pyroelectric detectors (original) (raw)

Definition: light detectors based on the pyroelectric effect

Alternative term: pyroelectric energy sensor

Categories:  photonic devices,

photonic devices,  light detection and characterization

light detection and characterization

- photodetectors

- infrared detectors

- position-sensitive detectors

- photodiodes

- phototransistors

- metal–semiconductor–metal photodetectors

- velocity-matched photodetectors

- photomultipliers

- phototubes

- pyroelectric detectors

- photoconductive detectors

- photoemissive detectors

- solar-blind photodetectors

- single-photon detectors

- terahertz detectors

- velocity-matched photodetectors

- (more topics)

Related: optical energy metersthermal detectors

Page views in 12 months: 1886

DOI: 10.61835/l29 Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

📦 For purchasing pyroelectric detectors, use the RP Photonics Buyer's Guide — an expert-curated directory for finding all relevant suppliers, which also offers advanced purchasing assistance.

Contents

What are Pyroelectric Detectors?

Ferroelectric Crystal Materials

Response to Sound (Microphony)

Summary:

Pyroelectric detectors are thermal sensors used for detecting light, particularly infrared light pulses. They operate based on the pyroelectric effect, where a change in temperature in a ferroelectric crystal generates an electrical signal. This makes them ideal for measuring the energy of laser pulses but unsuitable for continuous-wave light.

The article details the operation principle, involving an absorbing coating and a compensating crystal to reduce noise from ambient temperature fluctuations. It also reviews common pyroelectric materials like triglycine sulfate (TGS), lead zirconate titanate (PZT), and lithium tantalate (LiTaO3), highlighting their respective properties such as Curie temperature and robustness.

Key performance parameters are also explained, including their characteristically broad spectral response, typical active area sizes, sensitivity, dynamic range for pulse energy measurements, and detection bandwidth. Potential issues like surface reflectivity and microphony (sensitivity to sound) are also addressed.

(This summary was generated with AI based on the article content and has been reviewed by the article’s author.)

What are Pyroelectric Detectors?

Pyroelectric detectors are sensors for light which are based on the pyroelectric effect. They are widely used for detecting laser pulses (rather than continuous-wave light), often in the infrared spectral region, and with the potential for a very broad spectral response. Pyroelectric detectors are used as the central parts of many optical energy meters, and are typically operated at room temperature (i.e., not cooled). Compared with energy meters based on photodiodes, they can have a much broader spectral response.

There are various other applications of pyroelectric sensors, for example fire detection, satellite-based infrared detection, and the detection of persons via their infrared emission (motion detectors).

Operation Principle

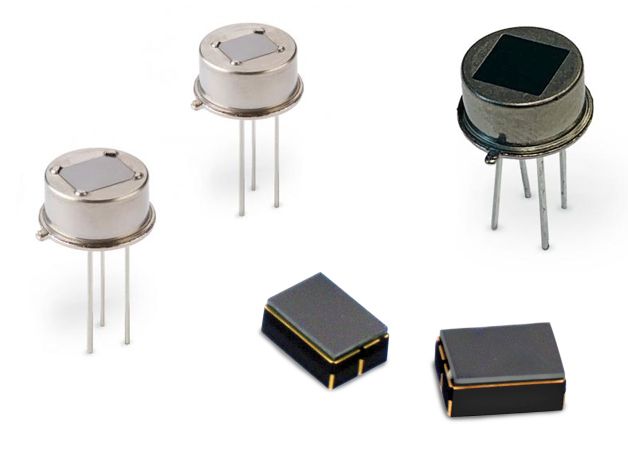

Figure 1: Pyroelectric detectors. Source: Excelitas Technologies

We first consider the basic operation principle. A pyroelectric detector contains a piece of ferroelectric crystal material with electrodes on two sides — essentially a capacitor. One of those electrodes has a black coating (or a processed absorbing metal surface), which is exposed to the incident radiation. The incident light is absorbed on the coating and thus also causes some heating of the crystal because the heat is conducted through the electrode into the crystal. As a result, the crystal produces some pyroelectric voltage; one can electronically detect that voltage or alternatively the current when the voltage is held constant. For a constant optical power, that pyroelectric signal would eventually fade away; the device would therefore not be suitable for measuring the intensity of continuous-wave radiation. Instead, such a detector is usually used with light pulses; in that case, one obtains a bipolar pulse structure, where one initially obtains a voltage in one direction and after the pulse a voltage in the opposite direction.

Due to that operation principle, pyroelectric detectors belong to the thermal detectors: they do not directly respond to radiation, but only to the generated heat.

In the simple form explained, the detector would be relatively sensitive to fluctuations in the ambient temperature. Therefore, one often uses an additional compensating crystal, which is exposed to essentially the same temperature fluctuations but not to the incoming light. By taking the difference of signals from both crystals, one can effectively reduce the sensitivity to external temperature changes.

The pyroelectric charges are typically detected with an operational amplifier (OpAmp) based on field-effect transistors (JFETs) with very low leakage current.

Ferroelectric Crystal Materials

Only a small group of crystals possesses a low enough crystal symmetry (e.g. monoclinic) for exhibiting ferroelectric properties and the pyroelectric effect. They have an electrical polarization which is temperature-dependent and thus leads to pyroelectric charges when the temperature changes.

A particularly high sensitivity is achieved when using triglycine sulfate (TGS, (NH2CH2COOH)3·H2SO4). That material, however, has a rather low Curie temperature of 49 °C; above that temperature, the ferroelectric properties vanish. A somewhat higher Curie temperature of 61 °C is obtained for modified form of that material, deuterated triglycine sulfate (DTGS). Both materials, however, are not acceptable for applications where one cannot ensure that one always stays sufficiently below the Curie temperature. Note also that the pyroelectric response is substantially increased just below the Curie temperature, so that the calibration is affected. Further, there is a risk of depoling at higher temperatures. In addition, TGS and DTGS are water-soluble, hygroscopic and fragile, therefore not well suited for robust optical energy meters.

Other ferroelectric materials, belonging to the perovskite group, are lead zirconate titanate (PZT, PbZrTiO3) and lead titanate (PT, PbTiO3). They need to be used in a ceramic form (e.g. as deposited thin films), since large crystals are hard to make; additional dopants are required for stability at room temperature. These materials can be produced at relatively low cost and are far more robust than TGS.

A material with very high Curie temperature and overall high robustness is lithium tantalate (LiTaO3), which is therefore often used despite its lower pyroelectric response.

Performance Parameters

Spectral Response

As usual for thermal detectors, the spectral response can be very broad; one only requires sufficiently broadband absorption.

A pyroelectric sensor may be equipped with an infrared filter which transmits only light in a certain range of wavelengths.

Active Area

The active area is usually a circular disk or a rectangular area with a diameter between a few millimeters and a few tens of millimeters. Tentatively, detectors for higher pulse energies have larger active areas.

Surface Reflectivity

In principle, a pyroelectric detector should ideally absorb all incident light for having a sensitivity as high as possible. However, for a fast response one wants to use a thin absorbing coating, which sits on a reflecting metallic electrode, or just a metallic electrode with processed surface structure for enhanced absorption. Therefore, there can be a substantial reflectivity (of the order of 50%) in practice.

Maximum Pulse Width

For such a detector to work properly, the input pulses need to be sufficiently short. The maximum allowed pulse width vary substantially between different models; it can be some tens of microseconds, for example. Pulses from a Q-switched laser are always short enough.

Sensitivity and Dynamic Range

Pyroelectric detectors are normally used for detecting pulses with pulse energies in the nanojoule or microjoule region. The most sensitive devices have a noise floor well below 100 pJ, so that even pulse energies of a few nanojoules can be measured with a reasonable accuracy. At the same time, pulse energies as high as 10 μJ may be allowed, so that one effectively has a dynamic range of e.g. 40 dB for energy measurements.

Other devices are optimized for much higher pulse energies of e.g. several joules, but have a higher noise floor, allowing measurements down to pulse energies of tens of microjoules instead of nanojoules.

Note that there may be a further limitation for the allowed average power. That means that for the highest possible pulse repetition rates, the pulse energy needs to be limited because otherwise there would be too strong heating of the sensor.

Detection Bandwidth

A typical detection bandwidth of a pyroelectric detector is several kilohertz, or sometimes even tens of kilohertz. This is quite fast compared with many other thermal detectors such as thermocouples and thermopiles, and is possible due to the small thermal capacity of the compact detector crystal. (The electrical capacity can in principle also be a limiting factor, but typically the thermal relaxation time is essential.) For a particularly fast response, one can use thin metallic electrodes with a processed absorbing surface, minimizing the thermal capacity.

Suppliers often specify instead of a true bandwidth the maximum allowed pulse repetition rate, where one can still measure the energy of each pulse. This is actually the quantity which is most relevant for users. One can use such a detector for monitoring pulse energy fluctuations in a Q-switched laser, for example. For measuring only the average pulse energy, one could simply use a slow thermal detector, which delivers the average power, and divide this by the pulse repetition rate.

The pulse repetition rate of a mode-locked laser would be far too high; here one would have to use a photodiode.

Response to Sound (Microphony)

All pyroelectric crystal materials are also piezoelectric. Therefore, a pyroelectric detective will also show some response to incoming sound waves, i.e., it acts as a microphone — which is normally unwanted. Such microphony can be suppressed e.g. with proper mounting and shielding of the crystal.

Frequently Asked Questions

This FAQ section was generated with AI based on the article content and has been reviewed by the article’s author (RP).

What is a pyroelectric detector?

A pyroelectric detector is a type of thermal sensor for light based on the pyroelectric effect. It is primarily used for detecting laser pulses, often in the infrared spectral region, and can operate at room temperature.

How does a pyroelectric detector work?

It contains a ferroelectric crystal that generates a voltage when its temperature changes. Incident light is absorbed by a coating, heating the crystal and producing a detectable electrical signal. The detector responds to changes in temperature, not to constant heat.

Why are pyroelectric detectors mainly used for light pulses?

Pyroelectric detectors respond to a change in temperature. A light pulse causes a rapid temperature increase and a corresponding signal. For continuous-wave light, the crystal temperature would stabilize, and the pyroelectric signal would fade away.

What are common materials for pyroelectric detectors?

Common materials include triglycine sulfate (TGS) for high sensitivity, lead zirconate titanate (PZT) for robustness and low cost, and lithium tantalate (LiTaO3) for a very high Curie temperature and overall high robustness.

What determines the spectral response of a pyroelectric detector?

As a thermal detector, its intrinsic spectral response is very broad. The practical response is determined by the absorption properties of its surface coating, which is designed to be a broadband absorber, often a black coating.

What is microphony in pyroelectric detectors?

Since pyroelectric materials are also piezoelectric, they can respond to sound waves and vibrations, acting like a microphone. This unwanted effect, called microphony, can be minimized with proper mounting and shielding of the detector crystal.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 12 suppliers for pyroelectric detectors. Among them:

⚙ hardware

AMS Technologies carries a broad variety of both digital and analog pyroelectric IR detectors (PIR), in single-, dual and quad element configurations, ideal for motion detection or gas detection in many application areas:

- single-element PIRs in TO-5 metal housing, analog or digital, single- or dual-channel, thermally compensated, for gas detection

- dual-element PIRs in TO-5, low-profile TO-39, or LCC SMD housings, analog or digital, for horizontal-mount motion detection devices, also over long distances

- four-element PIRs in TO-5 metal housing, analog or digital, single or dual output, for ceiling-mount short-, mid- and long-distance motion detection devices

- low-power digital dual- and four-element PIRs in TO-5 or LCC SMD housings, for battery-operated short-, mid- and long-distance motion detection

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.