freeform optics (original) (raw)

Definition: optical elements with surfaces lacking rotational and translational symmetry about the optical axis

Alternative terms: free-form optics, non-rotationally symmetric optics

- optics

- geometrical optics

- wave optics

- Fourier optics

- quantum optics

- Gaussian optics

- technical optics

- aspheric optics

- adaptive optics

- diffractive optics

- integrated optics

- fiber optics

- flat optics

- micro-optics

- freeform optics

- laser optics

- nonlinear optics

- ultrafast optics

- infrared optics

- ultraviolet optics

- (more topics)

Related: opticsaspheric opticsoptical fabrication

Page views in 12 months: 141

DOI: 10.61835/4xp Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

📦 For purchasing freeform optics, use the RP Photonics Buyer's Guide — an expert-curated directory for finding all relevant suppliers, which also offers advanced purchasing assistance.

Contents

What Is Freeform Optics?

Freeform optics refers to optical components — for example, lenses and mirrors — whose surfaces (according to ISO standard 17450-1:2011) lack rotational and translational symmetry about the optical axis, described by complex, non-standard shapes.

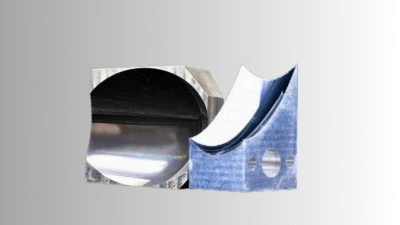

Figure 1: A freeform reflector. Source: Avantier.

Traditional optics essentially relied on flat and spherical surfaces only, which can be fabricated with simpler techniques. Aspheric optics were a first step to go for more general shapes; they generally stay rotationally symmetric, but more or less substantially deviate from a spherical shape, particularly at larger distances from the center. They are vital for minimizing optical aberrations (particularly spherical aberrations) in imaging systems. Freeform optics go further than that, altogether abandoning rotational and translational symmetry, which gives more freedom for optical design.

Description of Freeform Surfaces

Freeform surfaces can be described in various ways:

- A straightforward approach is to use higher-order polynomials in ($x$) and ($y$) (possibly also involving mixed terms ($x^n y^m$)) for the ($z$) elevation (sag) — either the total elevation or only a correction against a classical base profile, e.g. of spherical shape.

- Widely used in optics (see the article on optical aberrations), Zernike polynomials are orthogonal over the unit disk and are particularly well-suited for circular apertures. They can efficiently describe both symmetric and asymmetric aberrations, making them useful for freeform surface definition, especially when the aperture is round or nearly round.

- Various other polynomial forms are also employed, depending on the aperture shape and desired mathematical properties:

- Q-type polynomials are designed for improved numerical stability and slope continuity.

- Chebyshev polynomials are favorable for handling rectangular or non-circular apertures due to their defined orthogonality over rectangles and superior minimax properties.

- Legendre polynomials are another orthogonal set, also useful for rectangular domains.

The specific coefficients or parameters for the chosen mathematical expansion are typically determined through numerical optimization in optical design software. These tools iteratively adjust the parameters to achieve desired imaging, beam-shaping, or illumination properties, guided by numerical beam propagation or ray tracing simulations and performance metrics for image quality or light distribution.

Advantages Obtained with Freeform Optics

The central advantages of freeform optics are the following:

- They enable improved optical performance, e.g. better imaging quality, by reducing optical aberrations.

- They give more flexibility, e.g. for generating customized intensity distributions.

- They often help to work with a reduced component count, setup complexity and size. This is essentially because aberrations can easily be eliminated at a single freeform optical element, rather than with a sophisticated combination of elements for mutual canceling of certain aberrations.

For many applications (see below), these advantages more than compensate the additional cost of more complex fabrication of freeform optical components.

Fabrication of Freeform Optics

Freeform optics can be made from conventional optical glasses, various plastics, metals, or crystalline materials such as calcium fluoride, including semiconductors like germanium and silicon for infrared and specialized applications. Fabrication requires advanced manufacturing technologies, as traditional grinding and polishing methods are not suitable for irregular, non-rotationally symmetric surface geometries. Typically used techniques include the following:

- CNC machining: Multi-axis computer numerical control (CNC) machines with diamond tooling are widely used for shaping the optical surface according to a mathematically defined profile. This generation process provides a rough draft, which then undergoes further refinement.

- Grinding: Optical rough and fine grinding techniques are common for substantially improving the surface quality, e.g. of optical glasses.

- Diamond turning: Ultra-precise single-point diamond turning is often used for metals and certain crystals, enabling deterministic shaping at sub-micron tolerances.

- Subaperture polishing: Following grinding and diamond turning, subaperture polishing processes further improve surface smoothness and reduce form errors.

- Molding: For high-volume production, particularly with plastics, precision injection molding may be used, often relying on diamond-turned mold inserts.

- 3D printing: Emerging precision 3D printing methods also enable rapid prototyping and fabrication of freeform optical elements for some polymeric materials.

- Selective laser etching: This relatively new technique is an interesting alternative for fabricating very tiny freeform optics inside a glass block.

Sophisticated non-contact optical metrology generally needs to be performed during fabrication to ensure the complex surface meets design tolerances. One may use interferometry, optical profilometers, computer-generated holography and other methods.

Generally, fabrication of freeform optics is more expensive, but there are cases (e.g. when using molding techniques) where the cost difference may not be substantial.

Applications of Freeform Optics

Freeform optics excel in applications demanding higher performance, system compactness, or new optical functionalities not feasible with more conventional surfaces. Key uses include:

Imaging

Imaging systems represent one of the most transformative application areas for freeform optics. The versatility of freeform surfaces — unconstrained by rotational symmetry — opens the way for completely revised design strategies, enabling advanced functions, miniaturization, and unmatched performance improvements:

Aberration Correction and Image Quality

Freeform surfaces provide degrees of freedom that allow for the precise correction of optical aberrations — including coma, astigmatism, and field curvature — across the entire image plane. This capability leads to significantly sharper images, improved contrast, and higher spatial resolution, particularly in systems with demanding requirements or non-traditional geometries.

Wide Field-of-View and Off-Axis Imaging

In panoramic or off-axis systems — where imaging must occur far from the optical axis — classical rotationally symmetric optics often introduce intolerable aberrations. Freeform optics, by contrast, enable wide-field imaging with minimal distortion, making them essential in aerial/satellite cameras, panoramic surveillance, automotive surround-view systems and scientific instruments. Space-based telescopes and Earth-observation satellites extensively leverage freeform mirrors to capture wide swaths of terrain or sky in a single pass, maximizing field coverage and reducing the time or number of exposures needed.

Efficient Light Collection

For low-light imaging (e.g. for night vision devices), efficient light collection is essential.

In conventional, rotationally symmetric optical systems, aperture size often must be restricted, as larger apertures generally introduce significant optical aberrations — coma, astigmatism, field curvature — which degrade image quality, particularly away from the optical axis.

Freeform optical surfaces add essential extra degrees of freedom to the optical design. This enables correction of complex aberrations for each field point individually, even in systems with large, highly off-axis apertures. Consequently, freeform optics permit the use of much larger apertures — maximizing light collection efficiency without sacrificing image quality.

System Miniaturization and Integration

In traditional optics, aberrations are generally compensated by arranging optical components such that their aberrations largely cancel each other. That approach often requires a substantially increased component count.

Freeform imaging avoids that through the ability to combine multiple optical functions, going well beyond aspheric optics. Focusing, field flattening, and beam steering can all be accomplished with a single freeform surface. This consolidation yields substantial mass and volume savings. It also increases system reliability, as there are fewer surfaces and alignments that can introduce errors or degrade over time, and the more compact housing can be made more robust.

As a result, smartphone cameras and other portable imaging devices employ freeform elements to maintain high image quality while pushing thinner and lighter form factors. In wearable and embedded imaging systems, freeform optics are key to integrating powerful optics in restricted volumes.

Freeform mirrors and lenses are also prevalent in compact satellite imagers, instrumentation for planetary exploration, and lightweight drone cameras.

Custom Mapping and Distortion Control

Certain applications require customized image-to-sensor mapping, such as head-up displays (HUDs), augmented/virtual reality (AR/VR) headsets, or automotive side-view mirrors. Here, freeform optics implement tailored nonlinear magnification and perspective correction across the field, providing naturalistic views, eliminating blind spots, or expanding user comfort zones — functions which would be impossible to achieve with conventional lenses or mirrors, at least in compact form.

Displays

Freeform optics play a pivotal role in the design and advancement of modern display technologies, especially in head-up displays (HUDs) and augmented reality (AR) headsets:

Head-Up Displays (HUDs)

In automotive and aviation HUDs, freeform optics are used to project images directly into the user’s field of view, overlaying information such as speed or navigation onto the real-world scene. The core challenges here are:

- Off-axis imaging: HUDs typically must generate a virtual image at an eye-friendly distance while being physically located below or away from the line of sight. This requires the projection of light along complex, off-axis optical paths, leading to aberrations that only freeform surfaces can effectively correct.

- Curved windscreen compensation: In vehicles, the windscreen introduces distortions which the projector optics need to pre-compensate. This must work well for a range of viewing angles.

- Compact integration: With space constraints in dashboards and cockpits, freeform optics enable highly folded light paths for compact setups.

Augmented Reality (AR) Headsets and Smart Glasses

In AR systems, freeform optics are fundamental for both imaging and light routing:

- Waveguides and freeform combiners: Modern AR displays often use freeform prisms or waveguides with non-symmetric surfaces to steer, expand, and couple display light into the eye at precise angles. This supports wide fields of view, large eye-boxes (comfortable viewing regions), and compact, lightweight designs suited for wearable use.

- Optical see-through elements: Freeform surfaces are used to simultaneously present virtual images and pass through real-world light undistorted, allowing seamless overlay without color fringes, double images, or parallax errors.

Tailored freeform elements need to correct for lens distortions, alignment errors, and refraction introduced by the human eye or complex headset layouts, contributing to image sharpness and user comfort.

Some display systems incorporate MEMS-based micromirror arrays or other reflective devices. Freeform mirrors efficiently manage the off-axis ray bundles created by these devices, ensuring efficient light collection and delivery to the user’s eye, minimizing stray light, and supporting compact, folded optical architectures.

Sensing

Various optoelectronic sensors can benefit from freeform components, particularly where optical setups need to be kept very compact, or where one uses high aspect ratio sensors. Possible application areas are in automotive technology, security (occupancy and gesture detection), environmental sensing (e.g. weather and air quality, LIDAR) and medical diagnostics.

Beam Shaping

Tailored surfaces enable precise shaping of laser beam profiles, e.g. for scientific, industrial, and medical purposes. For example, one often needs to reshape asymmetric beam profiles, where optical elements with rotational symmetry are insufficient, or one would e.g. need to combine cylindrical lenses where each one works only in one direction.

Illumination

Freeform optics can produce custom intensity distributions for illumination. For example, they enable uniform illumination even with challenging geometries such as in biomedical endoscopes, or achieve precise control of light in automotive headlights and projectors.

In this field, the accuracy requirements are often substantially lower than in imaging applications.

Emerging Applications

With the rapid expansion of computational imaging, machine vision and sensor fusion, freeform optics are crucial for enabling hybrid optical/digital systems. Their role in tailoring point spread functions, encoding spatial information, or managing multi-aperture architectures is opening entirely new possibilities in 3D imaging, environmental monitoring, and autonomous vehicle perception.

Frequently Asked Questions

This FAQ section was generated with AI based on the article content and has been reviewed by the article’s author (RP).

What are freeform optics?

Freeform optics are optical components, such as lenses and mirrors, whose surfaces lack rotational and translational symmetry. Their complex, non-standard shapes offer more design freedom than traditional spherical or aspheric optics.

How do freeform optics differ from aspheric optics?

While aspheric optics deviate from a spherical shape but typically remain rotationally symmetric, freeform optics abandon rotational symmetry altogether. This provides much greater flexibility for correcting complex optical aberrations.

What are the main advantages of using freeform optics?

The key advantages are improved optical performance through superior aberration correction, the ability to create custom light distributions, and the potential to reduce the number of components, leading to more compact and lightweight systems.

How are freeform optics manufactured?

Their complex shapes require advanced techniques like multi-axis CNC machining, single-point diamond turning, and subaperture polishing. For high-volume production, precision molding is often used, while 3D printing is an emerging option.

Where are freeform optics used in imaging systems?

In imaging, they correct complex aberrations in wide-field-of-view and off-axis systems, such as satellite and surveillance cameras. They also enable miniaturization in devices like smartphone cameras and lightweight drone cameras.

Why are freeform optics essential for AR/VR displays and HUDs?

For augmented/virtual reality headsets and head-up displays, freeform optics manage complex, off-axis light paths to project clear virtual images. They enable compact designs, wide fields of view, and compensation for distortions from windscreens.

What materials are used for freeform optics?

Freeform optics can be made from conventional optical glasses, plastics, metals, and crystalline materials. This includes semiconductors like germanium and silicon for infrared applications.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 21 suppliers for freeform optics. Among them:

⚙ hardware

LightForge™ is a low-cost rapid fabrication service giving optical designers the ability to create innovative new freeform surfaces, test new ideas and verify designs for production without incurring expensive upfront engineering charges and lengthy prototyping lead times. LightForge™ can be used to create a wide range of refractive optical elements, from beam transformers and microlens arrays, to unique components such as diode laser smile correctors and wavefront compensator phaseplates, to completely custom surface shapes.

⚙ hardware

At Avantier, we produce custom freeform optics for cutting-edge applications in industry, defense, research, and medicine. We specialize in custom freeform optics design and manufacturing solutions for imaging, catering to single prototypes and bulk production alike.

A freeform optic is defined as one that has at least one surface with no translational or rotational symmetry about any axes that are normal to the mean plane. In practice, this means that freeform systems may be free from any constraints of symmetry.

Manufacturing processes:

- Unique challenges due to non-rotational symmetry.

- Utilizes state-of-the-art CNC optical grinding technology.

- Begins with roughing out the surface using CNC technology and diamond turning.

- Involves rough and fine grinding followed by sub-aperture polishing.

- Rigorous metrology checks ensure compliance with standards.

- Substrate options include metal, plastic, and various optical materials like germanium, calcium fluoride, etc.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

general optics

general optics