Rubberwood | The Wood Database (Hardwood) (original) (raw)

Rubberwood (Hevea brasiliensis) Rubberwood (Hevea brasiliensis)  |

Common Name(s): Rubberwood, plantation hardwood, parawood, Malaysian oak Scientific Name: Hevea brasiliensis Distribution: Native to Brazil, but extensively cultivated in tropical regions, especially in Asia Tree Size: 75-100 ft (23-30 m) tall, 1-3 ft (.3-1 m) trunk diameter Average Dried Weight: 37 lbs/ft3 (595 kg/m3) Specific Gravity (Basic, 12% MC): .49, .59 Janka Hardness: 960 lbf (4,280 N) Modulus of Rupture: 10,420 lbf/in2 (71.9 MPa) Elastic Modulus: 1,314,000lbf/in2 (9.07 GPa) Crushing Strength: 6,110 lbf/in2 (42.1 MPa) Shrinkage: Radial: 2.3%, Tangential: 5.1%, Volumetric: 7.5%, T/R Ratio: 2.2 |

|---|

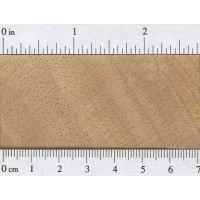

Color/Appearance: Heartwood naturally a light blonde to medium tan color, sometimes with medium brown streaks. Sapwood not distinct from heartwood. Color tends to darken slightly with age. Frequently colored or stained when used in furniture construction.

Grain/Texture: Grain is straight, with a somewhat coarse, open texture. Low natural luster.

Endgrain: Diffuse-porous; large to very large pores in no specific arrangement, very few; solitary and radial multiples and rows of 2-4; tyloses and heartwood mineral/gum deposits (brown) occasionally present; growth rings usually indistinct; narrow to medium rays barely visible without lens, normal spacing; parenchyma diffuse-in-aggregates and banded (reticulate).

Rot Resistance: Rubberwood is perishable, and has very little natural resistance to decay. It is also susceptible to fungal staining and insect attacks.

Workability: Easy to work with both hand and machine tools. Rubberwood tends to warp and twist in drying, though it is fairly stable in service once seasoned. Glues, stains, and finishes well.

Odor: Rubberwood has an unpleasant sour odor while being worked, especially when green, which subsides upon drying.

Allergies/Toxicity: Besides the standard health risks associated with any type of wood dust, no further health reactions have been associated with rubberwood in particular. However, individuals with natural latex or rubber allergies may have reactions to rubberwood. See the articles Wood Allergies and Toxicity and Wood Dust Safety for more information.

Pricing/Availability: Rubberwood is rarely exported in raw lumber form, but is instead worked into a variety of furniture, kitchen, and other household items and then exported and sold elsewhere.

Sustainability: This wood species is not listed in the CITES Appendices or on the IUCN Red List of Threatened Species. Rubberwood lumber is typically taken from rubber plantations where the trees are tapped for latex, and harvested at the end of their useful life cycle—typically after about thirty years.

Common Uses: Furniture, cabinetry, interior millwork, kitchen woodenware (cutting boards, knife blocks, etc.), and other small, specialty wood items.

Comments: Despite its common name, rubberwood isn’t any more elastic or soft than comparable hardwoods of similar density/weight—the name is derived from its use on rubber plantations, where the sap is harvested as a natural source of latex. Rubberwood is seen on a wide variety of (mostly inexpensive) Asian imported furniture. Many big-box and home furnishings retailers have pieces made of rubberwood. When sold in this capacity, the wood is sometimes marketed under ambiguous monikers such as plantation hardwood, or worse, Malaysian oak, though it is not related to true oak in the Quercus genus. The wood is commonly stained and available in a wide range of colors and finishes.

None available.

None available.

Scans/Pictures:

Rubberwood (sanded) Rubberwood (sanded) |

Rubberwood (sealed) Rubberwood (sealed) |

|---|---|

Rubberwood (endgrain) Rubberwood (endgrain) |

Rubberwood (endgrain 10x) Rubberwood (endgrain 10x) |

Rubberwood (chair) Rubberwood (chair) |