optical flats (original) (raw)

Definition: plates with one or two surfaces of very high optical quality and flatness

Categories:  general optics,

general optics,  optical metrology

optical metrology

- optical elements

- optical flats

- achromatic optics

- adaptive optics

- aspheric optics

- custom optics

- diffractive optics

- fiber optics

- flat optics

- large diameter optics

- laser optics

- nonlinear optics

- optical elements for imaging

- polarization optics

- refractive optical elements

- reflective optical elements

- beam splitters

- beam collimators

- beam expanders

- beam homogenizers

- diffusers

- group velocity delay compensation plates

- optical apertures

- optical attenuators

- optical filters

- optical modulators

- optical windows

- phase corrector plates

- (more topics)

Related: interferometersoptical materialsmirrors

Page views in 12 months: 549

DOI: 10.61835/7um Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

📦 For purchasing optical flats, use the RP Photonics Buyer's Guide — an expert-curated directory for finding all relevant suppliers, which also offers advanced purchasing assistance.

Contents

What are Optical Flats?

Optical flats are plates with one or two surfaces of particularly high optical quality and flatness. The degree of flatness is quantified by the distance between two parallel imaginary planes, where one is tangential to the highest point of the surface and the other one to the lowest point. That flatness deviation is normally specified as λ/10 or better (i.e., a smaller value), and sometimes even substantially better — e.g. down to a few nanometers. The surface roughness is also usually very low.

Application

Optical flats are mainly used as highly flat reference surfaces in interferometers for checking the flatness of optical elements such as optical windows, laser mirrors, prisms, optical filters or laser crystals. For example, one may place an optical flat close to an inspected surface, but slightly tilted against that surface, so that surfaces with ideal quality would result in a regular pattern of straight interference fringes when the assembly is illuminated with monochromatic light. Any deviations from that pattern then indicate deviations from perfect flatness.

Fabrication

Optical flats are fabricated in several steps, essentially in the same way as mirror substrates.

With further production steps, such as the application of a dielectric coating, optical flats also be turned into high-quality optical elements themselves. For example, a Twyman–Green interferometer requires a very flat reference mirror, which can be made from an optical flat.

For checking the quality of optical flats, one may inspect them in interferometers, ideally using an even better reference surface. In some cases, one uses reference surfaces based on a liquid like mercury, which can be extremely flat but is difficult to handle.

Types of Optical Flats

Typically, an optical flat has a cylindrical shape, a diameter of a couple of centimeters, a thickness of a few millimeters, and is made of fused silica or some other clear optical glass. It thus looks like a mirror substrate. However, different types of optical flats are available:

- Some of them are very large, with diameters of tens of centimeters, suitable for testing very large surfaces.

- Different optical materials can be used. Fused silica is very common, since it is mechanically quite hard and chemically stable, and it exhibits a relatively small coefficient of thermal expansion (0.55 · 10−6 K−1). However, one can also use glass ceramics (e.g. Zerodur) with even several times lower thermal expansion coefficients, if that is of interest. For testing infrared optics, for example, various other materials can be used, for example germanium, silicon, zinc selenide (ZnSe) and sapphire.

Different degrees of surface quality can be obtained. A typical flatness specification would be λ/10, but even higher qualities are available. Usually, the surface quality should be substantially better than the specifications of the objects to be tested, so that obtained deviations from flatness are largely dominated by the quality of those objects.

Handling of Optical Flats

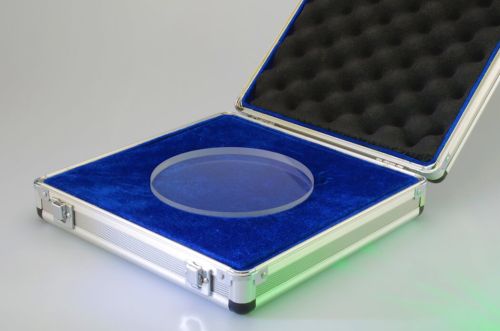

Even optical flats made from a robust material such as fused silica should be handled with great care to avoid any surface damage. For example, one should always store optical flats in a suitable box, in which it is wrapped in a soft material.

During interferometric measurements, both the optical flat and the tested surface should be very clean; see the article on cleaning of optics.

Frequently Asked Questions

This FAQ section was generated with AI based on the article content and has been reviewed by the article’s author (RP).

What is an optical flat?

An optical flat is an optical plate with one or two surfaces of exceptionally high flatness and low surface roughness. The flatness deviation is typically specified as λ/10 or better.

What are optical flats used for?

They primarily serve as highly flat reference surfaces in interferometers to check the flatness of other optical components. When placed near a test surface and illuminated with monochromatic light, the resulting interference pattern reveals any deviations from perfect flatness on the tested part.

What materials are used for optical flats?

Fused silica is common due to its hardness, chemical stability, and low thermal expansion. For even better thermal stability, glass ceramics like Zerodur are used. For infrared optics, materials like germanium, silicon, zinc selenide, or sapphire are employed.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 50 suppliers for optical flats. Among them:

⚙ hardware

Used as a reference surface, Knight Optical's optical flats are provided in single-or double-sided Zerodur and quartz varieties with λ/10 or λ/20 flatness available. Our stock catalogue includes 26 mm to 302 mm diameter optical flats which are packaged in a protective wooden box. Custom optical flats are also available with differing dimensions and flatness specifications. We also stock monochromatic light units which are used to view the fringe patterns on the surface of the optical flat when testing a surface.

⚙ hardware

Artifex Engineering offers precisely flat reference plates for optical testing. Our optical flats are available as single surface and dual surface options. We will gladly customize to your requirements. Additionally we offer standard optical flats in N-BK7 and fused silica. Visit our product page for more information. We look forward to your inquiry.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.