Slow crack growth: Models and experiments (original) (raw)

Abstract

The properties of slow crack growth in brittle materials are analyzed both theoretically and experimentally. We propose a model based on a thermally activated rupture process. Considering a 2D spring network submitted to an external load and to thermal noise, we show that a preexisting crack in the network may slowly grow because of stress fluctuations. An analytical solution is found for the evolution of the crack length as a function of time, the time to rupture and the statistics of the crack jumps. These theoretical predictions are verified by studying experimentally the subcritical growth of a single crack in thin sheets of paper. A good agreement between the theoretical predictions and the experimental results is found. In particular, our model suggests that the statistical stress fluctuations trigger rupture events at a nanometric scale corresponding to the diameter of cellulose microfibrils.

Key takeaways

AI

- Statistical stress fluctuations trigger slow crack growth in brittle materials, as evidenced by experiments on paper.

- The model predicts crack length evolution based on thermally activated processes, with lifetime τ and growth length ζ as key parameters.

- Experimental results show critical stress intensity factor Kc = 6±0.5 MPa.m1/2, indicating the material's brittleness.

- Crack growth dynamics are characterized by intermittent jumps and periods of rest, demonstrating complex behavior.

- The activation volume V, related to cellulose microfibrils, is crucial for predicting rupture events at a nanometric scale.

Figures (15)

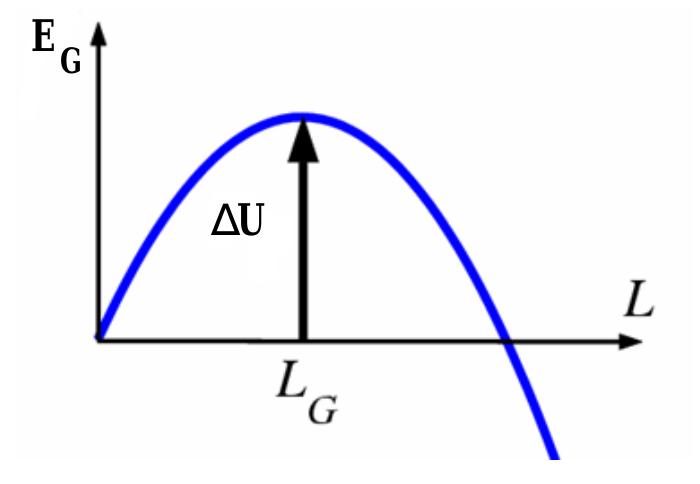

Figure 1: Sketch of the Griffith potential energy Eg as a function of crack length LD.

[

Figure 2: Sketch of the Griffith potential energy Eg as a function of crack length LZ with constant applied stress (solid line). The energy barriers Ec and the discretization scale X are represented by the dashed curve. The time evolution of the crack length predi one. In reality both numerical simulations and tip progresses by jumps of various size and it dynamics can be understood by considering scale introduced in the previous section. cted by eq.(B) has to be considered an average experiments (see section Bp) show that the crack can spend a lot of time in a fixed position. This the existence of the characteristic microscopic ndeed, the elastic description of a material at a discrete level leads to a lattice trapping effect ba with an energy barrier which has been estimated analytically [21 larger than Lg. To get a physical picture of t . The other importa nt effect of the discreteness is that L. becomes he trapping we may consider a 2D square lattice

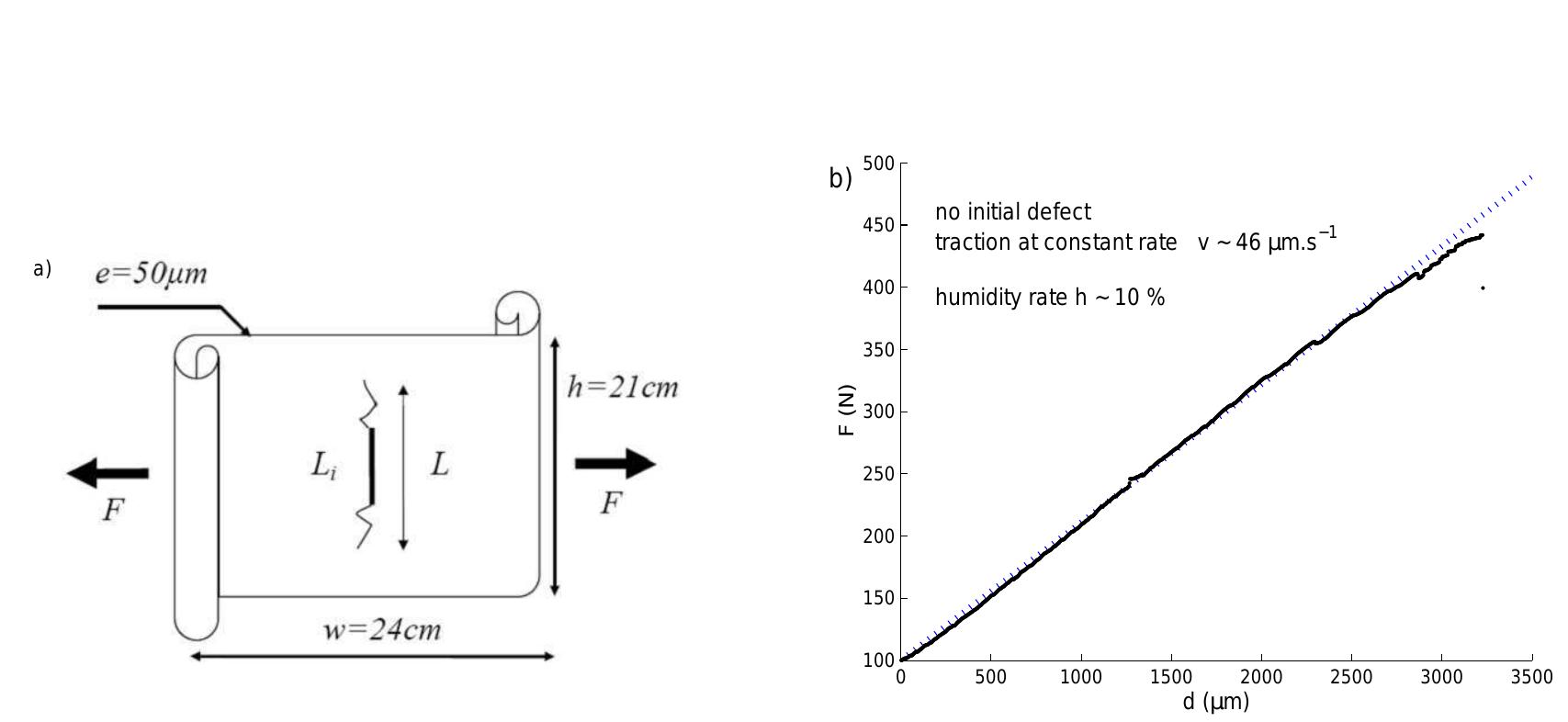

Figure 3: a) Sample geometry. b) Linear dependence between applied force and elongation until rupture.

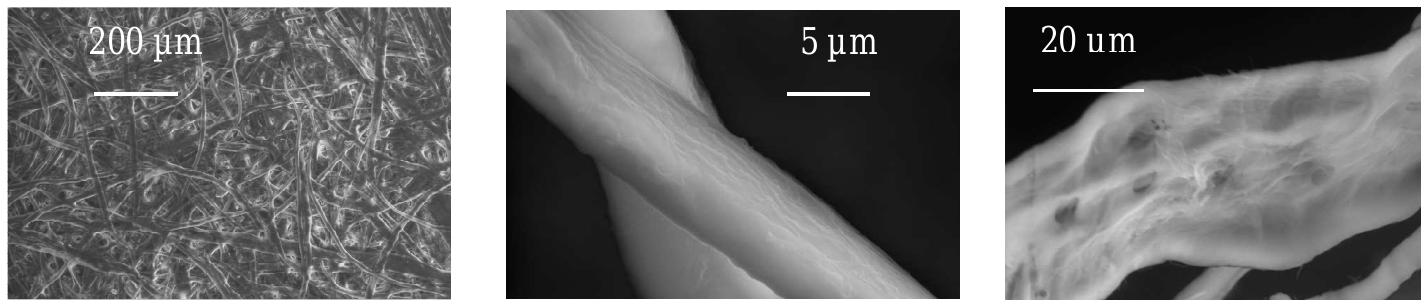

Sheets of fax paper in a dry atmosphere break in a brittle manner. This is evidenced by the elastic stress-strain dependence which is quasi-linear until rupture (fig. Bp). Another sign that rupture is essentially brittle is given by the very good match between the two opposite lips of the fracture surfaces observed on post-mortem samples. A sheet of paper is a complex Figure 4: Scanning electron microscopy performed at GEMPPM (INSA Lyon) shows the mi- crostructure of our samples and even the defects on the surface of a single fiber.

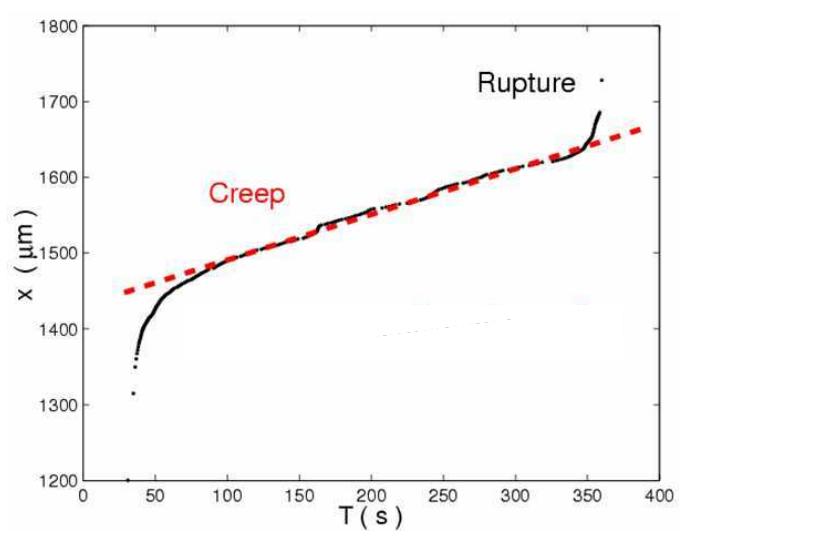

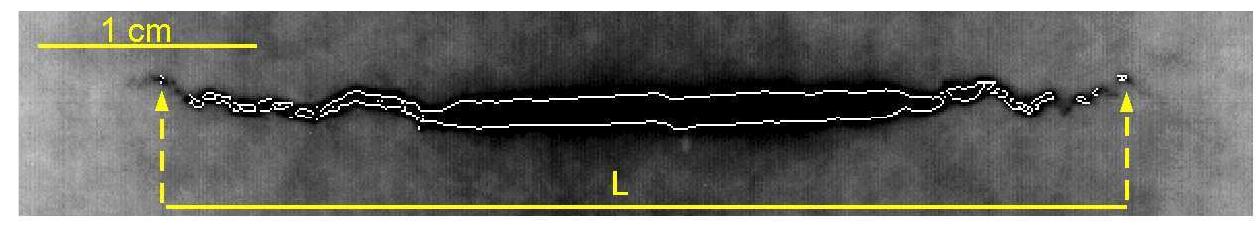

observe that the global deformation of the paper sheet during a creep experiment is correlated in a rather reproducible way to the crack growth whatever the rupture time. We use this property to trigger the camera at fixed increment of deformation (one micron) rather than at fixed increment in time. This avoids saturation of the onboard memory card when the crack growth is slow and makes the acquisition rate faster when the crack grows faster and starts to have an effect on global deformation. We acquire 2 frames at 250fps at each trigger and obtain around one thousand images per experiment. Image analysis is performed to extract Figure 5: Extraction of the projected crack length L from the crack contour detected.

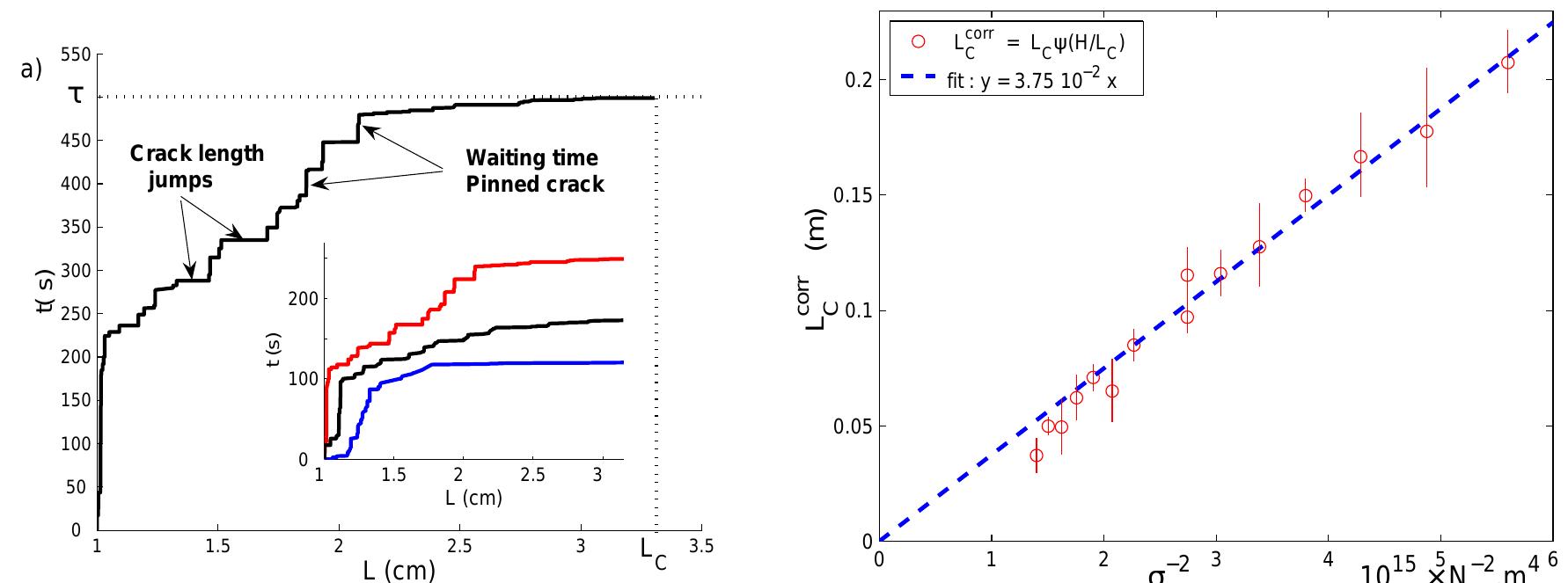

Figure 6: a) Typical stepwise growth curve for a creep experiment with an initial crack length L;, = 1cm submitted to a constant load F = 270N. The lifetime of the sample is 7 = 500s and the critical length L, = 3.3cm. In insert, a strong dispersion is observed in crack growth profile and in ifetime for 3 creep experiments realized in the same conditions. b) Critical length of rupture L, as function of the inverse square of the applied stress 1/07. The dashed line represents the best inear fit y = K?zx. Its slope permits us to estimate the critical stress intensity factor K,. Note that we introduce the finite height corrections in the critical length L°°"".

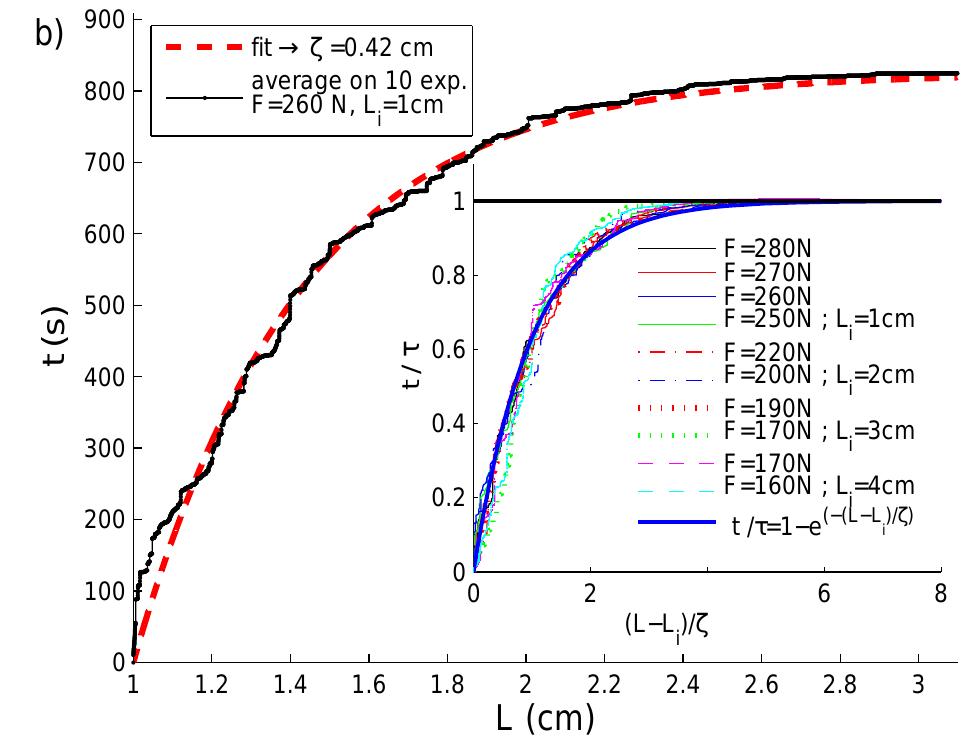

Figure 7: Statistical average of growth curves for 10 creep experiments realized in the same conditions (ZL; = lem, F' = 270N). The dashed line corresponds to a fit using equation eq. (5) with a single free parameter ¢ = 0.41cm. Insert: rescaled average time (t)/7 as function of rescaled crack length (Z — L;)/¢ for various initial crack lengths and applied stress. The solid line corresponds to eq. (8).

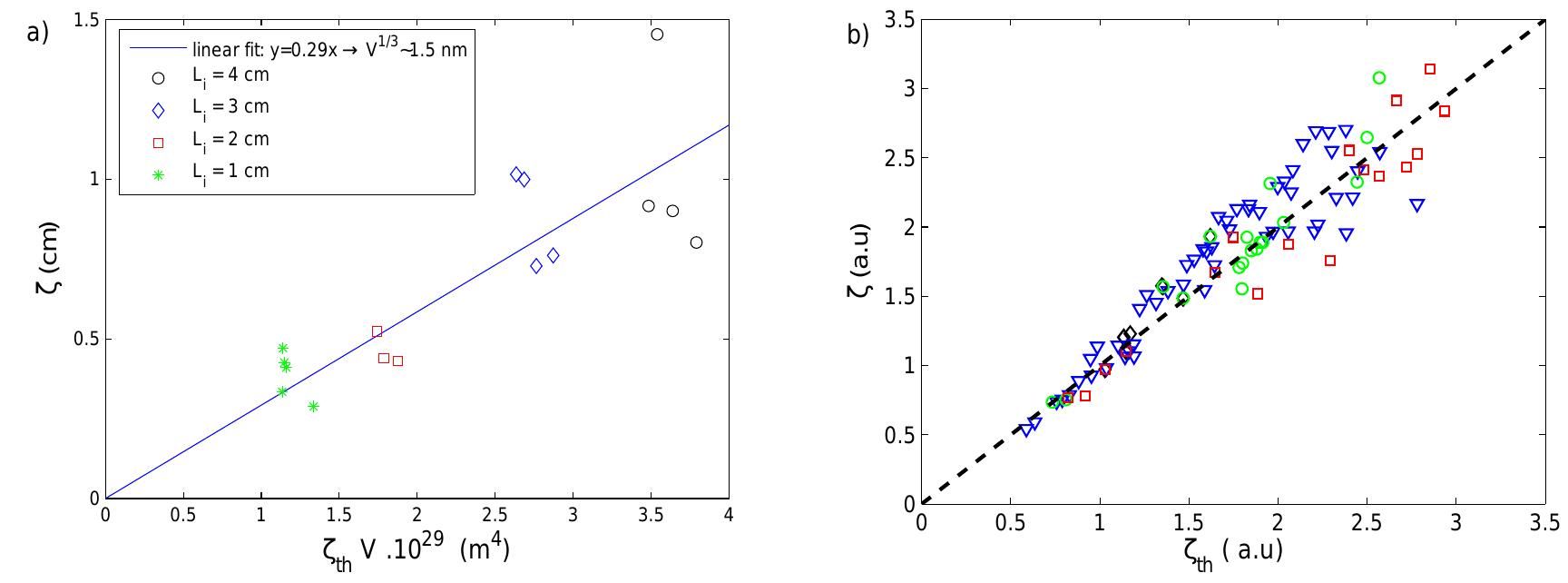

Figure 8: a) Experimental value of ¢ extracted from the average growth profile as a function of the prediction of the thermally activated rupture model. The line represents the best linear fit y = 2/V. Its slope permits us to obtain a characteristic length scale for rupture: V!/3 ~ 1.5nm. b) ¢ extracted from the average growth profile from numerical simulations fu versus the predictions of our model of activated rupture. Each point corresponds to an average over 30 numerical experiments, at least. The solid line shows the behavior expected from the model (slope =1).

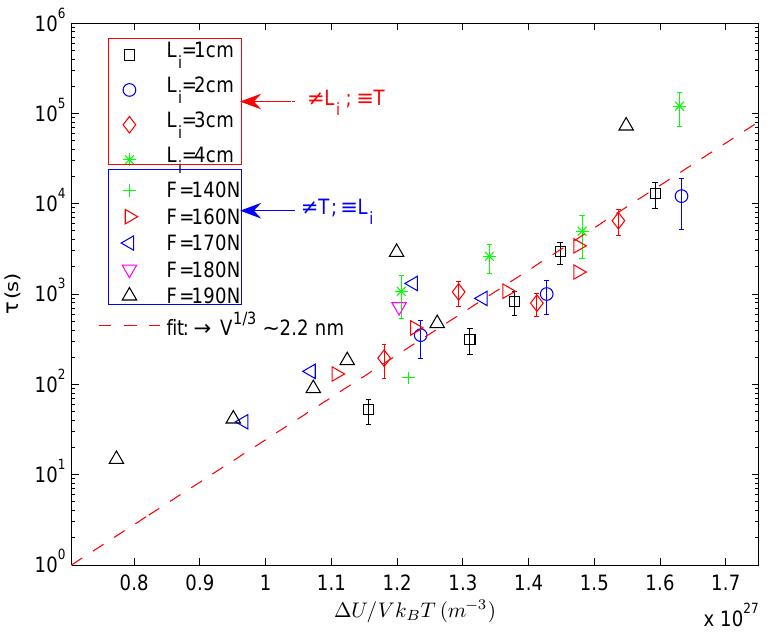

Figure 9: Logarithm of lifetimes as a function of the dimensional factor AU/(VkgT) predicted by eq. z for different values of L;, F and T. The slope of the best fit log Tr «x AU/kgT (dashed line) gives an estimation of the characteristic length scale V!/3 ~ 2.2nm. Data points without error bars correspond to non-averaged measurements obtained when varying temperature with DL; = 2cm and various fixed values of F’.

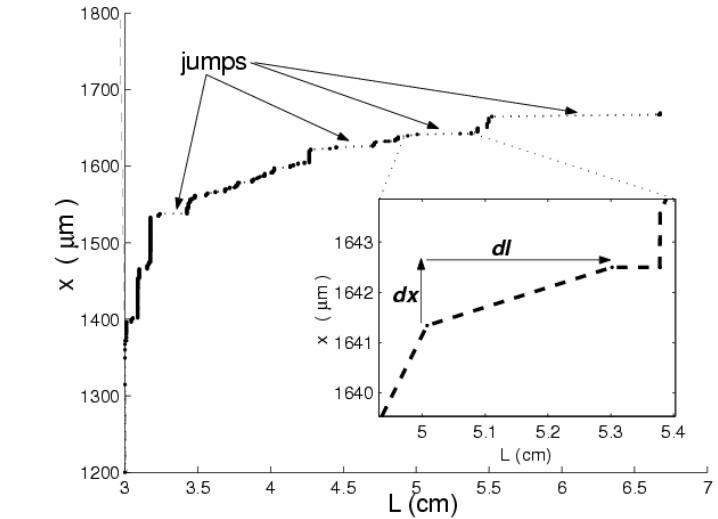

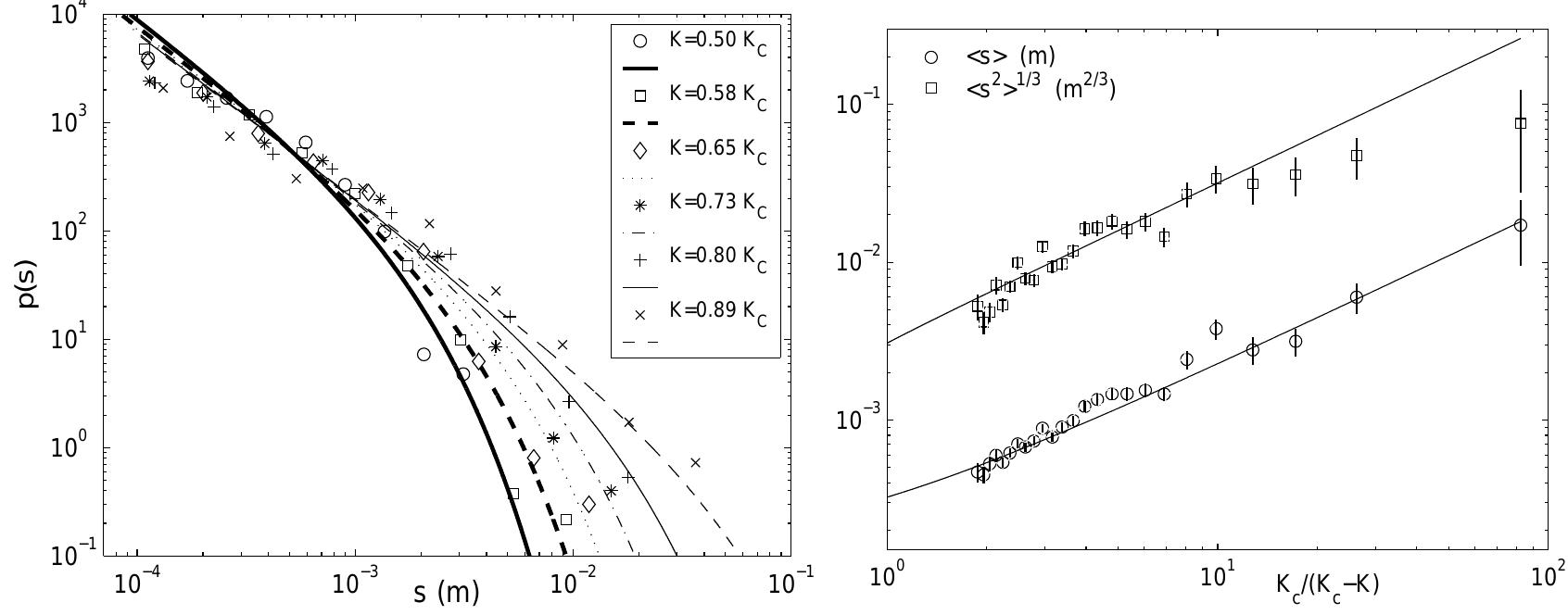

Figure 10: a) Deformation of a sheet of paper with an initial defect of LZ; = 3cm during an experiment at a constant load F' = 190N. b) Deformation of the sheet of paper as function of the crack length for the same experiment. We have observed on fig 4b) that the critical length L. for which the paper sheet breaks suddenly, scales with the inverse Saint of the applied stress 1/ o”. Thus, Le scales with o as the Griffith length Lg = 4Y7/(a 0”) does. In fact, we would normally expect that the are the same length [L6]. However, the lattice trapping model presented in paragraph predicts that L. and Lg can be two different lengths. In order to clarify which conclusion is correct, we have designed a method to compute the Griffith length in our experiments. For that purpose, we need to estimate the surface energy y needed to open a crack. Assuming

Figure 11: a) Average critical length (Z,) as function of the Griffith (Lg). The dashed line represents the best linear fit y = 3.6% while the continuous line is a guide for the eye showing y =a. b) Average Griffith length (L@) as function of the initial crack length L;. The line y = x is a guide for the eye.

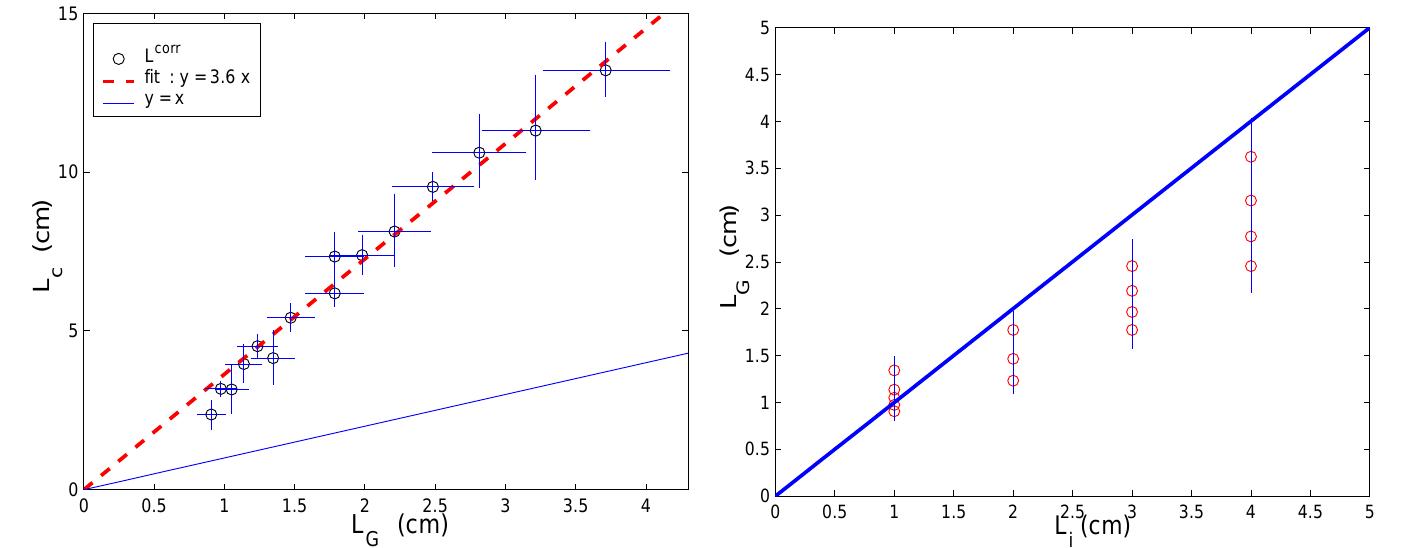

Figure 12: a) Probability distribution of step sizes for various values of stress intensity factor. Choosing A = 504m, the different curves are the best fits of eq {3} giving an average value V = (541) A®. b)The mean and cubic root of the variance from raw measurements of step sizes is well reproduced by the model (eq. 4) and eq. iE) plotted with A = 504m and V =5 A®.

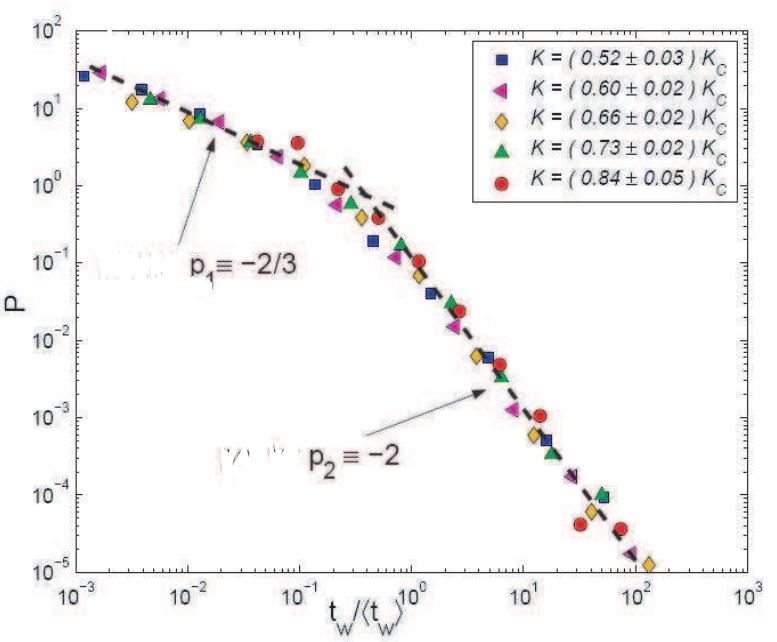

Figure 13: Distribution of waiting times between two crack jumps. All the distributions for various ranges of stress intensity factor collapse on a single curve when normalized by the average waiting time value corresponding to each range.

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

References (36)

- H. J. Herrmann, S. Roux, Statistical models for the fracture of disordered media (Elsevier, Amsterdam, 1990).

- M. J. Alava, P. K. N. N. Nukala, S. Zapperi, Adv. in Phys. 55, 349-476 (2006).

- S. S. Brenner, J. Appl. Phys. 33, 33 (1962).

- S. N. Zhurkov, Int. J. Fract. Mech. 1, 311 (1965).

- L. Golubovic, S. Feng, Phys. Rev. A 43, 5223 (1991).

- Y. Pomeau, C.R. Acad. Sci. Paris II 314 553 (1992);

- C.R. Mécanique 330, 1 (2002).

- A. Buchel, J. P. Sethna, Phys. Rev. Lett. 77, 1520 (1996);

- Phys. Rev. E 55, 7669 (1997).

- K. Kitamura I. L. Maksimov, K. Nishioka, Phil. Mag. Lett. 75, 343 (1997).

- S. Roux, Phys. Rev. E 62, 6164 (2000).

- R. Scorretti, S. Ciliberto, A. Guarino, Europhys. Lett. 55(5), 626 (2001);

- S. Santucci, L. Vanel, R. Scorretti, A. Guarino, S. Ciliberto, Europhys. Lett. 62, 320 (2003).

- R. A. Schapery, In Encyclopedia of Material Science and Engineering (Pergamon, Oxford, 1986), p. 5043.

- J. S. Langer, Phys. Rev. Lett. 70, 3592 (1993).

- A. Chudnovsky, Y. Shulkin, Int. J. of Fract. 97, 83 (1999).

- P. Paris, F. Erdogan, J. Basic Eng., 89, 528 (1963).

- A. A. Griffith, Phil. Trans. Roy. Soc. Lond. A 221, 163 (1920).

- B. Lawn , T. Wilshaw, Fracture of Brittle Solids (Cambridge University Press, Cambridge, 1975).

- L. Pauchard, J. Meunier, Phys. Rev. Lett. 70, 3565 (1993).

- S. Ciliberto, A. Guarino, R. Scorretti, Physica D 158, 83 (2001).

- B. Diu , C. Guthmann, D. Lederer, B. Roulet, Physique Statistique (Herrmann, Paris 1989), 272.

- M. Marder, Phys. Rev. E 54, 3442 (1996).

- R. Thomson, in Solid State Physics, edited by H. Ehrenreich and D. Turnbull (Academic, New York, 1986), Vol. 39, p. 1.

- D. Stauffer, Introduction to Percolation Theory (Taylor & Francis, London, 1991).

- S. Santucci, P-P. Cortet, S. Deschanel, L. Vanel, S. Ciliberto, Europhys. Lett. 74 (4), 595 (2006).

- S. Santucci, L. Vanel, S. Ciliberto, Phys. Rev. Lett. 93, 095505 (2004).

- A. Guarino, S. Ciliberto, A. Garcimartìn, Europhys. Lett. 47 (4), 456 (1999).

- H. F. Jakob, S. E. Tschegg, P. Fratzl, J. Struct. Biol. 113, 13 (1994).

- P.-P. Cortet, L. Vanel, S. Ciliberto, Europhys. Lett. 74, 602 (2006).

- J. Kierfeld, V. M. Vinokur, Phys. Rev. Lett. 96, 175502 (2006).

- E. Bouchbinder, I. Procaccia, S. Santucci, L. Vanel, Phys. Rev. Lett. 96, 055509 (2006).

- S. Santucci, K. J. Måloy, A. Delaplace, J. Mathiesen, A. Hansen, J. O. Haavig Bakke, J. Schmittbuhl, L. Vanel, P. Ray, Phys. Rev. E., 75 016104 (2007).

- F. Bueche, J. App. Phys. 28(7), 784 (1957).

- N. Mallick, P-P. Cortet, S. Santucci, S. Roux, L. Vanel. submitted. to Phys. Rev. Lett. (2006).

- P.P. Cortet, S. Santucci, L.Vanel, S. Ciliberto, Europhys. Lett. 71 (2), 1 (2005).

FAQs

AI

How does applied stress influence the lifetime of brittle materials during slow crack growth?add

The findings indicate that the lifetime τ of brittle materials significantly decreases as applied stress exceeds critical values, following an Arrhenius law. Experiments with fax paper demonstrated lifetimes varying from seconds to days based on stress intensity factors from 2.7 to 4.2 MPa·m^1/2.

What is the significance of thermal activation in crack propagation mechanisms?add

Thermal activation is identified as a critical trigger for crack nucleation in brittle materials under constant load. The model reveals that localized stress fluctuations due to thermal noise can exceed rupture thresholds, facilitating crack growth at the microstructural level.

How does the mean crack speed relate to the stress intensity factor K?add

The study quantifies that crack speed increases with heightened stress intensity factors K, establishing a threshold stress Kc of approximately 6 MPa·m^1/2. Beyond this threshold, experimental data indicates crack velocities surpassing 300 m/s.

What role does the lattice trapping effect play in the crack growth process?add

The lattice trapping effect modifies the Griffith energy barrier, resulting in a divergence of crack growth behavior. This effect leads to critical length Lc significantly exceeding the Griffith length LG, thereby altering the dynamics of crack propagation.

What statistical properties were observed in the stepwise crack growth dynamics?add

The analysis of crack growth reveals that larger step sizes in crack propagation exhibit a cutoff dependent on the stress intensity factor K, with distributions showing robust agreement with predicted power laws and divergence near critical thresholds.

![Figure 10: a) Deformation of a sheet of paper with an initial defect of LZ; = 3cm during an experiment at a constant load F' = 190N. b) Deformation of the sheet of paper as function of the crack length for the same experiment. We have observed on fig 4b) that the critical length L. for which the paper sheet breaks suddenly, scales with the inverse Saint of the applied stress 1/ o”. Thus, Le scales with o as the Griffith length Lg = 4Y7/(a 0”) does. In fact, we would normally expect that the are the same length [L6]. However, the lattice trapping model presented in paragraph predicts that L. and Lg can be two different lengths. In order to clarify which conclusion is correct, we have designed a method to compute the Griffith length in our experiments. For that purpose, we need to estimate the surface energy y needed to open a crack. Assuming](https://figures.academia-assets.com/43347752/figure_010.jpg) ](

](