quarter-wave mirrors (original) (raw)

Definition: dielectric mirrors based on a sequence of quarter-wave layers

Alternative term: Bragg mirrors

- mirrors

- dielectric mirrors

* Bragg mirrors

* quarter-wave mirrors

* dichroic mirrors

* chirped mirrors

* cold mirrors

* hot mirrors

- dielectric mirrors

Related: Bragg mirrorsdielectric mirrorschirped mirrorsdispersive mirrors

Page views in 12 months: 814

DOI: 10.61835/let Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

📦 For purchasing mirrors, use the RP Photonics Buyer's Guide — an expert-curated directory for finding all relevant suppliers, which also offers advanced purchasing assistance.

What is a Quarter-wave Mirror?

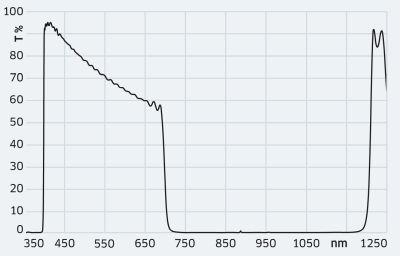

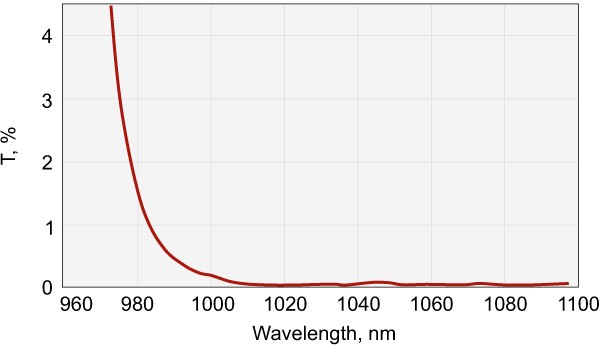

A quarter-wave mirror, also called a Bragg mirror, is usually a dielectric mirror (or semiconductor mirror) structure which consists of an alternating sequence of layers of two different optical materials, with each optical layer thickness corresponding to one-quarter of the wavelength for which the mirror is designed. Here, the wavelength is taken to be the wavelength within the material, not the vacuum wavelength. For a given wavelength and number of layer pairs, a quarter-wave mirror is the structure which can result in the highest reflectance.

Quarter-wave stacks are also very basic building blocks of more complicated dielectric mirror structures.

Frequently Asked Questions

This FAQ section was generated with AI based on the article content and has been reviewed by the article’s author (RP).

What is a quarter-wave mirror?

A quarter-wave mirror, also called a Bragg mirror, is a structure of alternating layers of two different optical materials, where each layer has an optical thickness of a quarter of the design wavelength.

Why is the quarter-wave design so common for mirrors?

For a given design wavelength and a certain number of layer pairs, the quarter-wave design is the structure which achieves the highest possible reflectance.

What are quarter-wave stacks used for?

Besides being used for simple high-reflectivity mirrors, quarter-wave stacks are fundamental building blocks for more complex structures like chirped mirrors.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 204 suppliers for mirrors. Among them:

⚙ hardware

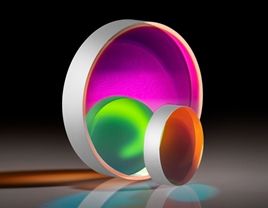

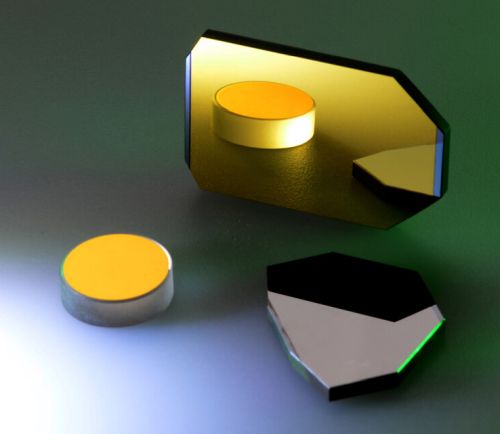

Edmund Optics offers a range of laser mirrors for use from the extreme ultraviolet (EUV) to the far IR. Laser mirrors designed for dye, diode, Nd:YAG, Nd:YLF, Yb:YAG, Ti:sapphire, fiber, and many more laser sources are available as flat mirrors, right angle mirrors, concave mirrors, and other specialty shapes. Ultrafast laser line mirrors designed to provide high reflection with minimal group delay dispersion (GDD) for femtosecond pulsed lasers including Er:glass, Ti:sapphire, and Yb:doped laser sources are also available.

⚙ hardware

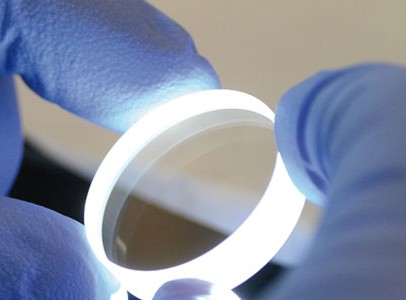

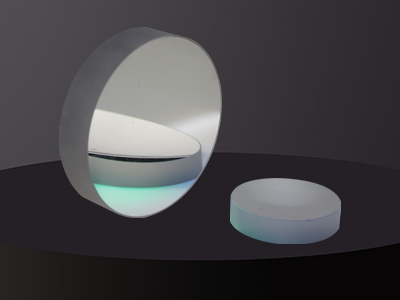

We offer custom optical mirrors on glass, fused silica, plastic or metal substrates. Round, parabolic, conic and free-form shapes. High quality high reflective coatings: silver, aluminium, gold or dielectric multi-layer designs.

⚙ hardware

IRD Glass manufactures first surface and second surface flat mirrors and laser mirrors that are used for interferometry, beam steering or folding, and many optical components within imaging systems. Our optical mirrors are completely customizable to meet our clients’ needs. From a basic protected aluminum through high laser damage threshold mirrors, IRD will certify the performance and specifications with whatever data you require.

⚙ hardware

Perkins Precision Developments (PPD) manufactures high energy laser mirrors and precision optics for both prototype and volume OEM requirements. We also offer custom Ion Beam Sputtered (IBS) thin film coatings for visible to near-infrared wavelengths on customer supplied substrates. PPD utilizes IBS coating technology because it is ideal for complex spectral designs, high power lasers and applications where it is critical to minimize losses from absorption and scatter.

Typical mirror coatings include dielectric low-loss high reflectors (HR), multi-wavelength high reflectors, dichroic mirrors, trichroic mirrors, partial beam splitter mirrors, non-polarizing and dispersion controlled mirrors.

⚙ hardware

Knight Optical offer stock mirrors including concave, elliptical, concave lamp reflectors and plane mirrors. Our mirror coatings include UV enhanced aluminium (180–650 nm), enhanced aluminium (450–650 nm), visible dielectric (450–700 nm), NIR dielectric (700–1064 nm), ion-plated silver (450–2000 nm), and protected gold (750 nm-far IR).

If your requirements are not met by our stock components, we can provide custom mirrors manufactured to your specifications.

⚙ hardware

UltraFast Innovations (UFI®) provides a range of mirrors mostly for ultrafast lasers. We particularly emphasize mirrors with broad bandwidth and well controlled chromatic dispersion.

⚙ hardware

Avantier specializes in producing custom optical precision mirrors for various applications, including but not limited to life sciences, astronomy, metrology, and solar engineering. These industries rely on our precision mirrors and other optical components to meet their specific needs.

⚙ hardware

Ecoptik can provide the round, square and customized shape mirrors with a protected Al coating and UV Enhanced Al coating in various sizes.

⚙ hardware

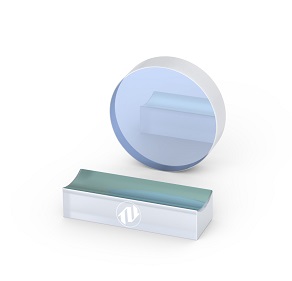

OPTOMAN manufactures a range of application-optimized laser mirrors, including extreme low-loss mirrors, dispersive mirrors, low GDD ultrafast mirrors and laser line mirrors. We focus on a single manufacturing technology — ion beam sputtering (IBS). OPTOMAN's IBS-coated mirrors feature high LIDT, spectral accuracy and environmental stability.

Standard in-stock IBS coated mirrors can be found in OPTOSHOP.

⚙ hardware

Artifex Engineering offers custom mirrors tailored to your requirements. Our mirrors can be manufactured in almost any shape: round, rectangular, elliptical, or any other shape including cut-outs and drill holes. Holes may also be drilled at an angle to the surface normal. We offer dielectric coatings and metal coatings (aluminium, silver or gold) with protective overcoat. Dielectric coatings are particularly developed for the respective application and enable precise wavelength ranges, so that individual wavelengths or selected ranges can be specified. Visit our product page for more information. We look forward to your inquiry.

⚙ hardware

LASEROPTIK can produce a wide range of laser mirrors with high reflectivity (HR) or partial reflectivity at given wavelength. We can also make specialty mirrors, e.g. with extremely broad reflection bands.

We use different coating technologies depending on your detailed requirements.

⚙ hardware

At Shanghai Optics we manufacture custom optical precision mirrors for a wide range of applications. Life sciences, astronomy, metrology, and solar engineering are only a few of the industries which depend on our precision mirrors and other optical components.

⚙ hardware

EKSMA Optics has a wide selection of dielectric and metal-coated mirrors on stock. Precision custom mirrors can be manufactured upon request.

⚙ hardware

MegaWatt Lasers has a large inventory of HR and OC mirrors for 1064 nm, 2.1 μm and 2.94 μm wavelengths. We also can assist in specification of optics for these wavelengths.

⚙ hardware🧩 accessories and parts🧴 consumables🔧 maintenance, repair📏 metrology, calibration, testing💡 consulting🧰 development

Discover the pinnacle of technologies with Shalom EO’s optical mirrors, where our diverse catalogs of mirror types like broadband dieletric mirrors, laser line dieletric mirrors, laser output couplers, metallic mirrors, femtoline low-GDD mirrors, high power laser mirrors, chirped mirrors and pairs, ultrafast-enhanced silver mirrors, super polished mirrors and mirror blanks cater to all sorts of demands. In addition, we also provide CO2 laser mirrors.

Shalom EO utilizes the cutting-edge ion-assisted electron beam evaporation coating technologies to realize pre-defined coating designs, where this coating technique contributes to denser film deposition and hence a higher laser induced damage threshold. The IAD e-beam coating technique, in combination with our precision-processed mirror substrates (which can be made from Corning glass, Schott glass), guarantees the good quality of our mirrors.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

photonic devices

photonic devices