How AWT and SPC Worked | Glenn Research Center | NASA (original) (raw)

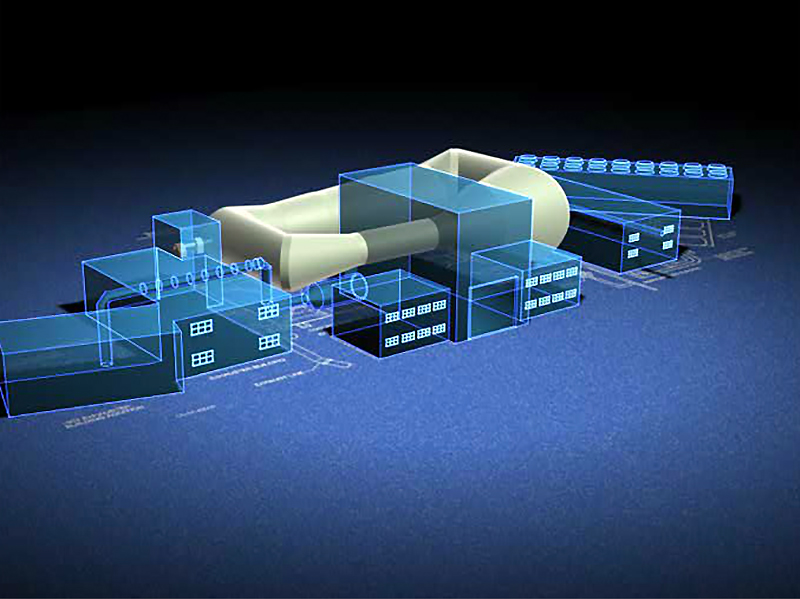

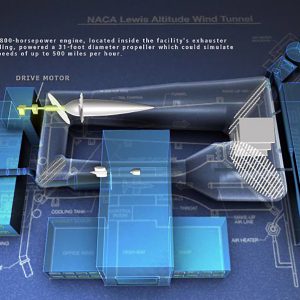

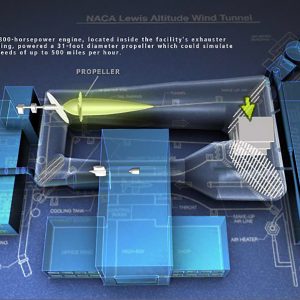

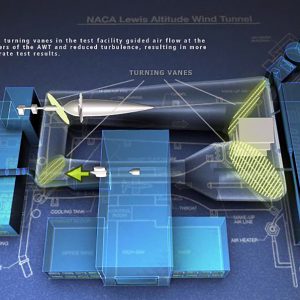

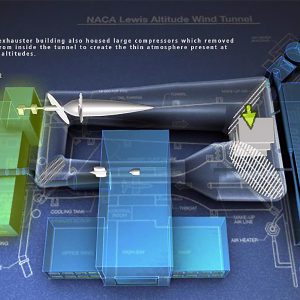

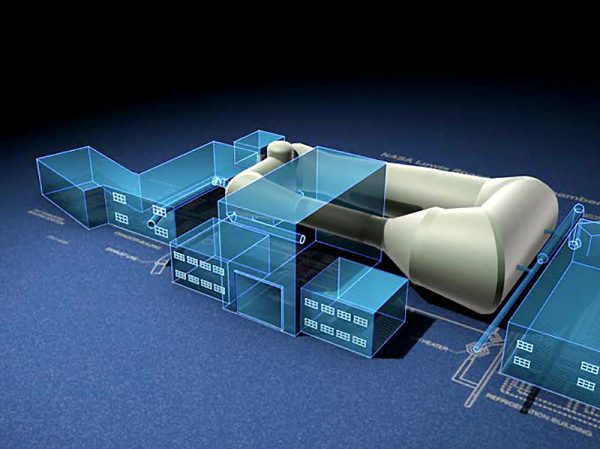

The AWT/SPC complex.

This page describes how the AWT and SPC No. 1 operated, gives overview of the development of wind tunnels and vacuum chambers, and defines terms related to these facilities.

Wind Tunnels Overview

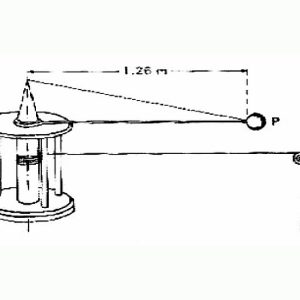

Almost as long as humans have contemplated air travel, they have sought to create flight conditions in a controlled environment to assist the design process. Today, computer-aided design and flight simulators can replicate flight conditions, but traditionally there were two basic methods for simulating flight with model aircraft on the ground—propelling an aircraft through the air or subjecting a stationary aircraft to an airflow. The earliest simulation tools in the mid-18th century used this first method. These “whirling arms” consisted of a pole with a model aircraft held on an extended arm. The arm was then rotated rapidly in circles to simulate actual flight.

The second, and most successful, form of testing was the placement of a stationary model inside a tunnel. Flight was simulated when air was pulled through the tunnel and past the model aircraft. The tunnel method proved to be more practical and efficient than the whirling arms. The tunnel operator can control wind speed and other atmospheric conditions, as well as the aircraft’s angle of attack and attitude. Although there are full-scale wind tunnels in existence, most are not large enough to accommodate an actual aircraft. Instead, scaled-down models, which are comparatively inexpensive and easy to modify, are used.

Documents

- Wind Tunnel Resources

- Beginner’s Guide to Wind Tunnels

- Wind Tunnels of NASA (SP-440)

- NASA Glenn’s Current Wind Tunnels

Diagram of early “whirling arm” device used to test aircraft models.

Replica of a wind tunnel designed and used by the Wright Brothers between 1901 and 1903.

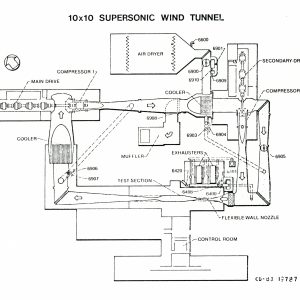

Open loop wind tunnel. The original configuration of the 8-by 6-Foot Supersonic Wind Tunnel.

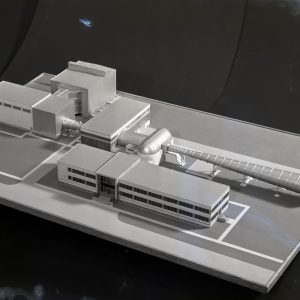

Closed loop tunnel. Glenn’s 10-by 10-Foot Supersonic Wind Tunnel.

How the AWT Worked

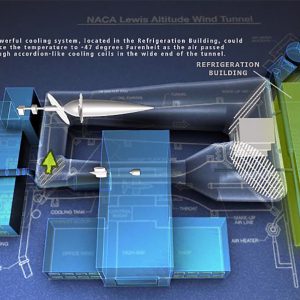

The NASA Glenn Research Center’s Altitude Wind Tunnel (AWT) was capable of testing full-scale aircraft engines and creating airspeeds, altitude, and air quality conditions experienced during actual flight. [1] An 18,000-horsepower engine [2] located in the facility’s Exhauster Building powered a 31-foot-diameter propeller [3] that would simulate airspeeds up to 500 miles per hour. The Exhauster Building also contained large compressors [4], which removed air from inside the tunnel to create the thin atmosphere present at high altitudes. Also, turning vanes [5] guided airflow in the corners of the AWT and reduced turbulence, resulting in more accurate test results.

Documents

Drive motor.

Fan.

Turning vanes.

Exhausters.

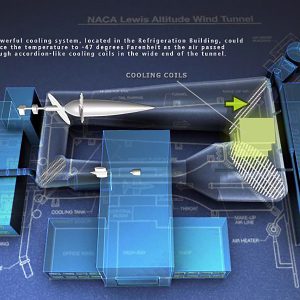

A powerful cooling system located in the Refrigeration Building [6] could reduce the tunnel’s temperature to –47 °F as the air passed through accordion-like cooling coils [7] at the wide end of the tunnel. Fresh air was introduced into the wind stream [8] prior to the test section.

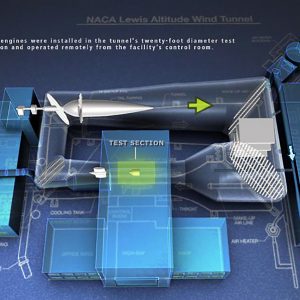

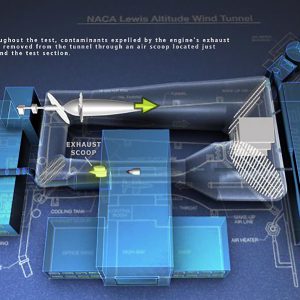

The engine being tested was installed in the 20-foot-diameter test section [9] and operated remotely from the facility’s control room. Numerous instrumentation devices in the facility’s control room [10] recorded the tunnel conditions and engine performance during the tests. Throughout the test, contaminants expelled by the engine’s exhaust were remove from the tunnel through an airscoop [11] located just beyond the test section.

Refrigeration Building.

Cooling coils.

Test section.

Air scoop.

Wind Tunnel Terminology

Closed-Loop Tunnel: The closed-loop tunnel is usually square shaped. It recycles airflow so it is more efficient. The closed-loop tunnel is more expensive to build and requires a larger area. Sets of turning vanes are placed in the corners to guide the airflow through the wind tunnel loop. The AWT was a closed-loop tunnel.

Contraction: Section prior to the test section where the tunnel narrows to increase the speed of the airflow through the test section. It is sometimes referred to as the throat section. The AWT contracts from 51 to 20 feet in diameter.

Diffuser: Area past the test section where the tunnel’s diameter widens so that the airspeed is slowed down.

Drive: The apparatus that forces air through the tunnel. It is usually a large fan that is powered by a powerful motor. The AWT had a 31-foot-diameter fan spun by an 18,000-horsepower motor.

Open-Loop Tunnel: Wind tunnels are generally either open- or closed-loop designs. The open-loop type is a simple design that consists of a long open-ended tube. A fan at the far end of the tunnel pulls the air through the tunnel, past the test section, and expels it out the far end of the tunnel. Open-loop tunnels are often inefficient to operate.

Pressure Tunnel: Small-scale test articles and the atmospheric airflow resulted in questionable test results due to the Reynolds number. By pressurizing the tunnel to altitudes corresponding to the size of the test article, actual flight conditions are simulated.

Reynolds Number: Early wind tunnel test results were often inaccurate since the airflow around the tunnel model and the actual flight were different. Osborne Reynolds (1842–1912) discovered that flow over a scale model would only be identical to the full-scale object if the Reynolds number was identical. The Reynolds number is a non-dimensional factor that indicates the ratio of the momentum to the viscosity in gas or liquid fluid flow. Basically, the Reynolds number expresses the relationship of the fluid density, velocity, the object’s size, and the coefficient of viscosity of the fluid relationship.

Settling Chamber: Section of a wind tunnel, usually just before the contraction, where the airflow is straightened and turbulence reduced. The AWT had a 51-foot-diameter settling chamber.

Test Section: Portion of a wind tunnel where the test article and sensors are placed. The AWT had a large 20-foot-diameter test section.

Space Power Chambers facility.

Vacuum Chamber Overview

The use of vacuum chambers to simulate high altitudes began during World War I. The air pressure decreases as altitude increases. By reducing the quantity of air in a chamber or tank, one can simulate the air pressures of high altitude. This was done for a variety of aeronautics uses, including studying engine behavior and the effect of altitude on pilots.

Initial space flights during the late 1950s and early 1960s showed the behavior of engines, flight systems, and hardware was affected by the vacuum and cold temperatures found in space. There was a need to test full-size versions of these items in a vacuum chamber before the mission. In the early 1960s there was a wave of large vacuum chambers built for this purpose.

How SPC No. 1 Worked

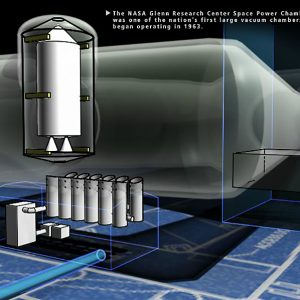

The NASA Glenn Research Center’ SPC No. 1 was one of the nation’s first vacuum chambers when it began operating in 1963. The chamber, capable of simulating conditions found at 100 miles altitude, allowed researcher to study and better understand space system behavior in a space environment.

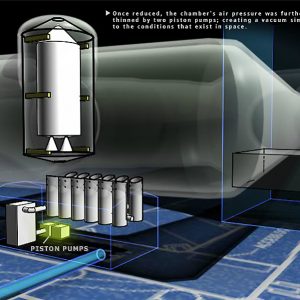

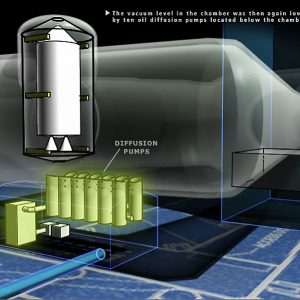

The center’s central air system, connected to the chamber, could reduce the chamber’s atmosphere to the equivalent of 100,000 feet above sea level [1]. Once reduced, the chamber’s air pressure was further thinned by two piston pumps, creating a vacuum similar to the conditions that exist in space [2]. The vacuum level in the chamber was then again lowered by 10 oil diffusion pumps located below the chamber [3].

Documents

SPC No. 1 overview.

Central air line.

Piston pumps.

Oil diffusion pumps.

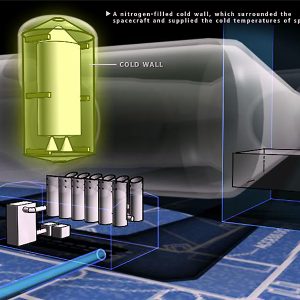

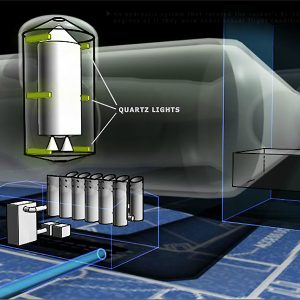

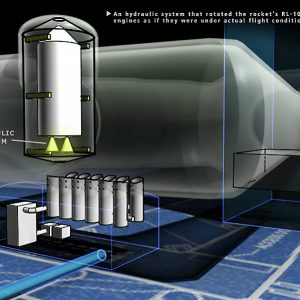

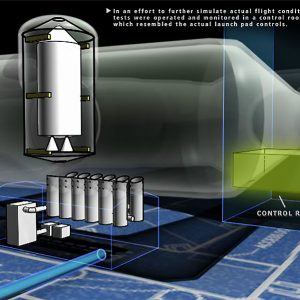

A complex setup in the chamber helped create all the conditions of space, with the exception of microgravity and meteors. The setup included a nitrogen-filled cold wall, which surrounded the spacecraft and supplied the cold temperatures of space [4]; six banks of quartz lights which provided solar radiation [5]; a hydraulic system rotated the rocket’s RL–10 engines as if they would in actual flight conditions [6]; a tanking system which maintained the balloon-like fuel tanks at partially-filled levels [7]; and a variety of instruments that monitored the equipment being tested and the conditions inside the test chamber. In an effort to further simulate actual flight conditions, tests were operated and monitored in a control room that resembled the actual launch pad controls [8].

Cold wall.

Heat lamps.

Hydraulic system.

SPC No. 1 control room.

Vacuum Chamber Terminology

Altitude: Considered the elevation above an acknowledged level. In aerospace situations, this level is usually mean sea level. Height is the elevation above a point on the ground.

Atmospheric Pressure: Pressure caused by the weight of the atmosphere. As the altitude increases, the atmospheric pressure decreases. At sea level it has a mean value of 1 atmosphere.

Cold Wall: A copper baffle, which has liquid-nitrogen-filled ribs and black interior that produced low temperatures found in outer space. The SPC No. 1 cold wall was 20 feet in diameter and 42 feet high and used a thermal siphon to draw cryogenic liquid nitrogen into the vertical ribs.

Space Tank: A chamber from which air is removed. The resulting vacuum is used to simulate the air pressure levels found in outer space. Space tanks, or vacuum chambers, often include other elements, such as cold walls, to further simulate the space environment.

Vacuum: A space entirely devoid of matter, including air. Outer space has a very low density, which is similar to a vacuum.

Vacuum Pump: A pump used to remove air from a space or tank. SPC No. 1 used several types of vacuum pumps. The diffusion pumps, which had no moving parts, directed residual molecules from the chamber using high-speed jets of fluid.