Keeping Substations Shielded: Maintaining Proper Protection from Lightning (original) (raw)

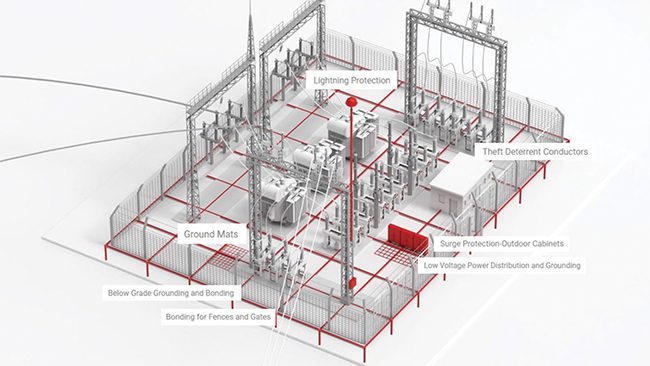

Electrical substations utilize direct lightning stroke shielding to help ensure proper operation, and to prevent costly damages and extended outages. While modern substation designs and equipment make them resilient to lightning strikes, the reality is that standard protective measures are sometimes inadequate against the destructive forces of this natural phenomenon.

Although lightning shielding systems cannot guarantee complete safety from strikes, the presence of a comprehensive solution for lightning and surge protection can dramatically reduce the effect of strikes on and near substations. To understand why a shielding system is needed, it is important to understand the risks.

|

|---|

| 1. All substation shielding, grounding, and bonding componentry should be compliant with applicable Institute of Electrical and Electronics Engineers (IEEE), as well as utility industry, codes and standards. Courtesy: nVent |

Substations (Figure 1)—having elevated structures, aerial wires, and filled with electrical equipment—are attractive targets for lightning strikes. Lightning creates incredibly powerful electric arcs up to and exceeding 200 kA that can heat nearby equipment including buses, switching gear, circuit breakers, transformers, and auxiliary equipment such as carrier-current capacitors to dangerous temperatures, leading to electrical fires.

Distance, meanwhile, is not the deterrent it may seem. Research shows that lightning strikes within a range of up to two miles (about 3,000 meters) are particularly dangerous to substations.

Damage and Outages

When lightning strikes it can damage equipment and instrumentation, disrupt service, and potentially cause injuries. While estimates vary, lightning strikes are generally considered responsible for up to 20% of all power outages in the U.S. each year, and cause more than $1 billion of property damage annually. In all cases, the potential financial losses stemming from severe transient events can be significant for utilities.

Utilities do have options when it comes to protecting substations. Passive lightning shielding systems are designed to protect a structure from a direct strike by providing a continuous path or discharge point for the current to the ground. They typically consist of masts, shield wires, and down conductors tied to a grounding system. Lightning arresters, or surge arresters, are also used. These do not permit electrical flow under normal conditions but can change properties in response to a strike, becoming conductors rather than insulators to redirect excess electrical energy.

Substations generally rely on passive shielding systems to manage the millions of added volts a strike can generate. While these systems can divert the current safely away from electrical equipment, they do not actively react to an impending lightning strike.

Active Shielding Systems

Active shielding systems respond faster to a strike. These tend to use sophisticated electronics and sensing equipment that monitor electrical fields locally. When a strike is incoming, the electric field changes and the system activates to capture the current by presenting a “preferred point” for discharge. Active systems (Figure 2) can provide higher levels of protection, and in some instances may be more cost-effective to install than passive systems as they eliminate the need for an array of steel shielding wires above the substation.

|

|---|

| 2. There are two main types of lightning shielding systems: active and passive. Active systems use unique features to attract and divert overcurrent. Passive systems instead rely on traditional air terminals and ground rods. Shown are two systems for capturing lightning energy, the nVent ERICO System 2000 providing conventional air terminal functionality, and the System 3000 that utilizes computer-aided design and electronic componentry. Courtesy: nVent |

Removing these overhead wires has a subsequent benefit to the utility, as in reality many of these are becoming aged and corroded and have the potential to fall into the station, causing even more damage and possible failures.

Power utilities looking for more effective lightning protection often find it with an active solution. Here, a single air terminal strategically placed on a substation can protect a large area without requiring shielding wires. Active protection can respond dynamically to the presence of lightning downward stepped leaders—the first indication of an approaching strike—and create charged-up streamers that attract the strike. This increases the probability that a strike inside the system’s area of protection will contact the system’s air terminal rather than the structure, and then be transferred safely into the grounding system.

How an Active Lightning Protection System Works

Figure 1 Figure 2 Figure 3

1. A rapid increase in the electric field occurs as the charged downward leader approaches. The air terminal (at left, here a floating dome) is connected to a down conductor and low-impedance grounding system, and provides a preferred point for discharge and collection.

2. The rate at which the dome will collect this charge and rise in voltage will be a function of the amount of charge in the approaching downward leader, and the rate of change in the electrical field (middle photo). Thus, the dome acts like a sensor to detect the magnitude and speed of the approaching leader.

3. The electrical circuit acts to control the voltage on the dome with this information, acting to either speed up or slow down the time it takes for the voltage on the dome to break down the spark gap between the dome and the center finial (at right). The timing of this breakdown (sparkover) is important. When the breakdown occurs, the dome will become grounded to the finial. This increases the electrical field directly above the air terminal, leading to an initiation of a strong upward leader.

Design Is Critical

Even with the right technologies, having a comprehensive lightning and surge protection plan is critical. Ultimately, it is a systematic approach to minimizing the threat of all types of electrical transients that affords the best protection for property and personnel. This means factoring for the potential for high-voltage spikes, ground faults, switching surges, electrostatic discharge, and other disruptions. Professional design assistance can help utilities achieve full substation protection.

nVent ERICO acknowledges that no single technology can totally eliminate vulnerability to lightning strikes and power surges. However, there are proactive measures that can be taken by utilities to help ensure asset reliability that integrate solutions for lightning protection (LP), surge protection, and grounding and bonding that are all interdependent disciplines.

Professional designers can build three-dimensional models of lightning protection systems (LPSs) that help to determine exactly where to place air terminals and down conductors. The nVent ERICO lightning protection system brings together design consultation utilizing advanced software for accurate terminal layout and modeling. An engineering team, focused on executing best practices for electrical equipment protection, applies electro geometric modeling (EGM) analysis to any lightning protection design methodology in accordance with Institute of Electrical and Electronics Engineers (IEEE) 998 guidance (“Direct Lightning Stroke Shielding of Substations”) and other global standards.

EGM analysis can more effectively determine zones of protection for lightning shielding solutions. Substation LP shielding systems are typically designed to protect equipment for all lightning current levels greater than the flashover basic insulation level (BIL) of the substation bus systems and equipment.

Once designs have been completed, a coordinated strategy can be developed. This will account for capturing the lightning strike, conveying the energy to ground, dissipating the energy into the grounding system, bonding all ground points together, protecting incoming alternating current (AC) and direct current (DC) power feeders, and protecting low-voltage data/telecommunication circuits. This all-encompassing approach provides a checklist covering all damage mechanisms.

Importance of Materials

Additionally, utilities are cautioned that quality materials count in the design and installation of electrical protection solutions. Despite appearances, all products are not the same quality due to fundamental differences in materials of construction, components, installation methods, and certifications. Each product offers its own unique benefits, drawbacks, and levels of protection.

Materials of construction can vary in terms of resistance to corrosion, electromagnetic interference, and energy absorption levels, which can result in different levels of durability. Likewise, components such as surge protectors, ground rods, and bonding straps have different designs and qualities that affect the overall performance. The installation process is also critical, as different connections and locations can require different methods and materials.

It is imperative for utility companies to pay attention to quality control and proper screening of vendors in order to make sure they purchase products with maximum protection capabilities. Products of unknown origin may be less effective in shielding from strikes and surges, and may contain components that do not meet industry requirements.

Utilities are faced with the task of making sure new and aging grid infrastructure can stand up to new demands. Substations are too important to trust to inadequate or outdated lightning protection systems. Increasingly, active LPSs are helping to reduce the consequences of a strike.

Moreover, a comprehensive strategy against lightning strikes and power surges can add the reliability and resiliency that the future grid demands. Utilities are encouraged to seek the counsel of a lightning protection system specialist to explore an expanding array of possibilities.

—This article was contributed by the team at nVent ERICO, which provides protection solutions for structures, equipment, and people across several industries.