The development of plant food processing in the Levant: insights from use-wear analysis of Early Epipalaeolithic ground stone tools (original) (raw)

Abstract

In recent years, the study of percussive, pounding and grinding tools has provided new insights into human evolution, more particularly regarding the development of technology enabling the processing and exploitation of plant resources. Some of these studies focus on early evidence for flour production, an activity frequently perceived as an important step in the evolution of plant exploitation. The present paper investigates plant food preparation in mobile hunter-gatherer societies from the Southern Levant. The analysis consists of a use-wear study of 18 tools recovered from Ohalo II, a 23 000-year-old site in Israel showing an exceptional level of preservation. Our sample includes a slab previously interpreted as a lower implement used for producing flour, based on the presence of cereal starch residues. The use-wear data we have obtained provide crucial information about the function of this and other percussive tools at Ohalo II, as well as on investment in tool manufacture, discard strategies and evidence for plant processing in the Late Pleistocene. The use-wear analysis indicates that the production of flour was a sporadic activity at Ohalo II, predating by thousands of years the onset of routine processing of plant foods.

Keywords: percussive technology, ground stone tool, functional analysis, use-wear, South West Asia, plant processing

1. Introduction

Recent research on percussive, pounding, grinding and abrading technology has yielded considerable insights on human evolution, especially with regard to the development of specific motor habits, skills and knowledge enabling the transformation and exploitation of new resources (e.g. [1–13]). This paper explores whether this technology was used for plant processing by hunter-gatherer societies of the Southern Levant. Our goal is to improve our understanding of the evolution of plant exploitation and food preparation techniques before the advent of farming in this geographical area.

In archaeology, percussive, pounding, grinding and abrading implements are generally classified as ground stone tools. Ground stone tools are part of a lithic toolkit that enables activities that chipped stones cannot perform. It should be noted that the terminology for ground stone tools often varies as a function of time period and geographical area. The term ‘percussive tools' refers for instance more specifically to implements used through percussion by ‘ … delivering a blow or a series of blows with an object, typically held in the hand … ’ [8, p. 60] and is more frequently employed when discussing the early phase of development of non-chipped stone tool technologies, as well as in research on tool use among primates.

This paper draws on some of the parameters emphasized by Leroi-Gourhan [14] in his classification of tools (table 1). Of particular significance to this classification is the work motion (or tool kinematics) used to transfer energy to the processed matter. More specifically, Leroi-Gourhan distinguished four categories of work motions1: (i) abrasion; (ii) percussion; (iii) indirect percussion (for motions requiring the use of an intermediated tool) and (iv) combined percussion and abrasion.

Table 1.

Parameters used to describe percussive tools following the classification proposed by Leroi-Gourhan [14].

Most ancient types of percussive tools generally fall into the category of implements operated by percussion (direct or indirect) and/or combined percussion and abrasion. Early Lower Palaeolithic examples comprise cupmarks, anvils, hammerstones and pounders (e.g. [19–24]). Implements mainly operating through abrasive motions, such as grinding slabs and handstones (also known as metates and manos), seem to have developed later in South Africa (e.g. [1,25, p. 537]; [26]) during the Middle Stone Age.

The present research focuses on ground stone tool types used in pairs. Typically, these pairs include a lower-passive implement and an upper-active one; together they are used to reduce matter into smaller particles either through abrasive motion (grinding) or through a combination of percussion and abrasion (pounding). Grinding and pounding are often critical to the consumption of certain plant resources, as they allow the separation of edible from non-edible parts and the breakdown of toxic products [27–31]. In addition, grinding and pounding technology permits the reduction of the edible fraction into different particle sizes (e.g. bulgur, flour), which enhances digestibility and caloric returns [29,31].

Investigating the evolution of ground stone technology is of particular relevance to the development of plant processing, including flour production (e.g. [31–37]). We use the remains from Ohalo II, a 23 000-year-old fisher-hunter-gatherer's campsite located in the Southern Levant (Israel) to discuss the emergence of flour production in the Levant. This region represents one of the earliest centres of plant domestication. Importantly, Ohalo II predates the establishment of farming communities in the area by ca 12 000 years [38–40]. The site has yielded the earliest evidence in the area for the production of flour from wild barley and oats, as suggested by the recovery of organic residues from the surface of a basalt slab [31,41]. The issue of flour preparation at Ohalo II is reassessed here in the light of the analysis of a selected collection of ground stone implements uncovered at the site. These tools are examined from the perspective of use-wear analysis, a complementary approach to residue analysis for assessing tool function.

(a). The site of Ohalo II

The site of Ohalo II is noteworthy for its exceptional degree of preservation of organic remains, and investigations at the site have contributed greatly to our understanding of past patterns of plant exploitation [42–46]. Located on the southwestern shore of the Sea of Galilee in Israel, the site was submerged shortly after it was abandoned and remained as such for millennia [47–50]. The camp includes the remains of six brush huts. In Brush Hut 1, the charred building materials of the walls were identified to the species level: thick branches of Tamarix (tamarisk), Salix (willow) and Quercus ithaburensis (oak) were covered by smaller branches of plants such as Atriplex/Seidlitzia (orach/seidlitzia) and Prosopis (mesquite), as well as leaves and grasses [51]. Additional in situ features include a grave, a stone structure and hearths. Grass bedding encompassing charred bundles of Puccinella convoluta (a perennial grass) stems and leaves covered with a thin layer of compact clay was found on the bottom floor of Brush Hut 1 [52]. Of relevance here is the studied assemblage of approximately 150 000 charred and un-charred seeds and fruit remains comprising approximately 150 identified taxa [42–44,46,53,54]. This diversity of plant taxa supports the hypothesis of a broad-spectrum exploitation of plants long before the onset of agriculture ([53] and references therein).

The presence of cereals in the botanical assemblage is noteworthy. For example, on Floor II of Brush Hut 1 there were approximately 60 000 seeds and fruits, of which 606 are of Hordeum spontaneum [46]. On Floor III there were approximately 55 000 specimens, of which 1920 are from the same species [54]. Given the exceptional level of preservation and the extensive evidence of human activities at the site, it is safe to argue that cereals in general, and wild barley in particular, were commonly brought into the hut and processed there.

2. Material and methods

One basalt slab, found in situ on the second floor of Brush Hut 1, was the subject of residue analysis as it was found carefully set on a patch of yellow sand and supported by several pebbles [41]. The object is about 45 cm long and has no flake scars or other evidence of shaping. An initial analysis, published by Piperno et al. [31], focused on the upward-facing surface of the slab from which a total of 150 starch grains were recovered. Of these, 127 were of grasses, including 78 grains attributed to the genera Hordeum, Triticum and Aegilops. The study concluded that the slab was used to process a selected range of wild cereals and that flour was used for baking dough [31]. A more recent analysis that included additional samples from both faces of the slab as well as sediment samples from neighbouring deposits was consistent with the earlier results and allowed the identification of an additional species processed on the slab, namely oat (Avena) [41]. By contrast, the sediment samples were very poor in starch residues. The use-wear analysis presented here aims at shedding further light on flour production at the site, using the slab from Brush Hut 1, along with 17 additional ground stone objects.

(a). Use-wear analysis

Use-wear analysis is one of the most rigorous methods for assessing the function of ancient tools: it provides an independent, and where relevant, a complementary approach to the analysis of residues [55]. Research in material sciences has shown that interacting surfaces in relative motion often develop wear. In tribology—a science dedicated to the study of friction and wear—wear is defined as: ‘a continuous damage process of surfaces’ [52]. In this approach, different types of wear are distinguished based on their mechanism of formation including adhesive, fatigue, abrasive and tribochemical wear [56,57]. In archaeology, use-wear approaches generally emphasize the analysis of damage on the surfaces of tools (e.g. [58,59]). This damage can potentially occur in various contexts that involve interaction between the tool surface and another element. For instance, manufacture, use or natural processes such as weathering or soil abrasion may generate damage on the surface of an implement (e.g. [58,60,61]). Several experimental programmes have investigated the wear characteristics produced in these and other contexts (for ground stone tools, see [62] and references therein). The approach focuses mainly on observations at various magnifications including macroscopic (with the naked eye and with a stereomicroscope, commonly from 5× to 50×) to microscopic scales (generally from 50× to 500×). The main goal of the use-wear approach is to gain knowledge regarding the use of implements; accordingly, special attention is paid to variation in wear characteristics in relation to the kinematics of tool use and the matters that were processed.

When feasible, residue analysis may enable the identification of the transformed material at a higher degree of precision than is possible with use-wear observations. For instance, experiments with grinding and pounding tools made of basalt have shown that inferences are generally limited to the identification of broad categories of processed matters, such as greasy/non-greasy vegetal matter, animal tissues or abrasive-minerals, etc. [62–65]. Nonetheless, the study of use-wear, when combined with the analysis of tool morphology, can convey critical information about the kinematics of a tool. A use-wear approach also allows the analysis of the life history of implements, from manufacture to discard ([65] and references therein). These data are often central to our understanding of past socio-economic organizations, as they may improve our understanding of patterns of use of a particular resource and its economic and symbolic significance (e.g. [66]).

Because the methodological framework used in the use-wear analysis of the Ohalo II material has been discussed elsewhere [62,63,65,67], only a few brief comments are necessary here. Criteria of particular importance to the present analysis include the general aspect of the surfaces as observed by the naked eye, the damage affecting the groundmass and the phenocrysts (observed at low and high magnifications), as well as the presence and characteristics of micropolish identified at high magnifications. High magnification analyses were performed using direct observation of the objects under a microscope or, more commonly, on acetate casts. Acetate casts typically consisted of rectangles of 4 × 2.5 cm made at different locations on the tool surface after observation at various magnifications. Areas of interest (e.g. internal and external surface) and variation in use-wear characteristics were sampled. In addition to allowing the observation of large objects that cannot easily be placed under a standard microscope, casts often yield valuable data pertinent to the study of micropolish [68,69]. The optical instruments employed in this research include four stereomicroscopes (Zeiss, Leica Wild, Nikon SMZ1000 and Nikon SMZ 745) used for observations between 5× and 50× and two compound metallographic microscopes (Olympus BHMJ series and Nikon Eclipse LV-150), equipped with differential interference contrast (DIC) systems and used for observations between 50× and 500×.

(b). The sample

The assemblage of ground stone tools (n = 71) includes basalt and limestone implements [70]. We selected a range of tools that could have been used in plant processing activities, as assessed by the overall morphology of the objects. The studied sample consists of 18 artefacts, all retrieved from brush hut floors. These comprise six lower-passive implements (the large slab discussed previously and five shallow bowls), as well as 12 pebbles that were morphologically consistent with grinding or pounding upper-active implements. Most of the artefacts are broken, except for one pebble and the slab. The presentation of the results begins with the analysis of the slab followed by that of the other tools.

3. Results

(a). Analysis of the Locus 1 large slab

The overall shape of the slab is trapezoidal in plan and plano-convex in cross section (figure 1). The flattest surface of the slab and its opposite more convex surface are here referred to as faces 1 and 2, respectively. On both faces, damage related to post-depositional alterations, such as large and isolated striations, was identified (electronic supplementary material, figure S1). Face 1 (the upward-facing surface) also shows superficial spall scars. These scars and large striations have a fresh aspect suggesting that they were formed recently. Despite these observations, post-depositional alterations were limited and did not significantly affect the use-wear analysis of the original surfaces.

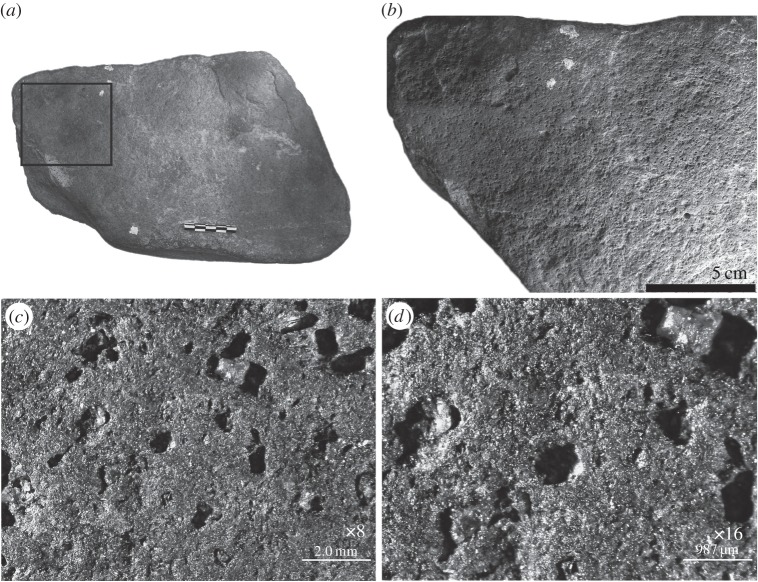

Figure 1.

Ohalo II Locus 1 slab, view of the upward-facing surface. Starch grains were retrieved from this face [31,41].

Faces 1 and 2 present the aspect of a weathered block of basalt with a smooth texture and a sinuous morphology of the surface in cross section. Naked eye observations of the slab revealed no clear signs of shaping by flaking, pecking or abrasion. No evidence of grinding or abrasive operations was observed at this scale. Experiments have demonstrated that grinding or abrasion generally produce a levelling of the surface, or the formation of plateaus on the highest parts of the microtopography (e.g. [63,67,71–76] and see examples in electronic supplementary material, figure S2). Macroscopically, the most conspicuous use-wear consists of two small adjacent shallow depressions or pits towards the centre of face 1 (figure 2). These pits may indicate intentional manufacture and/or use. At low magnifications, impact marks and grain microfractures in the pits point to contact with a hard matter in a percussion motion. However, some levelling of the grain's summits and a slight reflective sheen, characteristic of contact with a soft and pliable matter, are also observed. These features most probably indicate an abrasive motion (figure 2).

Figure 2.

Macroscopic view of the pits observed on the Ohalo II Locus 1 slab. (a) General view of face 1. The square indicates the zone where photos (b) and (c) were taken.

In percussive technology, the formation of pits is symptomatic of activities such as nut-cracking or bipolar percussion, among others (e.g. [11,21,24,77–79]). The experimental evidence suggests that pit formation on the lower-passive implement more likely results from percussion with a hard material, either intentional or accidental. For instance, during nut-cracking, impacts eventually concentrated in pits can form when the hammerstone accidentally strikes the anvil, whereas the area of the anvil in contact with the nut rather shows a shallow and smooth depression (L. Dubreuil 2004, personal observation). Pits can also purposely be made by pecking the anvil to produce a depression where the nut can be placed. On the Locus 1 slab, the irregular shape diffuse limits and shallowness of the pits argue for modification through use rather than manufacture. As previously described, evidence of abrasion also occurs within the pits, which attests to a pounding type of motion (combination of percussion and abrasion).

Three other smaller concentrations of impacts were identified at low magnifications (electronic supplementary material, figure S3). Grain crushing and microfractures are common in these concentrations and no evidence of abrasive contact was found. However, grain levelling and levelling of the microrelief—unconnected with pits—were seen at low magnifications on one end of the slab. A kinematic assessment of the slab surface relates the presence of grain levelling and levelling of the microrelief to abrasion resulting from grinding (figure 3).

Figure 3.

Wear related to abrading on one extremity of the Ohalo II Locus 1 slab, macroscopic observations: (a) general view of face 1, with a square indicating the zone where abrasion wear is observed; (b) close-up on the zone with abrasion; (c) and (d) observations at low magnifications.

These types of damage are not documented on face 2, which is consistent with a naturally weathered surface: grains are clearly distinguishable (with interstices between them) and the levelling of the microrelief or of the grain's summit is poorly developed (electronic supplementary material, figure S4). Face 2, therefore, does not show clear evidence of use. Analyses at high magnifications are in agreement with observations made at low magnifications regarding patterns of grain alterations. No well-developed micropolish was observed on the faces of the slab. However, a dull sheen is documented on face 1.

In essence, the use-wear analysis indicates that the slab was used as a lower implement, as indicated by pounding marks in the pits, limited evidence of grinding or abrasion on one end of the object, and small impact clusters in several areas of face 1. Except for the small impact clusters, the use-wear characteristics of the slab are compatible with the processing of non-greasy vegetables, such as cereals. However, use-wear is too poorly developed to allow a more precise identification of the processed matter. These results, along with the residue analysis, suggest that the slab was used for the processing of seeded grasses, such as cereals, to remove the non-edible parts of plants and/or to reduce the seeds into smaller particles. The evidence is compatible with the production of flour as well as the reduction of seeds into coarser fractions, including bulgur as recently suggested by Snir et al. [54]. However, the poor development of grinding and pounding wear indicates that the object was not used for processing large quantities of materials. It is also probable that the slab was utilized in other activities, perhaps as a working slab or an anvil, as suggested by the presence of impact clusters. From a use-wear perspective, the tool would best be defined as a multifunctional working slab rather than a one-task grinding slab.

(b). Possible active tools (n = 12)

Active implements that could have been used for plant processing were also assessed in this study. The selection of objects was based on size, morphology and potential presence of use-wear consistent with utilization as an upper-active implement in grinding, pounding or abrading operations. Twelve objects were analysed in detail. All items are small weathered blocks or pebbles. Although 11 of 12 objects are broken, the estimated size of the objects suggests that they were all hand-held. Of the twelve implements, only two present unambiguous traces of utilization (table 2).

Table 2.

The Ohalo II tools, with use-wear or evidence of manufacture, discussed in this study.

| reference | type | raw material | traces of manufacture | wear related to use |

|---|---|---|---|---|

| OHII 91/93 | slab | basalt | pitting? | multifunctional, grinding, pounding and percussion |

| L12-A95d | shallow bowl (3 fragments) | basalt | final stages: pecking and abrasion | small spot of micropolish possibly related to mixing, light pounding |

| OII 13a-48 | shallow bowl | basalt | final stages: pecking and abrasion | |

| OHII L12-A99b and OHII L12-C94cd | shallow bowl 2 refitting fragments | basalt | recycling of L12-C94cd in pounding activity | |

| 02–157 | shallow bowl | limestone | final stages: pecking, abrasion and carving; possible evidence of coating | |

| OHII 1079 B87d 90–1360 | shallow bowl | limestone | final stages: pecking, abrasion and carving | small spot of micropolish possibly related to mixing, light pounding |

| OHII-1a57 | pebble | basalt | no evidence | skin processing |

| OHII-1a69 | pebble | basalt | probably used as an unmodified pebble | percussion, pounding and grinding; probably used for processing mineral matter |

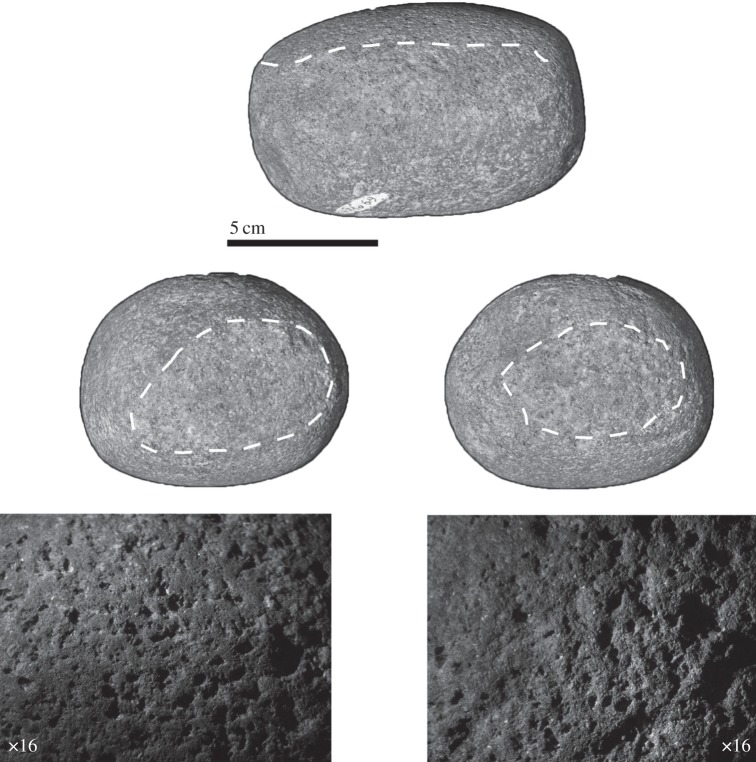

One of the objects (OHII-1a57) shows a dark and shiny surface visible by the naked eye. Micropolish consistent with skin processing [62,80] was identified on this tool (electronic supplementary material, figure S5). The other implement (OHII-1a69) is a natural pebble with a range of damage including impact marks on one face and levelled surfaces on both ends. On one of the ends, this levelling is associated with impact marks and removals. Low magnification analysis revealed additional impact marks on the sides of the pebble and abrasive wear on one of the large faces. Overall, use-wear characteristics suggest three types of work motions for this tool: (i) percussion (for one end and the side of the implement), (ii) pounding (combination of percussion and abrasion, seen on the other end) and (iii) abrasion (on one of the flat faces; figure 4). All of the working surfaces were most likely used for processing hard mineral matter (perhaps in flint knapping or for the production of shallow bowls) as grain microfractures dominates, and potential striations are observed. However, further residue analysis may help in the identification of the type of matter processed with the tool.

Figure 4.

Examples of macroscopic wear observed on object 1a59 (active tool). The dotted lines indicate the limits of various wear surfaces. End 1 (on the left) shows a combination of percussion and abrasion at low magnifications, while the surface shows a smooth texture and domed morphology in cross section. Note that the darker spots correspond to natural holes. End 2 (on the right) is dominated by impact marks and the surface shows a rough texture and an irregular cross section. Limits of the area with impact marks can be seen on the top left side of the photo.

The absence of unambiguous wear on the other pebbles does not necessarily mean that these objects were not used. For instance, certain activities may not leave use-wear on the tool surface (e.g. stones used for boiling, construction, etc.). Moreover, the intensity of utilization might have been too low to produce use-wear. Experiments have shown that the development of diagnostic use-wear is generally more gradual on ground stone tools than on flaked artefacts (e.g. [67]). In general, the slower development of use-wear on ground stone tools may be accounted for by the coarse grain size and/or loose cohesion of the raw materials employed in the production of some ground stone tools. The use context, which may involve only brief contacts with a small area of the tool, could also explain the lack or light development of use-wear on some objects. Moreover, in archaeological contexts, post-depositional processes may remove use-wear initially present on the implements. Regarding this last point, it should be noted that patination was observed on several implements in the collection of ground stone tools from Ohalo II, which may have been caused by long immersion in water. Unfortunately, we lack data on how these burial conditions may affect use-wear preservation.

(c). The shallow bowls (n = 5)

While the slab and the pebbles attest to the utilization of ad hoc or slightly modified implements, the five shallow bowls examined here are indicative of significant investment in manufacture. They also show complex life histories with evidence of recycling and, perhaps, intentional breakage.

Three shallow bowls are made of basalt and two of limestone. All five were entirely modified to produce a specific type of vessel, also known as ‘platters' [81]. At Ohalo II, these tools have an oval to round shape in plan; the rims are typically lower, and the convexity of the interior surface, less pronounced, than in mortars. All the shallow bowls uncovered at Ohalo II are fragmented; analyses aimed at reconstructing their initial shape are in progress. Some of the manufacturing stages are documented on the tool surfaces. The techniques that we documented include pecking, abrasion, chiselling and carving, a range of approaches also seen in later periods that coincided with the development of stone vessel manufacturing technology (e.g. [82] and references therein). Although small, the assemblage provides evidence for a wide spectrum of techniques, including elaborate finish of external and internal surfaces. Importantly, the smallest object (02–157) was perhaps coated with an unidentified material (electronic supplementary material, figure S6).

A critical issue is whether the shallow bowls served for plant, and more particularly, flour processing. Shallow bowls can generally be described as an intermediate form between grinding slabs and mortars; potentially they can be used as lower-passive implements to reduce plant materials into small particles. Because experiments on vessel manufacture and use are far more limited than for grinding and pounding implements [67], the analysis of use-wear on shallow bowls mostly focused on comparisons between the internal and external surfaces as well as on evidence of overlapping wear. Our approach assumes that traces related to use are more likely to occur on the internal surface of the implements and be superimposed on manufacture wear.

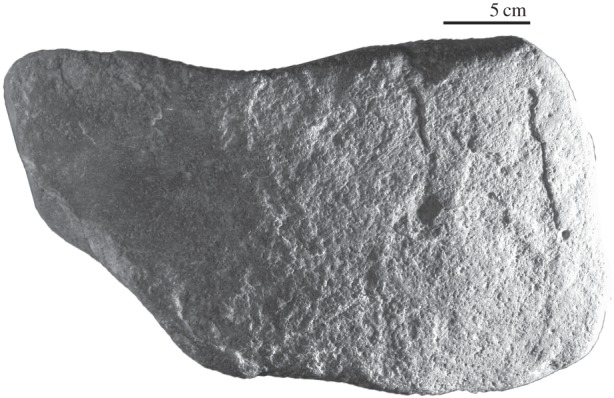

Potential traces of utilization were found on the surface of three implements. In two cases (L12-A95d and B87d-90–1360), the wear was observed at high magnifications. These traces consist of localized patches of translucent to opaque, slightly reflective micropolish with a fluid texture and diffuse limits that penetrate into the interstices (figure 5 and electronic supplementary material, figure S7). Micropolish characteristics seem to indicate contact with a soft and pliable matter, in marked contrast with wear observed on mortars and grinding slabs used for grinding cereals. In general, the actions performed with the two shallow bowls were not abrasive and were presumably closely related to mixing or unforceful pounding.

Figure 5.

Use-wear indicative of utilization observed at high magnifications on the internal surface of a shallow bowl (B87d 90–1360) from Ohalo II.

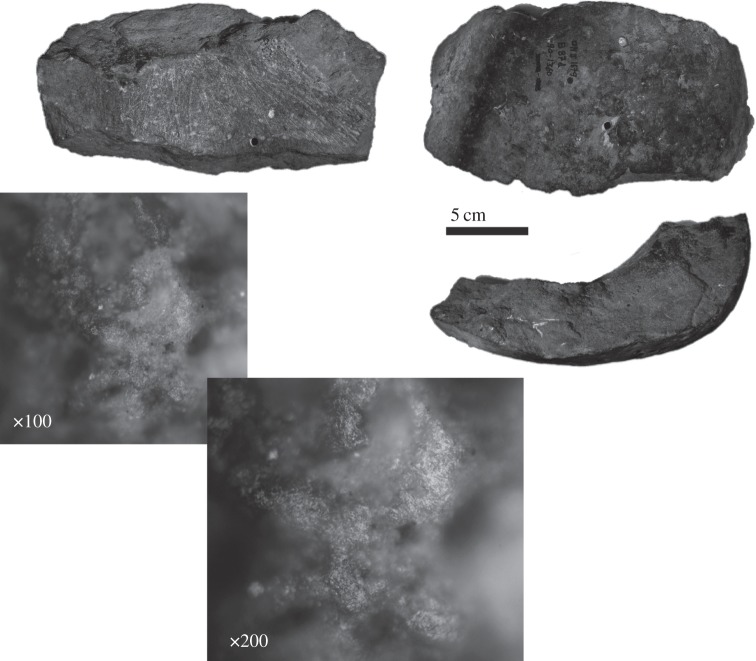

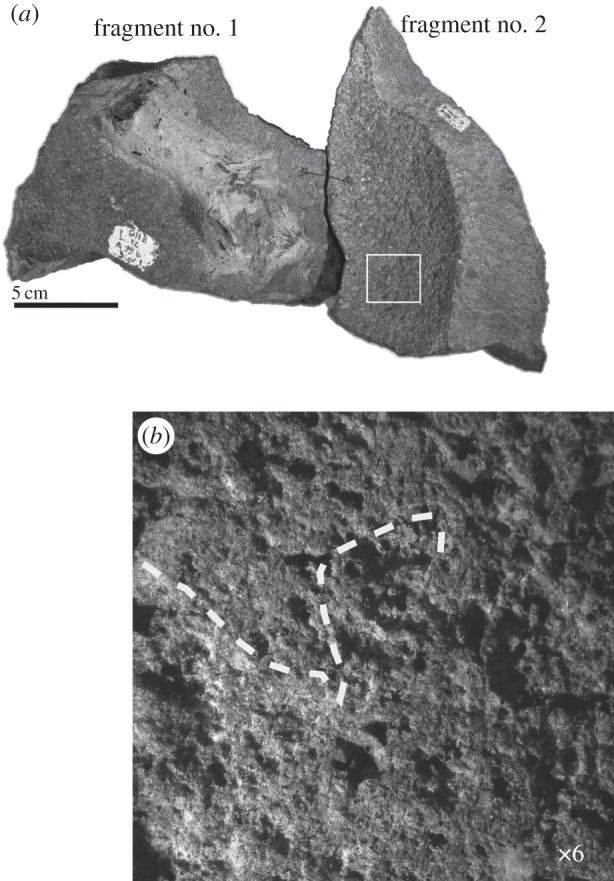

Distinct types of wear were observed on one of the two refitted portions of a shallow bowl fragment (L12-C94cd and L12-A99b, figure 6 and electronic supplementary material, figure S8). The internal surface of fragment no. 1 is levelled by pecking and abrasion. These types of wear, which were also identified on several other objects in the assemblage, possibly reflect the last stages of tool manufacture. Abundant impact marks and irregular microrelief of the internal surface characterize fragment no. 2. The impact marks tend to cluster towards the centre of the fragment, although they also occur at some distance from it. These marks were produced after manufacture. Levelled plateaus were observed at low magnifications, which indicate that percussion was associated with abrasive motions. The relative chronology of the use-wear suggests that fragment no. 2 was used after breakage in pounding activity. Evidence of contact with a hard and abrasive matter is common on this object. However, the fact that the wear associated with this secondary use is lightly developed suggests that this phase of utilization was of relatively short duration.

Figure 6.

A refitted shallow bowl from Ohalo II: (a) refit of L12-A99b (fragment no. 1) and L12-C94cd (fragment no. 2). Evidence of secondary use is found on fragment no. 2. The square indicates the zone where low magnification photos were taken. (b) Observations at low magnifications showing fragment no. 2 surface with impacts and levelling (bellow the dotted line) corresponding to a secondary phase of utilization after the tool was broken.

Overall, the sample of shallow bowls shows only limited evidence for use in grinding and pounding activities (table 2). When present, such evidence is associated with episodes of tool recycling. Importantly, the use-wear data indicate these objects were most likely used as containers, or for mixing materials rather than for grinding.

Patterns of fragmentation in the shallow bowl sample require a few additional comments. That the bowls are all broken at Ohalo II was not unexpected, given that this is a common trend for Levantine ground stone tools of the Epipalaeolithic and Neolithic periods [82,83]. Causes of fragmentation are difficult to identify, but likely include thermal fracture, accidental or intentional breakage associated with tool use and curation as well as post-depositional processes. At Ohalo II, all the shallow bowl fragments show multiple removal scars. These features are abundant on item OII 13a-48 (electronic supplementary material, figure S7). The object shows at least 10 impact marks along the edge of the internal surface and has removal scars all along its sides. On some shallow bowls, multiple impact marks or micro-chipping along the edge suggest failed attempts at flaking the piece. This pattern does not seem consistent with utilization as the impact marks tend to be concentrated along the edges rather than be distributed all over the surface. Nor are these patterns consistent with recycling. Indeed, only one fragment shows clear signs of use after breakage, as mentioned above. Further analyses are required to fully document recycling in this sample.

Intentional breakage of ground stone implements has recently been the focus of much attention [83–89]. Ethnographic studies indicate that this behaviour may be intended to release the spirit from an object or to express compassion for, and/or prevent revenge from, a deceased person (e.g. [86,90]). As pointed out by Wright [83], intentional breakage occurring during ‘potlatch-type’ activities may be relevant to certain contexts. At Çatalhöyük, the spatial distribution and life history of quern fragments led Wright [83] to conclude that this type of grinding implement was discarded or destroyed when a house was abandoned. In the Holocene record of the Balkans, the incompleteness of the broken objects was interpreted as indicating that missing fragments were deposited elsewhere in a process that might have aimed at linking people with places [84,85].

It is noteworthy that two shallow bowls (objects 90–1360 and 02–157) at Ohalo II were found lying face-down on the floors of Brush Huts 3 and 13, respectively. No fragments from these objects were recovered on those floors or anywhere at the site [91]. The fact that these shallow bowls are broken and the possibly deliberate ‘burial’—face-down—of the objects onto brush hut floors warrant further analyses. If confirmed, these patterns may represent the earliest examples in the region of deliberate breakage and burial of selected objects in particular locations and settings (e.g. [48,91–93]). Additional analyses may shed more light on purposeful breakage of shallow bowls at the site. More specifically, comparisons with other tools of the assemblage and in-depth spatial analyses of the objects should prove useful in this respect.

4. Discussion and conclusion

Although there are many cereal seeds at the site, only 71 ground stone tools were found at Ohalo II, of which less than 25% are potentially associated with grinding or pounding [70]. Similarly, of 2221 flint tools, only a handful of flint blades have sickle gloss. In other words, while cereals were commonly harvested, brought to the site, and likely processed for consumption, the ‘typical’ tools associated with plant harvesting and processing were not, at this early stage, a regular component of the local toolkit.

Importantly, the shallow bowls demonstrate that the knowledge and skills required for the production of sophisticated well-shaped ground stone tools existed prior to the Natufian (ca. 15 500–11 600 Cal BP), when the quantity, variety and quality of ground stone implements in the Southern Levant reached high levels [29,94–98]. Yet, investment in tool manufacture at Ohalo II was not directed towards the systematic production of grinding and pounding implements. Intentional fragmentation is suggested for the shallow bowls of Ohalo II; however, further analysis is required to assess the scale and implications of this practice.

Evidence of grinding and pounding is present on a slab used without prior modification. Use-wear is consistent with the processing of non-oily vegetable such as cereals, as indicated by the residue analysis. Use-wear evidence also suggests that the slab was most probably a multi-purpose tool, while grinding and pounding were not intensive. Active implements used for grinding and pounding cereals on the slab were not found in our sample. Among the 11 potential hand-held tools analysed in this study, only two showed unambiguous use-wear. One of these tools presents evidence of skin processing and the other is associated with percussion, pounding and grinding. Wear indicative of contact with a hard and abrasive matter such as stone dominates.

In essence, the use-wear evidence for flour production is meagre at Ohalo II. The use-wear analysis suggests that, if practised, flour production using stone implements was an occasional rather than routine activity. This seems to be a common feature of early archaeological examples of grinding or pounding plant food using stone tools, with the exception of cases from China and Australia [36,68]. That being said, it should be noted that studies of ground stone tools that include detailed analyses of use-wear and organic residues are recent and limited to a few geographical regions. In Europe and South West Asia, the early evidence for flour production appears very limited so far and the tools would not have allowed the processing of large quantities of matter and/or were not intensively used [99,100], as seems to have been the case at Ohalo II. These early examples likely attest to sporadic events of plant processing, with flour being no more than a marginal dietary item. Moreover, the production of coarser by-products, such as bulgur, can be achieved with grinding and pounding implements, and it seems important to consider the diversity of potential recipes for each plant. From the perspective of cultural niche construction theory, these early sporadic experiments in grinding or pounding plant food can perhaps be viewed as efforts made by small-scale societies to increase the number of economically valuable resources. They may, therefore, represent phases of exploration, social learning and participation in the construction of ‘traditional ecological knowledge’ [101]. Alternatively, because plant food processing such as flour production is, according to proponents of foraging theory, a low-return activity, it might have constituted an unattractive option in forager economies for most of the Pleistocene [102]. To further test the interpretations presented in this paper, additional analyses of ground stone tools dated to the Palaeolithic and Early Epipalaeolithic periods are required. Shallow bowls, mortars and pestles have been identified at several sites of the Levant (e.g. [29,95]) and the functional analysis of these tools may shed additional light on flour production before the shift to farming. Lastly, experiments relating to pounding activities, the processing of seeded grasses and the production and use of shallow bowls may also prove very productive.

Supplementary Material

Supplementary figures

Acknowledgements

The authors are thankful to Ignacio de la Torre and Sathosi Nishida for their invitation to participate in this special issue. The authors thank Hugues Plisson and Dror Maayan for providing photos, as well as Naama Goren, Gonen Sharon and Aliette Lompré for allowing access to their reference collection of percussive tools. The authors are grateful for useful comments and suggestions provided by Marit Munson and the anonymous reviewers.

Endnote

1

It should be underlined that this framework only provides a broad description of the tool kinematics, and more parameters should be added to portray fully the way a tool is operated and how the task is accomplished (e.g. [8,15–18]).

Data accessibility

The datasets supporting this article have been uploaded as part of the electronic supplementary material.

Authors' contributions

L.D. carried out the use-wear analysis, designed the study and drafted the manuscript; D.N. carried out the excavation at Ohalo II, collected the field data, participated in data analysis and the design of the study, and helped draft the manuscript. All authors gave final approval for publication.

Competing interests

The authors declare no competing financial interests.

Funding

The Ohalo II project was generously supported by the Irene-Levi Sala CARE Archaeological Foundation, the Israel Science Foundation (nos 831/00 and 711/08), the Jerusalem Center for Anthropological Studies, the L.S.B. Leakey Foundation, the Stekelis Museum of Prehistory in Haifa, the MAFCAF Foundation, the National Geographic Society and the Israel Antiquities Authority. Funding for the use-wear analysis of Ohalo II percussive tools was provided by the Social Sciences and Humanities Research Council of Canada (L.D.).

References

- 1.Mc Brearty S, Brooks A. 2000. The revolution that wasn't: a new interpretation origin of modern human behavior. J. Hum. Evol. 39, 453–563. ( 10.1006/jhev.2000.0435) [DOI] [PubMed] [Google Scholar]

- 2.Van Peer P, et al. 2003. The Early to Middle Stone Age transition and the emergence of modern human behaviour at site 8-B-11, Sai Island, Sudan. J. Hum. Evol. 45, 187–193. ( 10.1016/S0047-2484(03)00103-9) [DOI] [PubMed] [Google Scholar]

- 3.de Beaune SA. 2004. The invention of technology. Curr. Anthropol. 45, 139–162. ( 10.1086/381045) [DOI] [Google Scholar]

- 4.Mercader J, Barton H, Gillespie J, Harris J, Khun S, Tyler R, Boesch C. 2007. 4,300-year-old chimpanzee sites and the origins of percussive stone technology. Proc. Natl Acad. Sci. USA 104, 3042–3048. ( 10.1073/pnas.0607909104) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Carvalho S, Cunha E, Sousa C, Matsuzawa T. 2008. Chaînes opératoires and resource-exploitation strategies in chimpanzee (Pan troglodytes) nut cracking. J. Hum. Evol. 55, 148–163. ( 10.1016/j.jhevol.2008.02.005) [DOI] [PubMed] [Google Scholar]

- 6.Haslam M, et al. 2009. Primate archaeology. Nature 460, 339–344. ( 10.1038/nature08188) [DOI] [PubMed] [Google Scholar]

- 7.McGrew W. 2010. In search of the last common ancestor: new findings on wild chimpanzees. Phil. Trans. R. Soc. B 365, 3267–3276. ( 10.1098/rstb.2010.0067) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Bril B, Smaers J, Steele J, Rein R, Nonaka T, Dietrich G, Biryukova E, Hirata S, Roux V. 2012. Functional mastery of percussive technology in nut-cracking and stone-flaking actions: experimental comparison and implications for the evolution of the human brain. Phil. Trans. R. Soc. B 367, 59–74. ( 10.1098/rstb.2011.0147) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.d'Errico F, Vanhaeren M, Henshilwood C, Lawson G, Maureille B, Gambier D, Tillier A, Soressi M, van Niekerk K. 2009. From the origin of language to the diversification of languages: what can archaeology and palaeoanthropology say? In Becoming eloquent: advances in the emergence of language, human cognition, and modern cultures (eds d'Errico F, Hombert JM), pp. 13–68. Amsterdam, The Netherlands: Benjamins. [Google Scholar]

- 10.d'Errico F, Stringer CB. 2011. Evolution, revolution or saltation scenario for the emergence of modern cultures? Phil. Trans. R. Soc. B 366, 1060–1069. ( 10.1098/rstb.2010.0340) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.de la Torre I, Benito-Calvo A, Arroyo A, Zupancich A, Proffitt T. 2013. Experimental protocols for the study of battered stone anvils from Olduvai Gorge (Tanzania). J. Archaeol. Sci. 40, 313–332. ( 10.1016/j.jas.2012.08.007) [DOI] [Google Scholar]

- 12.Visalberghi E, Haslam M, Spagnoletti N, Fragaszy D. 2013. Use of stone hammer tools and anvils by bearded capuchin monkeys over time and space: construction of an archaeological record of tool use. J. Archaeol. Sci. 40, 3222–3232. ( 10.1016/j.jas.2013.03.021) [DOI] [Google Scholar]

- 13.Whiten A. 2015. Experimental studies illuminate the cultural transmission of percussive technologies in Homo and Pan. Phil. Trans. R. Soc. B 370, 20140359 ( 10.1098/rstb.2014.0359) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Leroi-Gourhan A. 1971. L'Homme et la matière, 2nd edn Paris, France: Albin Michel. [Google Scholar]

- 15.Bril B. 1984. Description des gestes techniques: quelles méthodes? Tech. Cult. 3, 81–96. [Google Scholar]

- 16.Bril B. 1993. Les gestes de percussion: analyse d'un mouvement technique. In Savoir faire et pouvoir transmettre (ed. Chevallier D.), pp. 61–80. Paris, France: Editions de la Maison des sciences de l'homme. [Google Scholar]

- 17.Bril B, Dietrich G, Foucart J, Fuwa K. 2009. Tool use as a way to assess cognition: how do captive chimpanzees handle the weight of the hammer when cracking a nut? Anim. Cogn. 12, 217–235. ( 10.1007/s10071-008-0184-x) [DOI] [PubMed] [Google Scholar]

- 18.Bril B, Parry R, Dietrich G. 2015. How similar are nut-cracking and stone-flaking? A functional approach to percussive technology. Phil. Trans. R. Soc. B 370, 20140355 ( 10.1098/rstb.2014.0355) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Leakey MD. 1971. Olduvai Gorge, vol. 3. Excavations in Beds I and II, 1960–1963. Cambridge, UK: Cambridge University Press. [Google Scholar]

- 20.Willoughby PR. 1987. Spheroid and battered stones in the African Early and Middle Stone Age. Oxford, UK: British Archaeological Reports. [Google Scholar]

- 21.Goren-Inbar N, Sharon G, Melamed Y, Kislev M. 2002. Nuts, nut cracking, and pitted stones at Gesher Benot Ya'aqov, Israel. Proc. Natl Acad. Sci. USA 99, 2455–2460. ( 10.1073/pnas.032570499) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Mora R, de la Torre I. 2005. Percussion tools in Olduvai Beds I and II (Tanzania): implications for early human activities. J. Anthropol. Archaeol. 24, 179–182. ( 10.1016/j.jaa.2004.12.001) [DOI] [Google Scholar]

- 23.Barsky D, Vergès J-M, Sala R, Menéndez L, Toro-Moyano I. 2015. Limestone percussion tools from the late Early Pleistocene sites of Barranco León and Fuente Nueva 3 (Orce, Spain). Phil. Trans. R. Soc. B 370, 20140352 ( 10.1098/rstb.2014.0352) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Goren-Inbar N, Sharon G, Alperson-Afil N, Herzlinger G. 2015. A new type of anvil in the Acheulian of Gesher Benot Ya‘aqov, Israel. Phil. Trans. R. Soc. B 370, 20140353 ( 10.1098/rstb.2014.0353) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 25.Klein RG. 2009. The human career: human biological and cultural origin, 3rd edn Chicago, IL: University of Chicago Press. [Google Scholar]

- 26.Henshilwood CS, d'Errico F, van Niekerk KL, Coquinot Y, Jacobs Z, Lauritzen S-E, Garcia-Moreno R. 2011. A 100,000-year-old ochre-processing workshop at Blombos Cave, South Africa. Science 334, 219–222. ( 10.1126/science.1211535) [DOI] [PubMed] [Google Scholar]

- 27.Hillman GC. 1985. Traditional husbandry and processing archaic cereals in recent times. Part 1: the glume wheats. Bull. Sumerian Agric. 1, 114–152. [Google Scholar]

- 28.Stahl A. 1989. Plant-food processing: implications for dietary quality. In Foraging and farming. the evolution of plant exploitation (eds Harris DR, Hillman GC), pp. 171–194. London, UK: Unwin Hyman. [Google Scholar]

- 29.Wright K. 1992. Ground stone assemblages variation and subsistence strategies in the Levant, 22 000–5 500 BP. PhD thesis. New Haven, CT: Yale University. [Google Scholar]

- 30.Moore AMT, Hillman GC, Legge AJ. 2000. Village on the Euphrates. From foraging to farming at Abu Hureyra. New York: Oxford University Press. [Google Scholar]

- 31.Piperno DR, Weiss E, Holst I, Nadel D. 2004. Processing of wild cereal grains in the Upper Palaeolithic revealed by starch grain analysis. Nature 430, 670–673. ( 10.1038/nature02734) [DOI] [PubMed] [Google Scholar]

- 32.Flannery K. 1969. Origins and ecological effects of early domestication in Iran and Near East. In The domestication and exploitation of plants and animals (eds Ucko P, Dimbleby GW), pp. 23–53. Chicago, IL: Aldine. [Google Scholar]

- 33.Flannery K. 1973. The origins of agriculture. Annu. Rev. Anthropol. 2, 271–310. ( 10.1146/annurev.an.02.100173.001415) [DOI] [Google Scholar]

- 34.Stahl A. 1984. Hominid dietary selection before fire. Curr. Anthropol. 25, 151–168. ( 10.1086/203106) [DOI] [Google Scholar]

- 35.Stahl A. 1989. Plant-food processing: implications for dietary quality. In Foraging and farming: the evolution of plant exploitation (eds Harris DR, Hillman GC), pp. 171–194. London, UK: Unwin Hyman. [Google Scholar]

- 36.Liu L, Bestel S, Shi J, Song Y, Chen X. 2013. Paleolithic human exploitation of plant foods during the last glacial maximum in North China. Proc. Natl Acad. Sci. USA 110, 5380–5385. ( 10.1073/pnas.1217864110) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Hayden B, Canuel N, Shanse J. 2013. What was brewing in the Natufian? An archaeological assessment of brewing technology in the Epipaleolithic. J. Archaeol. Method Theory 20, 102–150. ( 10.1007/s10816-011-9127-y) [DOI] [Google Scholar]

- 38.Belfer-Cohen A, Goring-Morris N. 2011. Becoming farmers: the inside story. Curr. Anthropol. 52, S209–S220. ( 10.1086/658861) [DOI] [Google Scholar]

- 39.Zohary D, Hopf M, Weiss H. 2012. Domestication of plants in the Old World, 4th edn. Oxford, UK: Clarendon Press. [Google Scholar]

- 40.Willcox G. 2012. Searching for the origins of arable weeds in the Near East. Veg. Hist. Archaeobot. 21, 163–167. ( 10.1007/s00334-011-0307-1) [DOI] [Google Scholar]

- 41.Nadel D, Piperno DR, Holst I, Snir A, Weiss E. 2012. New evidence for the processing of wild cereal grains at Ohalo II, a 23 000-year-old campsite on the shore of the Sea of Galilee, Israel. Antiquity 86, 990–1003. ( 10.1017/S0003598X00048201) [DOI] [Google Scholar]

- 42.Kislev ME, Nadel D, Carmi I. 1992. Epi-Palaeolithic (19,000 BP) cereal and fruit diet at Ohalo II, Sea of Galilee, Israel. Rev. Palaeobot. Palynol. 71, 161–166. ( 10.1016/0034-6667(92)90054-K) [DOI] [Google Scholar]

- 43.Simchoni O. 1998. Reconstruction of the landscape and human economy 19,000 BP in the Upper Jordan Valley by the botanical remains found at Ohalo. PhD thesis Ramat Gan, Israel: Bar Ilan University. [Google Scholar]

- 44.Weiss E. 2002. Reconstruction of the human economy and society of the Epipalaeolithic site Ohalo II inhabitants by the macrofossil botanical remains. PhD thesis Ramat-Gan, Israel: Bar-Ilan University. [Google Scholar]

- 45.Nadel D. 2004. Wild barley harvesting, fishing, and year-round occupation at Ohalo II (19.5 KY, Jordan Valley, Israel). In Acts of the XIVth UISSP Congress, University of Liege, September 2001 (ed. S.T.U.P.G.S.a.P. Le Secrétariat du Congrès), pp. 135–143. Oxford, UK: BAR International Series 1240. [Google Scholar]

- 46.Weiss E, Kislev ME, Simchoni O, Nadel D, Tschauner H. 2008. Plant-food preparation area on an Upper Paleolithic brush hut floor at Ohalo II, Israel. J. Archaeol. Sci. 35, 2400–2414. ( 10.1016/j.jas.2008.03.012) [DOI] [Google Scholar]

- 47.Nadel D, Carmi I, Segal D. 1995. Radiocarbon dating of Ohalo II: archaeological and methodological implications. J. Archaeol. Sci. 22, 811–822. ( 10.1016/0305-4403(95)90010-1) [DOI] [Google Scholar]

- 48.Nadel D. 2002. Ohalo II—a 23,000 year-old fisher-hunter-gatherers’ camp on the shore of the Sea of Galilee (English/Hebrew). Haifa, Israel: Hecht Museum. [Google Scholar]

- 49.Belitzky S, Nadel D. 2001. Late Pleistocene and recent tectonic deformations at the Ohalo II prehistoric site (19 K) and the evolution of the Jordan River outlet from the Sea of Galilee. Geoarchaeology 17, 453–464. ( 10.1002/gea.10022) [DOI] [Google Scholar]

- 50.Tsatskin A, Nadel D. 2003. Formation processes at the Ohalo II submerged prehistoric campsite, Israel, deduced from soil micromorphology and magnetic susceptibility studies. Geoarchaeology 18, 409–432. ( 10.1002/gea.10069) [DOI] [Google Scholar]

- 51.Nadel D, Werker E. 1999. The oldest ever brush hut plant remains from Ohalo II, Jordan Valley, Israel (19 BP). Antiquity 73, 755–764. [Google Scholar]

- 52.Nadel D, Weiss H, Simchoni O, Tsatskin A, Danin A, Kislev ME. 2004. Stone age hut in Israel yields world's oldest evidence of bedding. Proc. Natl Acad. Sci. USA 101, 6821–6826. ( 10.1073/pnas.0308557101) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 53.Weiss E, Wetterstrom W, Nadel D, Bar-Yosef O. 2004. The broad spectrum revisited: evidence from plant remains. Proc. Natl Acad. Sci. USA 101, 9551–9555. ( 10.1073/pnas.0402362101) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Snir A, Nadel D, Weiss E. 2015. Plant-food preparation on two consecutive floors at Upper Paleolithic Ohalo II, Israel. J. Archaeol. Sci. 53, 61–71. ( 10.1016/j.jas.2014.09.023) [DOI] [Google Scholar]

- 55.Rots V, Williamson BS. 2004. Microwear and residue analyses in perspective: the contribution of ethnoarchaeological evidence. J. Archaeol. Sci. 31, 1287–1299. ( 10.1016/j.jas.2004.02.009) [DOI] [Google Scholar]

- 56.Shizhu W, Ping H. 2012. Principles of tribology. Singapore: John Wiley & Sons. [Google Scholar]

- 57.Bahadur S. 2012. Wear: a synoptic view. In Handbook of lubrication and tribology (ed. Totten G.), pp. 6/1–6/90. Boca Raton, FL: Taylor & Francis. [Google Scholar]

- 58.Semenov SA. 1964. Prehistoric technology: an experimental study of the oldest tools and artefacts from traces of manufacture and wear, p. 211 London, UK: Adams & Mackay. [Google Scholar]

- 59.Marreiros J, Gibaja J, Bicho N. 2015. Use-wear handbook. London, UK: Springer. [Google Scholar]

- 60.Keeley LH. 1980. Experimental determination of stone tool uses. Chicago, IL: University of Chicago Press. [Google Scholar]

- 61.Plisson H, Mauger M. 1988. Chemical and mechanical alteration of microwear polishes: an experimental approach. Helinium XXVIII, 3–16. [Google Scholar]

- 62.Dubreuil L, Grosman L. 2009. Ochre and hide-working at a Natufian burial place. Antiquity 83, 935–954. ( 10.1017/S0003598X00099269) [DOI] [Google Scholar]

- 63.Dubreuil L. 2004. Long-term trends in Natufian subsistence: a use-wear analysis of ground stone tools. J. Archaeol. Sci. 31, 1613–1629. ( 10.1016/j.jas.2004.04.003) [DOI] [Google Scholar]

- 64.Dubreuil L, Grosman L. 2013. The life history of macrolithic tools at Hilazon Tachtit Cave. In Natufian foragers in the Levant (eds Bar-Yosef O, Valla F), pp. 527–543. Ann Arbor, MI: International Monographs in Prehistory. [Google Scholar]

- 65.Dubreuil L, Savage D. 2014. Ground stones: a synthesis of the use-wear approach. J. Archaeol. Sci. 48, 139–153. ( 10.1016/j.jas.2013.06.023) [DOI] [Google Scholar]

- 66.Dubreuil L, Plisson H. 2010. Natufian flint versus ground stone tools: a use-wear perspective on subsistence change. Eurasian Prehist. 7, 45–60. [Google Scholar]

- 67.Dubreuil L, Savage D, Delgado S, Plisson H, Stephenson B, de la Torre I. 2015. Use-wear analysis of ground stone tools: discussing our current framework. In Use-wear handbook (eds Marreiros J, Bicho J), pp. 105–158. Berlin, Germany: Springer. [Google Scholar]

- 68.Fullagar R, Field J. 1997. Pleistocene seed-grinding implements from the Australian arid zone. Antiquity 71, 300–307. [Google Scholar]

- 69.Adams J, Delgado S, Dubreuil L, Hamon C, Plisson H, Risch R. 2009. Functional analysis of macro-lithic artifacts. In Non-flint raw material use in prehistory: old prejudices and new directions (eds Sternke F, Costa LJ, Eigeland L), pp. 43–66. Oxford, UK: Archaeopress. [Google Scholar]

- 70.Spivak P. 2008. The limestone and basalt assemblage from the Epipaleolithic site of Ohalo II, a 23,000 years old fisher-hunter-gatherers’ camp. MA thesis. Haifa, Israel: University of Haifa.

- 71.Procopiou H. 1998. L'outillage de mouture et de broyage en Crête Minoenne. PhD thesis Paris, France: Université de Paris I - Sorbonne. [Google Scholar]

- 72.Adams J. 2002. Ground stone analysis: a technological approach. Salt Lake City, UT: University of Utah Press. [Google Scholar]

- 73.Hamon C. 2007. Functional analysis of stone grinding and polishing tools from the earliest Neolithic of north-western Europe. J. Archaeol. Sci. 36, 1502–1520. [Google Scholar]

- 74.Delgado S. 2008. Practicas economicas y gestion social de recursos (macro)liticos en la prehistoria reciente (III-I Milenios AC) del mediterraneo occidental. PhD thesis Barcelona, Spain: Universitat de Barcelona. [Google Scholar]

- 75.Delgado Raack S, Gomez-Gras D, Risch R. 2009. The mechanical properties of macrolithic artifacts: a methodological background for functional analysis. J. Archaeol. Sci. 36, 1823–1831. ( 10.1016/j.jas.2009.03.033) [DOI] [Google Scholar]

- 76.Bofill M. 2012. Quantitative analysis of use-wear patterns: a functional approach to study grinding stone tools. In Broadening Horizons 3, Conference of young researchers working in the Ancient Near East, pp. 63–84. Barcelona, Spain: Universitat Autonoma de Barcelona. [Google Scholar]

- 77.Jones PR. 1994. Results of experimental work in relation to the stone industries of Olduvai Gorge. In Olduvai Gorge, vol. 5. Excavations in Beds III, IV and the Masek Beds, 1968–1971 (eds Leakey MD, Roe DA), pp. 254–298. Cambridge, UK: Cambridge University Press. [Google Scholar]

- 78.Roda Gilabert X, Martinez-Moreno J, Mora Torcal R. 2012. Pitted stone cobbles in the Mesolithic site of Font del Ros (Southeastern Pre-Pyrenees, Spain): some experimental remarks around a controversial tool type. J. Archaeol. Sci. 39, 1587–1598. ( 10.1016/j.jas.2011.12.017) [DOI] [Google Scholar]

- 79.Gilabert XR, Mora R, Martínez-Moreno J. 2015. Identifying bipolar knapping in the Mesolithic site of Font del Ros (northeast Iberia). Phil. Trans. R. Soc. B 370, 20140354 ( 10.1098/rstb.2014.0354) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 80.Bofill M, Taha B. 2013. Experimental approach to hide-processing task combining the use of bone and basalt tools: the Neolithic case of Tell Halula (Middle Euphrates Valley, Syria). In Experimentacion in arqueologia (eds Palomo R, Piqué R, Terradas X), pp. 45–55. Girona, Spain: Serie Monografica del MAC. [Google Scholar]

- 81.Wright K. 1992. A classification system for ground stone tools from the prehistoric Levant. Paléorient 18, 53–81. ( 10.3406/paleo.1992.4573) [DOI] [Google Scholar]

- 82.Bocquentin F, et al. 2014. Renewed excavations at Beisamoun: investigating the 7th millennium cal. BC of the Southern Levant. J. Isr. Prehist. Soc. 44, 5–99. [Google Scholar]

- 83.Wright K. 2014. Domestication and inequality? Households, corporate groups and food processing tools at Neolithic Çatalhöyük. J. Anthropol. Archaeol. 33, 1–33. ( 10.1016/j.jaa.2013.09.007) [DOI] [Google Scholar]

- 84.Chapman J. 2000. Fragmentation in archaeology. London, UK: Routledge. [Google Scholar]

- 85.Chapman J, Gaydarska B. 2007. Part and wholes: fragmentation in prehistoric context. Oxford, UK: Oxbow. [Google Scholar]

- 86.Adams J. 2008. Beyond the broken. In New approaches to old stones (eds Rowan Y, Ebeling J), pp. 213–229. London, UK: Equinox. [Google Scholar]

- 87.van Gijn A, Verbaas A. 2009. Reconstructing the life history of querns: the case of the LBK site in Geleen-Janskamperveld (NL). In Recent functional studies on non-flint stone tools: methodlogical improvements and archaeological inferences (eds de Araujo Igreja M, Conte IC). Lisboa, Portugal: Ministero della Cultura Portoghese. [Google Scholar]

- 88.Stroulia A, Chondrou D. 2013. Destroying the means of production. The case of ground stone tools from Kremasti-Kilada, Greece. In Destruction: archaeological, philological and historical perspectives (ed. Driessen J.), pp. 100–150. Louvain, Belgium: Presses Universitaires de Louvain. [Google Scholar]

- 89.Watts S. 2014. The life and death of querns. Oxford, UK: Oxbow. [Google Scholar]

- 90.Lemonier P. 2008. Postface: la mort, le mort et les autres: remarques d'anthropologue. Prehist. Méditerr. 14, 209–214. [Google Scholar]

- 91.Nadel D. 2011. Stones in their symbolic context: Epipalaeolithic – pre-pottery Neolithic continuity in the Jordan Valley. In The state of the stone. Terminologies, continuities and contexts in Near Eastern Lithics (eds Healey E, Campbell S, Maeda O), pp. 481–490. Berlin, Germany: ex oriente. [Google Scholar]

- 92.Nadel D. 2003. A long continuity: the Ohalo II brush huts (19.5 ky) and the dwelling structures in the Natufian and PPNA sites in the Jordan Valley. Archaeol. Anthropol. Ethnol. Euroasia 13, 34–48. [Google Scholar]

- 93.Maher L, Richter T, Stock J. 2012. The pre-Natufian Epipaleolithic: long-term behavioral trends in the Levant. Evol. Anthropol. 21, 69–81. ( 10.1002/evan.21307) [DOI] [PubMed] [Google Scholar]

- 94.Bar-Yosef O. 1980. Prehistory of the Levant. Annu. Rev. Anthropol. 9, 101–133. ( 10.1146/annurev.an.09.100180.000533) [DOI] [Google Scholar]

- 95.Bar-Yosef O, Belfer-Cohen A. 1989. The origins of sedentism and farming communities in the Levant. J. World Prehist. 3, 447–498. ( 10.1007/BF00975111) [DOI] [Google Scholar]

- 96.Dubreuil L. 2002. Etude fonctionnelle des outils de broyage natoufiens: nouvelles perspectives sur l’émergence de l’agriculture au Proche-Orient. PhD thesis Talence, France: Université de Bordeaux 1. [Google Scholar]

- 97.Eitam D. 2010. Late Epipaleolithic rock-cut installations and groundstone tools in the Southern Levant. Paléorient 35, 77–104. ( 10.3406/paleo.2009.5279) [DOI] [Google Scholar]

- 98.Rosenberg D, Nadel D. 2014. The sounds of pounding: boulder mortars and their significance to Natufian burial customs. Curr. Anthropol. 55, 784–812. ( 10.1086/679287) [DOI] [Google Scholar]

- 99.Revedin A, et al. 2010. Thirty thousand-year-old evidence of plan food processing. Proc. Natl Acad. Sci. USA 10, 18 815– 18 819 ( 10.1073/pnas.1006993107) [DOI] [PMC free article] [PubMed] [Google Scholar]

- 100.Revedin A, et al. 2014. New technologies for plant food processing in the Gravettian. Quat. Int. 359–360, 77–88. [Google Scholar]

- 101.Smith B. 2011. A cultural niche construction theory of initial domestication. Biol. Theory 6, 260–271. ( 10.1007/s13752-012-0028-4) [DOI] [Google Scholar]

- 102.Gremillion K, Barton L, Piperno D. 2014. Particularism and the retreat from theory in the archaeology of agricultural origins. Proc. Natl Acad. Sci. USA 111, 6171–6177. ( 10.1073/pnas.1308938110) [DOI] [PMC free article] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary figures

Data Availability Statement

The datasets supporting this article have been uploaded as part of the electronic supplementary material.