14 Types of Wood Drill Bits (Which to Use & Why) | Saws on Skates® (original) (raw)

Not sure which drill bit you need? I’m breaking down 14 types of wood-drilling bits and when to use them so you can select the best one for the job!

With so many drill bits out there, it can be overwhelming trying to decide which one you need for your project. I’ve got you covered with this guide to 14 bits frequently used for drilling holes in wood. We’ll look at their advantages, drawbacks, and uses so you’ll have all the knowledge necessary to select the right bit for your needs!

Table of Contents

- What is a Bit?

- What are Drill Bits Used For?

- What are the Parts of a Drill Bit?

- 14 Types of Drill Bits for Wood

This article contains affiliate links. If you purchase from these links, I may earn a small commission at no additional cost to you. Visit my site policies for more information.

What is a Bit?

Bits are accessories often used with tools such as drills, and they come in two varieties: driver bits and drill bits. Driver bits are designed for driving screws, while drill bits enable you to make holes in materials such as wood and metal.

This article will focus on bits for drilling holes in wood.

What are Drill Bits Used For?

Drill bits make holes in wood, metal, plastic, and other materials. They come in different types and sizes, but all contain a sharp edge to cut away material as the bit spins around.

In the case of wood, these types of bits can be used to make pilot holes, enlarge existing holes, countersinking screws, and more.

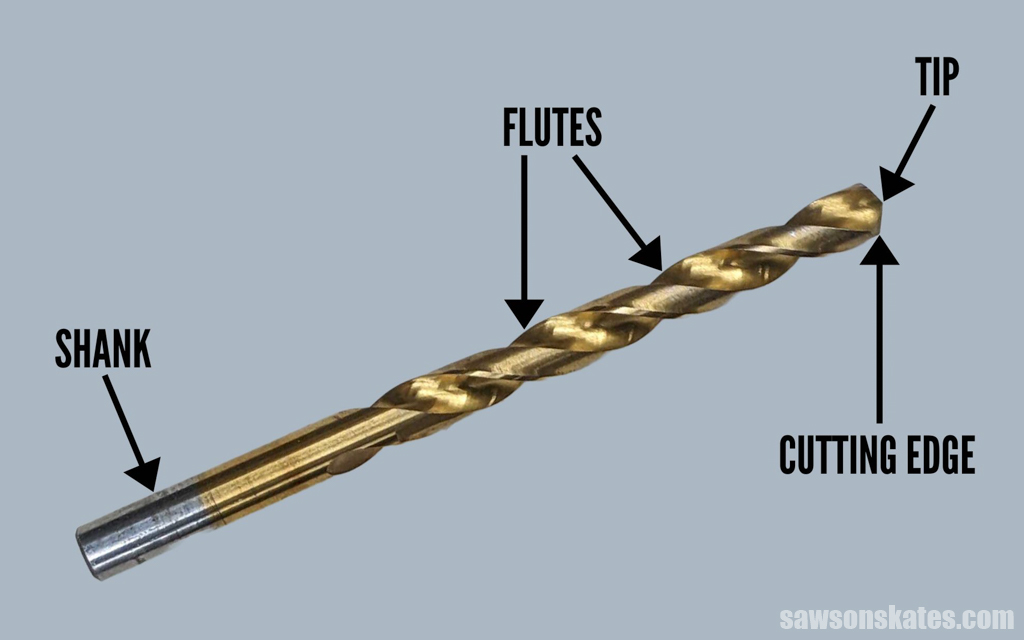

What are the Parts of a Drill Bit?

The parts of a drill bit vary depending by type, but most have a few common elements:

- Shank: The shank is the part of the bit that fits into a drill’s chuck, a clamp that holds the bit in place as it rotates. Drill bit shanks come in two common shapes: hexagonal and round.

- Tip: The tip or point is the sharp end of the bit and is usually angled to help guide it into the material.

- Cutting Edge: The cutting edge is the part of the bit that cuts away the material.

- Flutes: The flutes are spiral grooves along the length of a drill bit that help clear debris from the hole while drilling.

Now that we’ve covered the basics, let’s look at the types of drill bits for making holes in wood.

1. Twist Drill Bit

The twist drill bit or twist bit is the most common bit used for making holes in wood, and it’s what probably comes to mind when you think of a drill bit.

Twist bits have a cylindrical shape, a sharp point, two cutting edges, and two spiraling flutes that remove material from the hole as it turns.

They are usually made of high-speed steel and available with various coatings, such as titanium which adds strength, improves corrosion resistance, and reduces friction.

Twist bits are generally affordable and often bought in sets ranging in size from 1/16-inch to 1/2-inch, but smaller and larger bits are available, depending on the application.

The biggest advantage of a twist bit is its versatility. It can be used on various materials, including metal and plastic, and it’s the go-to choice for many woodworking projects..

I frequently use twist drill bits for making pilot holes and enlarging existing ones. A pilot hole, or pre-drilling, is a small hole drilled into a workpiece that creates an opening for a screw or a larger drill bit.

Related: How to Drill Pilot Holes (Why, When & Correct Size)

One potential risk of using twist bits is they can wander off course, also known as walking or skating. Wandering can damage the surface of your project and make a hole where it wasn’t intended. To prevent this problem, it’s a good idea to create a starting point with an awl before you begin drilling.

Related: What is an Awl? (+ How to Use It)

Pros:

- Versatile and can be used on various materials

- Generally affordable

- Available in a range of sizes

- Can be used to make pilot holes and enlarge existing ones

Cons:

- Can wander off course without a starting point

2. Spade Bit

A spade bit, sometimes called a paddle or flat bit, is designed for making large holes in wood.

Spade bits have a flat, paddle-like shape with two sharp cutting edges, allowing them to cut away material quickly.

You can purchase paddle bits individually or as a set. Typical sets often come with bits ranging from 1/4-inch to 1-inch. Spade bits are ideal for drilling holes up to 1-1/2 inches, but if you need a larger opening, consider switching to a tool such as a hole saw.

The advantage of spade bits is they can quickly make large holes; however, the holes they produce are rough with torn edges. For this reason, they are often used for construction projects where the hole won’t be seen; think of holes in wall studs to run electrical wiring or plumbing that will eventually be hidden by drywall.

Pros:

- Can quickly make large holes

- Available in a range of sizes

Cons:

- The holes they produce are rough, with torn edges

3. Brad Point Bit

Brad point bits are designed for drilling precise holes in wood. If you look closely, you’ll notice they look like a combination of a spade and twist bit featuring a pointed tip, two cutting edges, and usually two flutes.

The stand-out features of a brad point bit are its tip and cutters. The tip eliminates using an awl to create a starting point and reduces the risk of the bit walking, while the cutters make a crisp hole with smooth edges and minimal tearing.

Its pinpoint accuracy and clean results are ideal for making precise holes in both soft and hardwood.

Brad points can be more expensive than other bits, but if your project requires precision, such as drilling holes for dowel joinery, a brad point bit is an excellent choice.

Brad point bit sets include most common sizes, ranging from 1/8-inch to 1/2-inch; however, smaller and larger sizes are also available.

Pros:

- Produces clean, precise holes

- Doesn’t wander off course

- Can be used on soft and hardwood

Cons:

- More expensive compared to other drill bits

4. Pilot Point Bit

A pilot point bit is a variation of a twist bit, with a tip that makes its own pilot hole and cutting edges that efficiently bore a clean hole.

The pilot point tip is less likely to wander than a regular twist bit, but sometimes it’s tricky to get the tip perfectly positioned on your mark. To avoid a misaligned hole, I recommend using an awl beforehand to create a starting point for the bit.

Pilot point bits are excellent for drilling into metal and wood surfaces. They are available in sets ranging in sizes from 1/4-inch to 1/2-inch and beyond.

Pros:

- Makes its own pilot hole, reducing the risk of wandering

- Available in a range of sizes

Cons:

- Can be tricky to get the tip perfectly on your mark without a starting point

5. Auger Drill Bit

An auger bit is ideal for drilling deep holes with smooth edges in wood. Its screw-like tip keeps it on course and pulls the bit into the material.

At the end of an auger bit, two sharp points known as spurs score a circle identical in size to the hole you’re drilling. Two cutting edges cut away material within that circle, while spiral flutes help remove chips from the hole.

Auger bits are ideal for boring deep holes in thick pieces of wood, like posts, when constructing a deck or home building.

Auger bit sets range in size from 1/2-inch to 1-1/8 inches and beyond; however, larger bits require a more powerful drill.

Pros:

- Ideal for drilling deep holes with smooth edges

- Keeps on course and pulls the bit into the material

- Available in a range of sizes

Cons:

- Larger bits require a more powerful drill

6. Forstner Drill Bit

A Forstner bit performs a similar function as a spade bit, but it does so more precisely, producing a smooth-sided hole with a flat bottom.

Forstner bits are ideal for making clean-cut holes partially or entirely through wood, but what sets them apart from typical drill bits is their outer cutting edge guides them instead of the center tip.

Related: What is a Forstner Bit? (& How to Use It)

This unique feature, along with a drill press, allows them to drill partially overlapping holes, angled holes, and even holes on the edge of workpieces. These capabilities make them an excellent choice for doweling, mortising, and installing recessed hinges.

Forstner bit sets typically range in size from 1/4-inch to 2 inches.

Pros:

- Produces a smooth-sided hole with a flat bottom

- Able to drill partially overlapping holes, angled holes, and holes on the edge of workpieces

- Available in a range of sizes

Cons:

- Some operations require a drill press

- More expensive than other types of bits

7. Countersink Drill Bit

A countersink bit allows you to make a recess in wood so that the screw head sits flush with the surface. Not only does this prevent tearout and reduce splitting, but it also ensures the screw makes better contact with the material. On top of that, countersinking screws give your projects a much cleaner and more professional appearance.

Related: How to Use a Countersink Bit

When it comes to countersink drill bits, you have two options: a fluted bit and a combination bit.

A combination bit is a twist bit inside of a fluted bit that creates a pilot hole and a countersink hole in one step. On the other hand, making a countersink hole with a fluted bit requires two bits and two steps. First, you’ll drill a pilot hole with a twist bit and then use the fluted bit to make the countersink hole.

I reach for a countersink bit almost every time I need to drive a screw, especially if it will be visible on my finished project. It’s the perfect choice for an aesthetically pleasing, professional-looking result.

Pros:

- Prevents tearout and reduces splitting

- Ensures screws make better contact with material

- Gives projects a cleaner and more professional appearance

Cons:

- Requires two bits and two steps if using a fluted bit

8. Hole Saw

A hole saw, sometimes called a hole cutter, is a cylinder-shaped saw blade that cuts circular holes in materials such as wood.

Hole saws have two basic parts: a drill bit and a saw blade. The drill bit is a standard twist bit used to create the center pilot hole, while the saw blade has teeth around its circumference to cut the larger hole.

Hole cutter sets come in a range of sizes, from 3/4-inch up to 6-inches, and are ideal for making larger diameter holes like those needed for pipes, door knobs, recessed lighting fixtures, and even cornhole boards.

One drawback of hole saws is they tend to create a lot of tearout and wood chips on the back side of the material. You can reduce tearout by supporting the back side with a backer board or piece of scrap wood. Another option is drilling halfway through the workpiece, flipping it over, and then drilling the rest of the way through from the other side.

Pros:

- Ideal for making larger diameter holes

- Available in a range of sizes

Cons:

- Produces a lot of wood chips and tearout on the back side of the material

9. Self-Feeding Bit

A self-feeding bit works much like a Forstner bit but has a screw-like tip that guides the tool and pulls it into the material.

Like Forstner bits, self-feeding bits make smooth, flat-bottomed holes; however, they’re the better option when you need to create these types of holes at an angle. In contrast to a Forstner bit, the screw-like tip requires you to reverse your drill to remove the bit from the workpiece.

Pros:

- Ideal for creating smooth, flat-bottomed holes, especially at an angle

Cons:

- You must reverse the drill to remove the bit from the workpiece

10. Installer Bit

Installer bits, also known as bell hanger or fishing bits, are long drill bits essential for making holes through walls and other areas to run wires or cables.

These unique bits penetrate almost any obstruction in their path, from nails and steel plates to sheet metal. The bits also have wire-fishing holes on their body and shank, allowing you to pull wires or cables through the newly-drilled hole easily.

Some installer bits have a screw-like tip, preventing them from wandering when beginning to drill and eliminating the need to create a starting point for the bit.

Pros:

- Able to penetrate almost any obstruction in its path

- Fishing holes enable easy pulling of wires or cables through walls

- Screw-like tip prevents bit wandering when drilling

Cons:

- None really. Installer bits are an excellent bit for running wires or cables through walls

11. Step Drill Bit

Step drill bits, also called unibits, are designed to make a range of hole sizes in one operation without the need to change bits.

These drill bits feature stepped cones with cutting edges that form holes when you feed the bit into the material.

Step drill bits come in various sizes and are primarily used for making holes in thin metal, but you can also use them to drill holes in plywood.

Pros:

- Ideal for drilling a range of hole sizes without changing bits

Cons:

- Primarily used for thin metal, but can be used for wood

12. Plug Cutter

A plug cutter is used to cut wooden plugs to conceal screw holes or disguise blemishes in your woodworking projects.

Plug cutters feature sharp edges that cut a cylindrical plug when fed into a workpiece. The plugs can then be glued and tapped into place to hide screw holes or other imperfections.

Plug cutter bits come in various sizes, typically from 1/4-inch to 5/8-inches.

Making plugs requires precision and accuracy, so it is essential to use a drill press rather than a handheld drill for the best results.

Pros:

- Ideal for hiding screw holes and blemishes in woodworking projects

Cons:

- Must use a drill press for the best results

13. Pocket Hole Drill Bit

Pocket hole drill bits are essential for pocket hole joinery, a quick and easy method for joining wood.

Related: Which Pocket Hole Jig Should You Buy? (Here’s the Answer)

Pocket hole drill bits have a unique stepped design, with the tip forming an opening for the pocket screw to pass through, the shoulder creating a flat surface for the screw’s head to seat against, and the cutting edges creating the recessed area of the pocket hole.

Pocket hole drill bits require a pocket hole jig to make the holes at a precise angle. Though you can use them with a cordless drill, I feel holes made with a corded drill have smoother edges with less tearout. If you’re going to use a cordless drill, make sure the battery is fully charged.

Related: 9 Pocket Hole Mistakes You Don’t Want to Make

Pros:

- Ideal for quick and easy joinery in woodworking projects

Cons:

- Requires a pocket hole jig to drill holes at the correct angle, and best results are achieved with a corded drill.

14. Self-Centering Drill Bit

Need a quick, easy solution to make holes for door hinges? Look no further than self-centering drill bits. Also known as hinge bits, these tools feature a twist bit surrounded by a cylinder-shaped spring-loaded mechanism.

The tip of the cylinder fits into the countersunk recesses of hardware such as hinges, strike plates, and more. When you press on the bit, the spring-loaded mechanism retracts, allowing you to drill a perfectly centered hole.

You can also use self-centering bits for making pilot holes; however, they are typically available in limited sizes and are generally more expensive than a comparable twist bit.

Pros:

- Ideal for quickly and accurately drilling holes in door hinges, strike plates, and more

Cons:

- More expensive than a twist bit and only available in a limited range of sizes

Which Type of Drill Bit Should I Buy?

The type of drill bit you need will depend on your project. This comprehensive guide should help you make an informed decision when choosing the right bit for your specific needs.

If you’re just getting started in woodworking, I recommend investing in a basic set of twist bits that should cover your needs for many projects. When tackling more complex projects requiring specialty bits, you can purchase them as needed.

Final Thoughts

Many types of drill bits are available, each designed for a specific purpose. Understanding the basics of each type will help you make an informed decision when choosing the right bit for your DIY projects.

Thank you for stopping by. If you enjoyed this tutorial, would you please take a moment and pin it to Pinterest? I’d really appreciate it!

Pin This For Later