The effect of ultraviolet light on the mechanical properties of polyethylene and polypropylene films (original) (raw)

Abstract

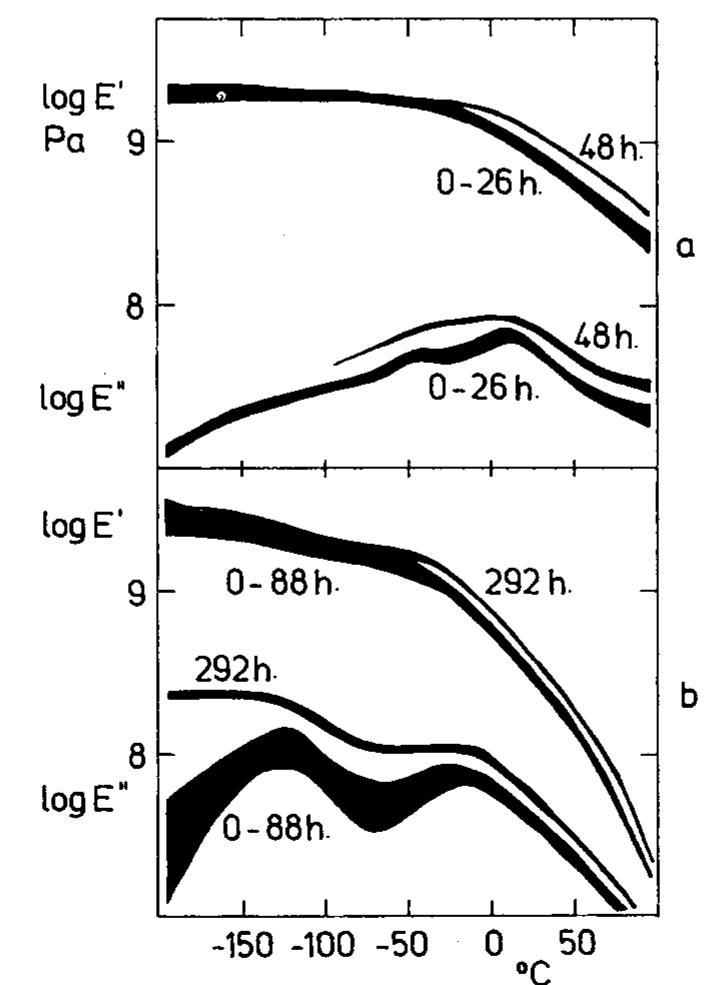

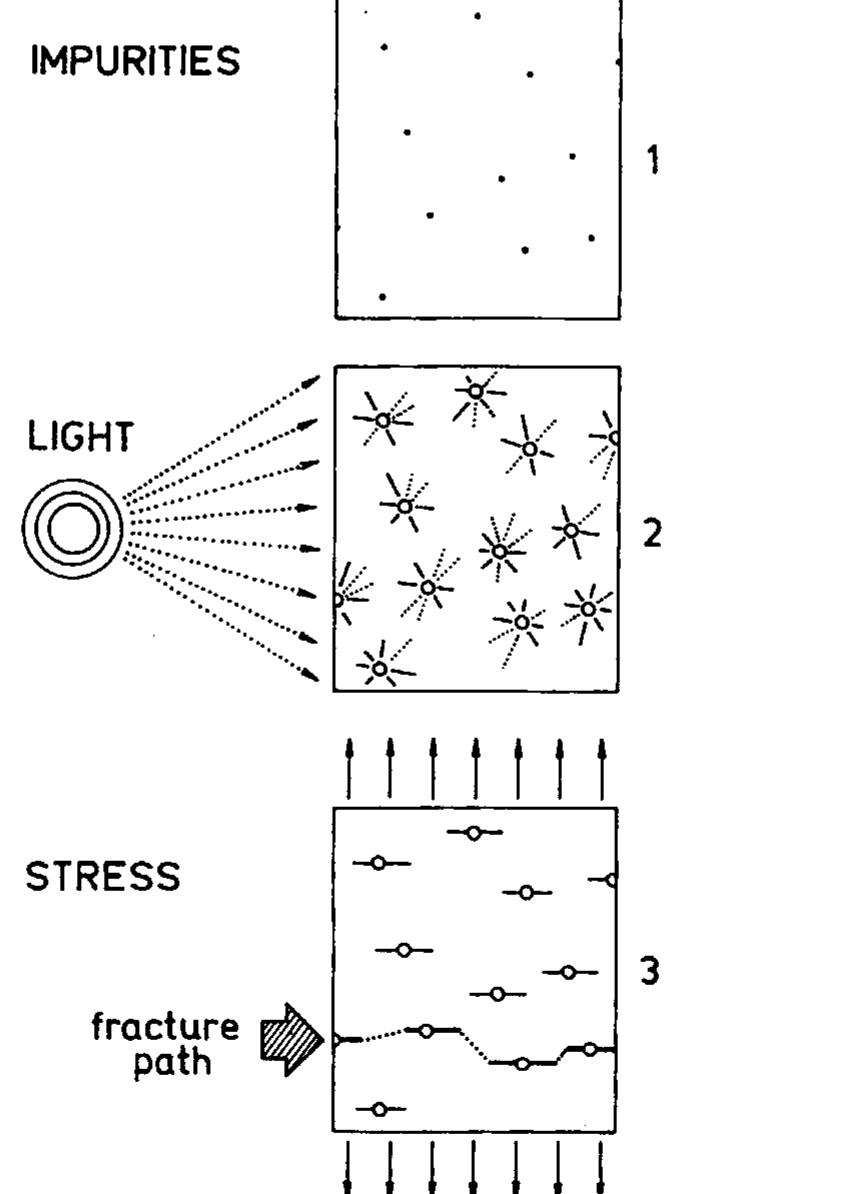

Measurements were made of dynamic mechanical response spectra and stress-strain properties at room temperature on films of isotactic polypropylene and low-density polyethylene prior and after ultraviolet irradiation in a Xenotest 450 apparatus. The period of irradiation that caused a deep deterioration of ultimate mechanical properties influenced the dynamic mechanical properties only insignificantly. This is attributed to the heterogeneous nature of the photo-oxidative degradation process which is concentrated in a finite number of sites, thus forming crack precursors rather than changing the material properties in bulk. For a biaxially oriented tubular film of low-density polyethylene, anisotropic embrittlement after exposure in Xenotest 450 was observed. This even reversed the order of strain-at-break values in the two main directions of the film. This is remarkably similar to the effect of artificial incisions introduced into the specimens.

Figures (8)

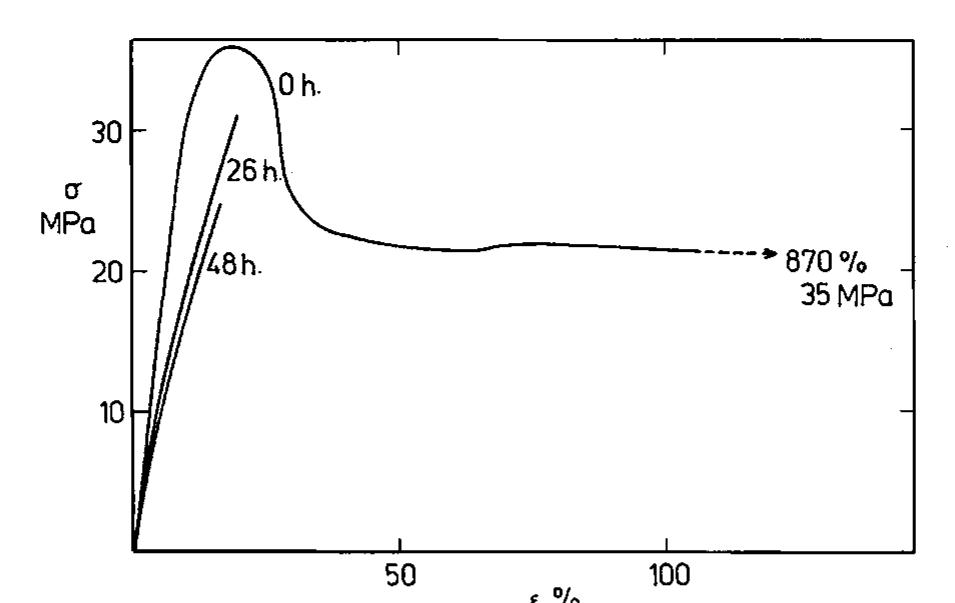

Fig. 2. Effect of UV exposure on stress-strain curves of isotropic film of isotactic polypropylene at room temperature. Numbers at curves indicate irradiation time (h).

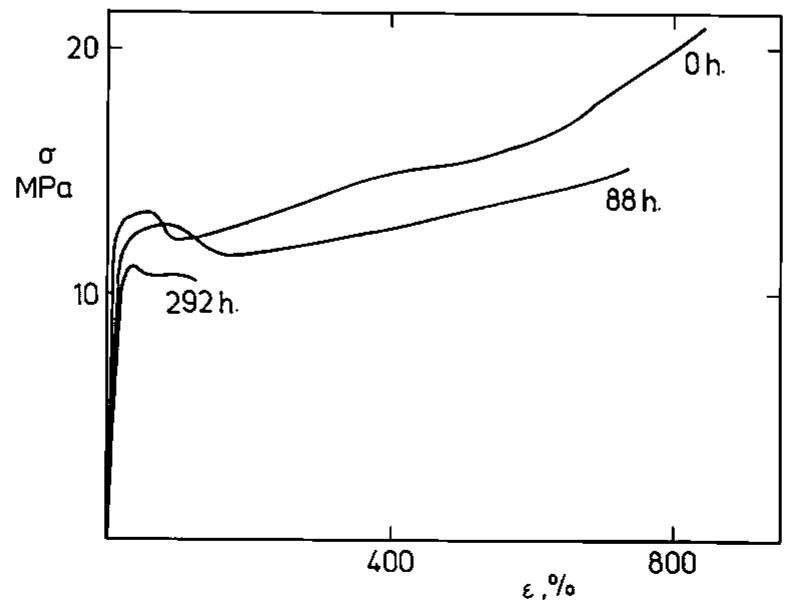

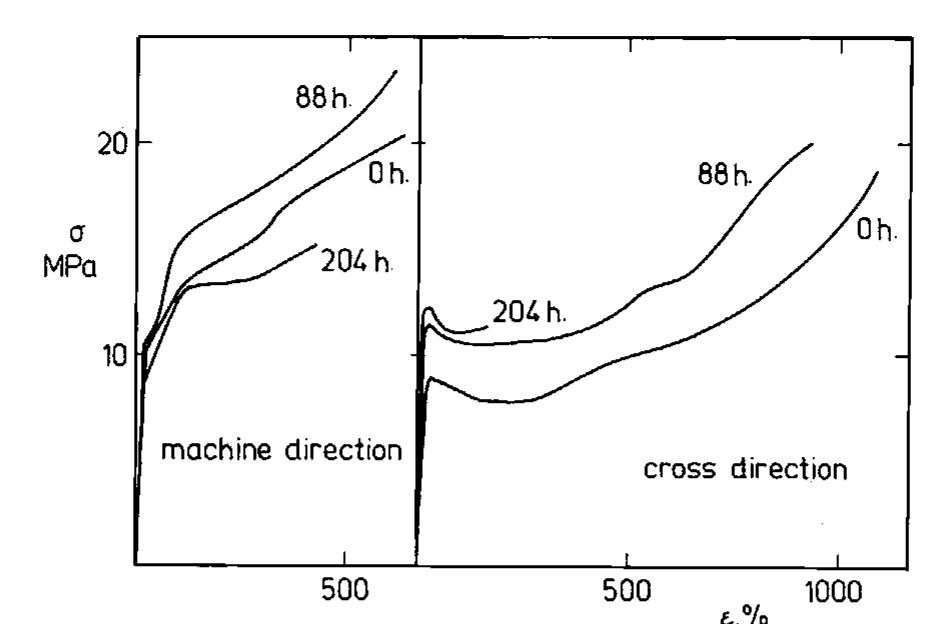

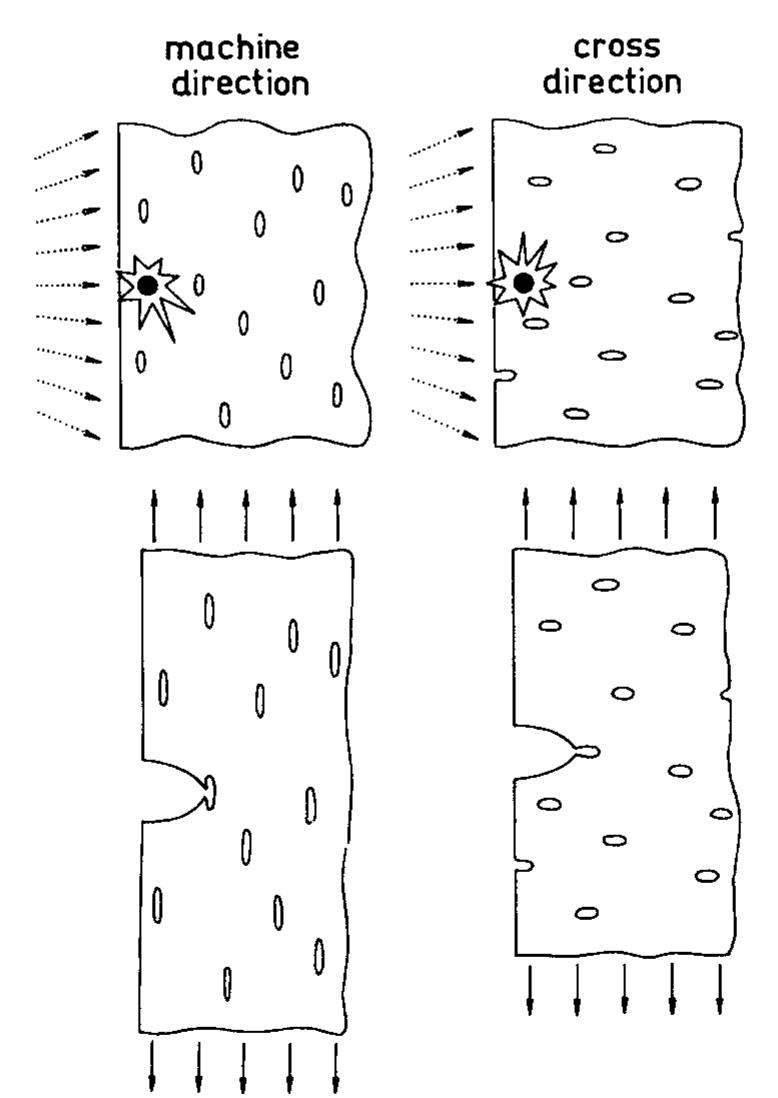

4 MPa for exposure times of 26 and 48 h, respectively. There are two reasons for the sensitivity of the ultimate properties in photo- xidative degradation. One is the key role of defects or cracks in the fracture ehavior of materials already expressed theoretically in the classical Griffith oncept and in the statistical weakest link hypothesis. Another reason is the eterogeneous character of the degradation process itself. One should bear in rind that photodegradation proceeds preferentially in a comparatively localized 2gion near the initiation site (such as, e.g., photosensitive impurity, a structural lement in the polymer or additive). Such a localization of the process is a onsequence of the low molecular mobility both of the polymer and of the pho- yactive site in the solid state. Chemical reasons are also involved here, e.g., the ip mechanism of degradation along the polymer chain. The probability of the ccurrence of these degradation sites is higher in the surface layer of the body, 1 particular in the case of polypropylene, but such sites may also lie inside the ulk of the material.’ When the body is subjected to mechanical stress, the Fig. 3. Effect of UV exposure on stress-strain curves of anisotropic blown film of low-density polyethylene at room temperature. Numbers at curves indicate irradiation time (h).

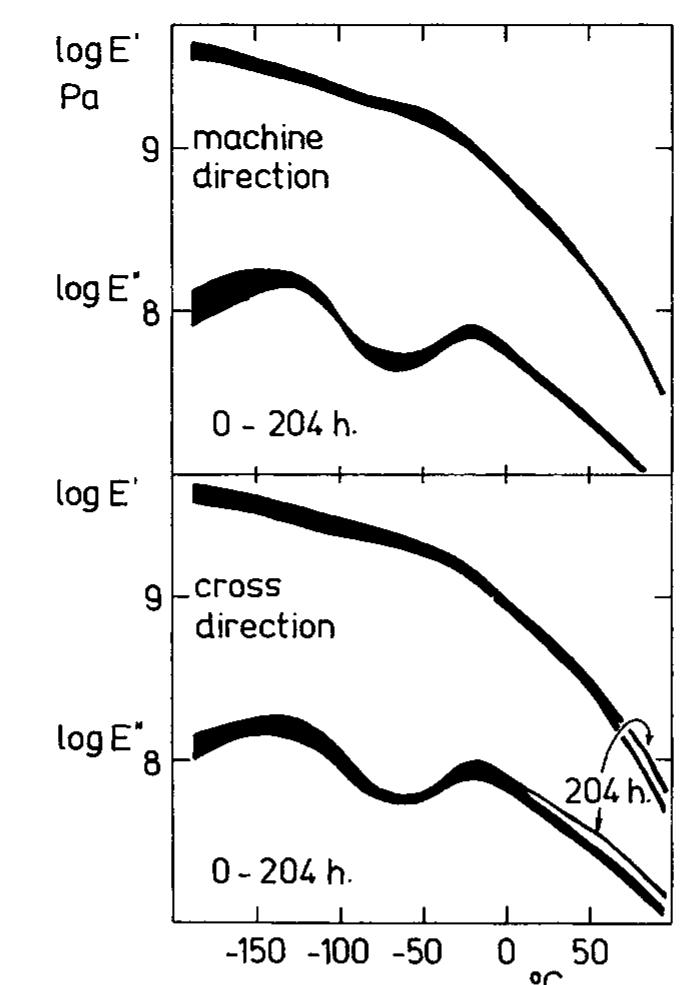

contrary to the conclusions of Ref. 11, the values of both components of the complex Young’s modulus are somewhat higher in the cross direction than in the machine direction. Although such a behavior is reproducible in the film under investigation, its structural interpretation still remains somewhat unclear. Similarly to the case of isotropic films, two characteristic loss maxima, 8 and y, can be seen on the loss modulus vs. temperature dependence curve. As the maximal irradiation time used for tubular film (204 h) was shorter than that for isotropic film, changes in the dynamic mechanical characteristics of degraded samples do not distinctly exceed the limits of experimental scatter. (The small shift of the experimental curves toward lower values of the moduli in the lower-temperature range cannot be regarded as significant.) The stress—strain curves of a biaxiallv oriented unstabilized film before and

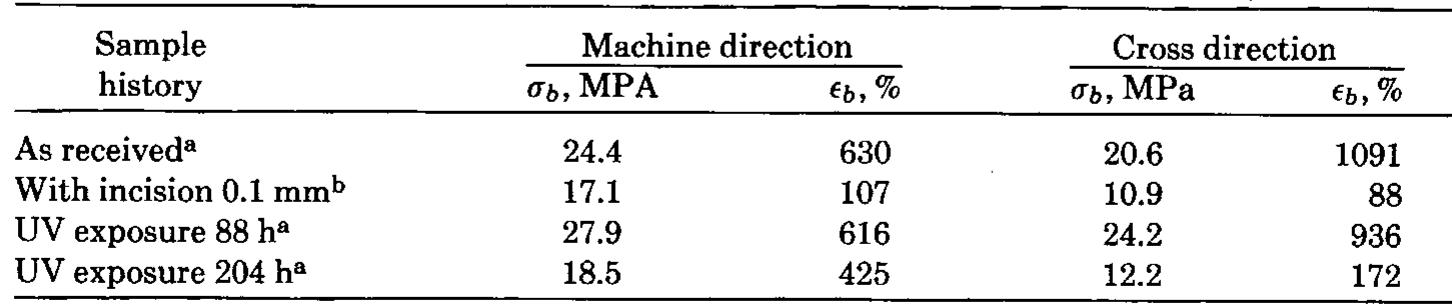

Tensile Strength o, and Strain at Break ey of Biaxially Oriented Blown Polyethylene Film @ Specimen width 5 mm, gauge length 12.5 mm. b Specimen width 10 mm, gauge length 25 mm. TABLE I

Fig. 6. Effect of UV exposure on stress-strain curves of a biaxially oriented blown film of low- density polyethylene at room temperature. Left: test pieces cut out along the machine direction; right: test pieces cut out in the cross direction. Numbers at curves indicate irradiation time (h).

WIth tnat or iocahzed photodegradation to create a unlorm structure. However, alternatively to the above explanation based on anisometric voids it is possible to consider the crack growth from isometric voids into an anisotropic material under uniaxial stress. Besides, Akay, Tincer, and Aydin® report that the increasing degree of orientation (draw ratio) slows down the kinetics ot! photo-oxidative degradation in the bulk of the material as reflected by the car- bonyl index. It is known that extremely oriented polyethylene exhibits an ex: traordinarily good resistance to photodegradation. In spite of this, the result: reported by Akay et al.8 were obtained at an irradiation time longer by an orde1 of magnitude than those used in this study. The carbonyl index method em. ployed by them does not indicate any pronounced differences between sample: oriented to various degrees up to 200 h of irradiation time. Thus, the volume and the localized effects of orientation on the degradation kinetics do not rule each other out, and both effects may even act simultaneously within a certair time interval. Fa, a, |); , ne ie Cs a ne k,n Fi a ee” oe cae Ce: ae heey Lm

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

References (14)

- J. W. S. Hearle and B. Lomas, J. Appl. Polym. Sci., 21,1103 (1977).

- B. Wnby and J. F. Rabek, Photodegradation, Photo-Oxidation, and Photostabilization of

- J. Pabiot and J. Verdu, Polym. Eng. Sci., 21,32 (1981).

- B. Mnby and J. F. Rabek, J. Appl. Polym. Sci. Appl. Polym. Symp., 35,243 (1979).

- D. Gilead, Znt. J. Polym. Mat., 6,185 (1978).

- A. Ram, T. Meir, and J. Miltz, Znt. J. Polym. Mat., 8,323 (1980).

- P. Vink, J. Appl. Polym. Sci. Appl. Polym. Symp., 35,265 (1979).

- G. Akay, T. Tincer, and E. Aydin, Eur. Polym. J., 16,597 (1980).

- N. G. McCrum, B. E. Read, and G. Williams, Anelastic and Dielectric Effects in Polymeric Polymers, Wiley, London, 1975. a Solids, Wiley, London, 1977.

- G. Akay, T. Tincer, and H. E. Ergoz, Eur. Polym. J. 16,601 (1980).

- W. P. Leung, C. C. Chan, F. C. Chern, and C. L. Choy, Polymer, 21,1148 (1980).

- M. Raab and G. Zamfirova-Ivanova, J. Appl. Polym. Sci., to appear.

- M. Raab and G. Ivanova, Int. J. Fracture, 15, R107 (1979).

- G. Zamfirova-Ivanova, M. Raab, and Z. Pelzbauer, J. Mat. Sci., 16,3381 (1981).