of optical filters or mirrors for engineering, scientific, and photographic applications. Our hard coated optical filters are dichroic filters/mirrors. They are composed of a single substrate with a dense hard coating. These hard sputtered filters are expensive to produce, but they have excellent performance and are ideal for applications where precision is of paramount importance. We use cutting-edge IBS technology to give our dichroic filters uniform dielectric coatings, and no adhesives whatever are involved in manufacture. This ensures a quality product with a very long filter life. Since they have only one substrate covered with a thin film, Shanghai Optics customized dichroic filters are much thinner than traditional coated filters and offer much higher transmission.

Bibliography

(Suggest additional literature!)

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

photonic devices

photonic devices