dispersion-flattened fibers (original) (raw)

Acronym: DFF = dispersion-flattened fiber

Definition: fibers with a non-standard zero dispersion wavelength

Category:  fiber optics and waveguides

fiber optics and waveguides

- dispersion-engineered fibers

- dispersion-shifted fibers

- dispersion-flattened fibers

- dispersion-decreasing fibers

Related: Dispersion Engineering for Telecom Fiberschromatic dispersiondispersion-engineered fiberstelecom fibers

DOI: 10.61835/sne Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

📦 For purchasing dispersion-flattened fibers, use the RP Photonics Buyer's Guide — an expert-curated directory for finding all relevant suppliers, which also offers advanced purchasing assistance.

Contents

What are Dispersion-flattened Fibers?

Dispersion-flattened fibers are a class of dispersion-engineered telecom fibers. They are designed so that their chromatic dispersion remains nearly constant — and often small — across a wide wavelength range, typically covering much of the low-loss transmission window of fused silica (around 1300–1625 nm).

An earlier dispersion-engineered fiber type is dispersion-shifted fibers, which have their zero dispersion wavelength shifted into the 1.5-μm telecom wavelength region. Such fibers have a substantial dispersion slope (specified with units of ps/(nm2 km), related to third-order dispersion), which can be problematic particularly in wavelength division multiplexing, where different signals experience substantially different GVD values. Even when only a single signal wavelength is used, it is inconvenient that the dispersion slope strongly restricts the usable wavelength range.

For such reasons, dispersion-flattened fibers with a much reduced dispersion slope, i.e., with relatively constant group velocity dispersion over some wavelength range, have been developed. In other words, they exhibit low higher-order dispersion. They can, for example, exhibit near zero dispersion or some moderate relatively constant amount of GVD in the telecom C band. Such fibers, defined in ITU standard G.656 [1], are important not only for transmission fibers, but also e.g. for pulse compression, for signal processing using four-wave mixing and wavelength channel translation, and for the generation of broadband frequency combs.

Refractive Index Profile

Dispersion-flattened fibers achieve their performance through careful tailoring of their refractive index profile, which influences both material dispersion and waveguide dispersion.

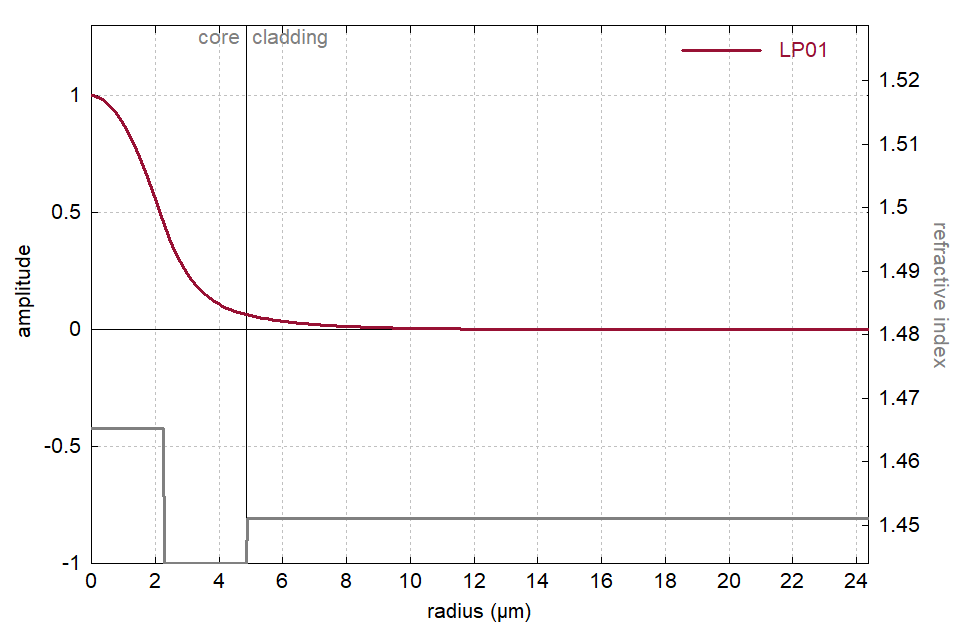

A typical DFF design features a W-shaped refractive-index profile, consisting of:

- a central core with slightly higher refractive index than the cladding

- a ring region of lower index surrounding the core (the inner cladding)

- an outer cladding with refractive index close to that of the base glass

Figure 1: Example of a W profile fiber design and the calculated mode amplitude profile. For details, see a case study for concrete examples of dispersion engineering of fibers.

This structure has several design parameters allowing fine control of the wavelength dependence of mode confinement: the relative core radius, the refractive index contrast, and the ring width.

Alternative designs may employ:

- multi-step or graded-index (e.g. triangular) profiles for finer control

- trench-assisted or dual-ring geometries for improved bend resistance and manufacturability

- photonic crystal fiber approaches for even broader flattening or for achieving dispersion control in nonstandard wavelength bands

The design process involves complex trade-offs among:

- dispersion flattening vs. effective mode area (which affects nonlinearities)

- guiding stability and single-mode operation

- splice loss and compatibility with standard SMF

- sensitivity to fabrication tolerances and refractive-index fluctuations

Achieving these balances requires precise control during fiber fabrication — especially in fiber preform fabrication, where deposition, doping concentration and geometry are crucial. Techniques such as modified chemical vapor deposition (MCVD), plasma chemical vapor deposition (PCVD) and outside vapor deposition (OVD) are often employed with stringent process control to maintain the designed profile.

See a case study for concrete examples of dispersion engineering of fibers:

Dispersion Engineering for Telecom Fibers

We explore different ways of optimizing refractive index profile for specific chromatic dispersion properties of telecom fibers, resulting in dispersion-shifted or dispersion-flattened fibers. This also involves automatic optimizations.

Frequently Asked Questions

What is a dispersion-flattened fiber?

A dispersion-flattened fiber is a type of dispersion-engineered fiber with a greatly reduced dispersion slope. This means its group velocity dispersion remains relatively constant over a specific wavelength range.

What is the advantage of dispersion-flattened over dispersion-shifted fibers?

While dispersion-shifted fibers shift the zero-dispersion wavelength, they still have a substantial dispersion slope. Dispersion-flattened fibers also reduce this slope, which is crucial for applications like wavelength division multiplexing where all channels should experience similar dispersion.

How is a flat dispersion profile achieved in a fiber?

Dispersion-flattened fibers have complex refractive index profiles, such as a W-shaped profile. This structure modifies the fiber's waveguide dispersion to counteract the wavelength dependence of the material's group velocity dispersion.

For which applications are dispersion-flattened fibers used?

Suppliers

Bibliography

(Suggest additional literature!)

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.