RD-0210/0211 engine (original) (raw)

RD-0210/0211 engine

Developed at the KB Khimavtomatiki, KBKhA, design bureau in the city of Voronezh, the RD-0210/0211 engine propels the second stage of the Proton rocket.

Previous chapter: Second stage of Proton rocket

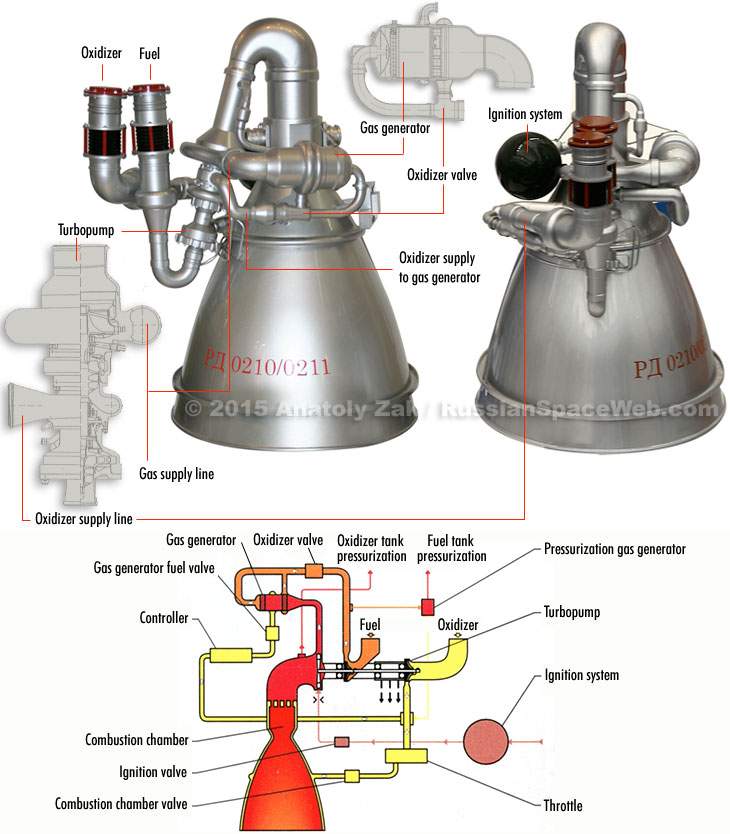

General design of the RD-0210/0211 engine.

From the publisher: Pace of our development depends primarily on the level of support from our readers!

RD-0210/0211 design

The second stage of the Proton rocket is currently equipped with four identical engines, however three of them are designated RD-0210 and one is dubbed RD-0211, because it differs from its cousins by additional hardware used for the pressurization of tanks onboard the second stage, to ensure the supply of propellant into the propulsion system during the flight. Similar hardware is used on the RD-253 engine on the Proton's first stage.

All four of Proton's second stage's engines can gimbal up to 3.25 degrees from their vertical position with the help of an electro-hydraulic system, so the rocket can be steered in flight on commands from the onboard computer.

The RD-0210/0211 engines feature a so-called closed-cycle design, where oxidizer gas is used to drive the main turbine of the engine and then is directed to burn in the combustion chamber instead of being dropped overboard. Such a setup improves the efficiency of the propulsion system but adds complexity to the hardware.

As the first stage of the Proton rocket is about to separate during the launch, RD-0210/0211 is initiated with a pressurized gas stored in a special vessel. Once released, this gas gives an initial spin to the turbopump. (120)

Development history

Developed under the leadership of Valery Kozelkov, the propulsion system for the second stage of the Proton rocket was based on the heritage of the ill-fated UR-200 rocket. It derived from the RD-0205 engine, which propelled the second stage of the UR-200. RD-0205 was only the second operational Soviet closed-cycle engine, coming in the footsteps of a kerosene-burning propulsion system developed at Sergei Korolev's OKB-1 bureau. Thus, the most serious technical challenges of the design were resolved in the course of the RD-0205 development, which started in March 1961.

When the development of engines for the Proton rocket was commissioned in 1962, the RD-0205 from UR-200 became the basis for three engines on Proton: the RD-0208 and RD-0209 engines on the second stage and the RD-0212 on the third stage. During the switch from a two-stage Proton rocket to a three-stage version in 1966, the second-stage engines were renamed RD-0210 and RD-0211 respectively.

During their adaptation for the second and third stage of the Proton rocket, all engines received a number of common upgrades compared to their predecessor, the RD-0205:

- The fuel line received a membrane valve with a bypass line and a cutoff valve. It was designed to optimize the ignition of the engines under most conditions, while avoiding a dangerous increase in the turbopump rotor speed and guarantee that the gas generator would always start firing slightly ahead of the burning process in the combustion chamber;

- More effective injectors were installed at entrances into the propellant lines to improve the performance of the turbopumps;

- Ignition valves were moved toward the entrances into the pumps in order to reduce hydraulic shock in propellant lines and in low-pressure areas of the engine.

The so-called experimental and final tune-up tests, or ZDI, of the engines were completed by the end of 1966. In October and November of the same year, engines were test-fired as part of the bench tests of a fully assembled third stage. In March 1967, they flew on the Proton rocket with the first prototype of the L1 circumlunar spacecraft.

Practically immediately, from December 1966 to August 1967, as Proton was undergoing flight testing, the bureau conducted the first effort to improve the reliability of the engine, which became known as Variant P. Changes included:

- The introduction of thermal protection made of zirconium dioxide, ZrO2, on the internal surface of the combustion chamber;

- The strengthening of several components, including the turbine housing;

- The introduction of a gas generator with lower pressure fluctuations on oxidizer injectors in order to reduce the influence of high-frequency vibrations;

- Improvements to the oxidizer pump aimed to reduce cavitation effects;

- The introduction of destructive tests on a number of components during sampling tests in the engine batches;

- Testing of the engine for leaks with a mixture of air and helium.

In addition, tougher testing procedures now included live firing of two RD-0210 and RD-0211 engines out of each batch of six engines, instead of one of five previously.

The final tune-up test, ZDIs, for the Variant P engines started in April 1967 and inter-agency certification tests, MVI, were completed in August of the same year. The serial production of the engines was initiated at the Voronezh Mechanical Plant, VMZ, where it continues until this day. A team of engineers led by Yu. D. Gorokhov took the job of supervising the serial production of the engine, as well as continuous bench tests and actual flight use of the engines.

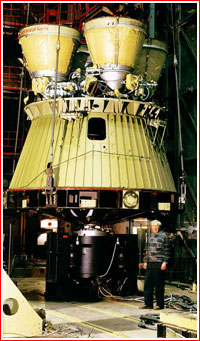

RD-0210 (top, left) carried by a crane during production at Voronezh Mechanical Plant circa 2016. RD-0212 engines can be seen on the background.

Operational use and technical challenges

Even before Proton started flying, engineers stumbled on a number of problems with the RD-0210/0211 system during ground tests of the engines. They were mostly associated with the ignition, the operation of the turbopump and high-frequency vibrations in the combustion chamber.

During the launch on Nov. 22, 1967, which carried an unmanned L1 spacecraft, one of the engines on the second stage failed to fire and the others reached their full thrust with a delay, leading to the complete failure of the launch. The investigation showed that the design of the engine did not account for the influence of the axial acceleration of the rocket on the process of filling the propellant lines during the ignition. After a series of calculations and ground tests, the ignition process was changed to account for the phenomenon.

In 1969, another failure of the RD-0210 engine took place, which was traced to the destruction of the ball bearing holding the shaft of the turbopump rotor. After several temporary measures to resolve the problem, a special mechanism designed to reduce loads on the rotor was added to the engine in 1982.

In 1978, another malfunction in the RD-0210/0211 engine led to a launch accident. Investigators determined that a component of the turbine had caught fire, supposedly as a result of the foreign particles getting into the system. The hypothesis was confirmed in a ground test in the same year. In 1999, two failures of the Proton rocket were again traced to the same problem. In the wake of these accidents, another series of upgrades was implemented in the design of the engine, as well as in its production and pre-launch processing procedures. (747)

(To be continued)

Specifications of the RD-0210/0211 engine:

| - | RD-0210/0211 |

|---|---|

| Thrust in vacuum | 593.6 kH (59.36 tons) |

| Specific impulse | 326.5 seconds |

| Combustion chamber pressure | 15 MPa (150 kilograms per square centimeter) |

| Absolute pressure at oxidizer injection | - |

| Absolute pressure at fuel injection | - |

| Propellant ratio | 2.6 |

| Thrust range | - |

| Burn time | 230 seconds |

| Dry mass | - kilograms |

| Engine length | 2,327 millimeters |

| Engine diameter | 1,470 millimeters |

| Prototype engine | RD-0206 from UR-200 ICBM |

Read much more about the history of the Russian space program in a richly illustrated, large-format glossy edition:

The article, graphics and photography by Anatoly Zak; Last update:April 2, 2018

Page editor: Alain Chabot; Last edit: June 28, 2015

All rights reserved

IMAGE ARCHIVE

Valery Kozelkov led the development of the RD-0210/0211 engine at KBKhA. Credit: Roskosmos

RD-0208 engine. Credit: KBKhA

RD-0210 engine. Credit: KBKhA

RD-0210/0211 propulsion system of the Proton rocket during assembly and testing. Credit: TsSNIIMash

A 1-to-5 scale models of the RD-0210/0211 engine (left) for the second stage and RD-0212 for the third stage of the Proton rocket (top and bottom right). Click to enlarge. Copyright © 2011 Anatoly Zak

)