Metals and Alloys - Young's Modulus of Elasticity (original) (raw)

Elastic properties and Young's modulus for metals and alloys like cast iron, carbon steel and more.

It is convenient to express the elasticity of a material with the ratio stress to strain, a parameter also termed as the tensile elastic modulus or Young's modulus of the material - usually with the symbol - E.

- Young's modulus can be used to predict the elongation or compression of an object.

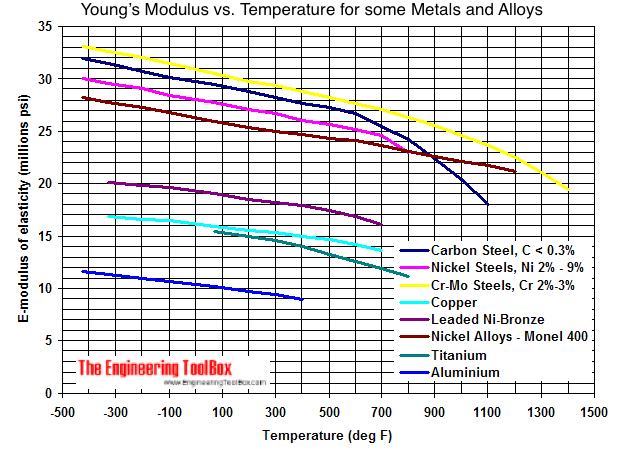

Modulus of Elasticity for some common metals at various temperatures according ASME B31.1-1995:

- 1 psi (lb/in2) = 1 psi (lb/in2) = 144 psf (lbf/ft2) = 6,894.8 Pa (N/m2) = 6.895×10-3 N/mm2

- T (oC) = 5/9 (T (oF) - 32)

For full table with Higher Temperatures - rotate the screen!

Metals and Alloys - Young's Modulus of Elasticity

| Metal | Young's Modulus of Elasticity - E - (106 psi) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (oC) | |||||||||||||||

| -200 | -129 | -73 | 21 | 93 | 149 | 204 | 260 | 316 | 371 | 427 | 482 | 538 | 593 | 649 | |

| Temperature (oF) | |||||||||||||||

| -325 | -200 | -100 | 70 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | |

| Cast iron | |||||||||||||||

| Gray cast iron | 13.4 | 13.2 | 12.9 | 12.6 | 12.2 | 11.7 | 11.0 | 10.2 | |||||||

| Steel | |||||||||||||||

| Carbon steel C <= 0.3% | 31.4 | 30.8 | 30.2 | 29.5 | 28.8 | 28.3 | 27.7 | 27.3 | 26.7 | 25.5 | 24.2 | 22.4 | 20.4 | 18.0 | |

| Carbon steel C => 0.3% | 31.2 | 30.6 | 30.0 | 29.3 | 28.6 | 28.1 | 27.5 | 27.1 | 26.5 | 25.3 | 24.0 | 22.2 | 20.2 | 17.9 | 15.4 |

| Carbon-molybdenum steels | 31.1 | 30.5 | 29.9 | 29.2 | 28.5 | 28.0 | 27.4 | 27.0 | 26.4 | 25.3 | 23.9 | 22.2 | 20.1 | 17.8 | 15.3 |

| Nickel steels Ni 2% - 9% | 29.6 | 29.1 | 28.5 | 27.8 | 27.1 | 26.7 | 26.1 | 25.7 | 25.2 | 24.6 | 23.0 | ||||

| Cr-Mo steels Cr 1/2% - 2% | 31.6 | 31.0 | 30.4 | 29.7 | 29.0 | 28.5 | 27.9 | 27.5 | 26.9 | 26.3 | 25.5 | 24.8 | 23.9 | 23.0 | 21.8 |

| Cr-Mo steels Cr 2 1/4% - 3% | 32.6 | 32.0 | 31.4 | 30.6 | 29.8 | 29.4 | 28.8 | 28.3 | 27.7 | 27.1 | 26.3 | 25.6 | 24.6 | 23.7 | 22.5 |

| Cr-Mo steels Cr 5% - 9% | 32.9 | 32.3 | 31.7 | 30.9 | 30.1 | 29.7 | 29.0 | 28.6 | 28.0 | 27.3 | 26.1 | 24.7 | 22.7 | 20.4 | 18.2 |

| Chromium steels Cr 12%, 17%, 27% | 31.2 | 30.7 | 30.1 | 29.2 | 28.5 | 27.9 | 27.3 | 26.7 | 26.1 | 25.6 | 24.7 | 23.2 | 21.5 | 19.1 | 16.6 |

| Austenitic steels (TP304, 310, 316, 321, 347) | 30.3 | 29.7 | 29.1 | 28.3 | 27.6 | 27.0 | 26.5 | 25.8 | 25.3 | 24.8 | 24.1 | 23.5 | 22.8 | 22.1 | 21.2 |

| Copper and copper alloys | |||||||||||||||

| Comp. and leaded-Sn bronze (C83600, C92200) | 14.8 | 14.6 | 14.4 | 14.0 | 13.7 | 13.4 | 13.2 | 12.9 | 12.5 | 12.0 | |||||

| Naval brass Si & Al bronze (C46400, C65500, C95200, C95400) | 15.9 | 15.6 | 15.4 | 15.0 | 14.6 | 14.4 | 14.1 | 13.8 | 13.4 | 12.8 | |||||

| Copper (C11000) | 16.9 | 16.6 | 16.5 | 16.0 | 15.6 | 15.4 | 15.0 | 14.7 | 14.2 | 13.7 | |||||

| Copper red brass Al-bronze (C10200, C12000, C12200, C12500, C14200, C23000, C61400) | 18.0 | 17.7 | 17.5 | 17.0 | 16.6 | 16.3 | 16.0 | 15.6 | 15.1 | 14.5 | |||||

| Nickel and Nickel Alloys | |||||||||||||||

| Monel 400 (N04400) | 27.8 | 27.3 | 26.8 | 26.0 | 25.4 | 25.0 | 24.7 | 24.3 | 24.1 | 23.7 | 23.1 | 22.6 | 22.1 | 21.7 | 21.2 |

| Titanium | |||||||||||||||

| Unalloyed titanium grades 1, 2, 3 and 7 | 15.5 | 15.0 | 14.6 | 14.0 | 13.3 | 12.6 | 11.9 | 11.2 | |||||||

| Aluminum and aluminum alloys | |||||||||||||||

| Grades 443, 1060, 1100, 3003, 3004, 6063 | 11.1 | 10.8 | 10.5 | 10.0 | 9.6 | 9.2 | 8.7 |

- 1 psi (lb/in2) = 6,894.8 N/m2 (Pa)

- T (oC) = 5/9 (T (oF) - 32)

Note! You can use the pressure unit converter to switch between units of Modulus of Elasticity.

My Short List

Related Topics

Properties of gases, fluids and solids. Densities, specific heats, viscosities and more.

Related Documents

Hooke's Law

Hooke's law - force, elongation and spring constant.

Modulus of Rigidity

Shear Modulus (Modulus of Rigidity) is the elasticity coefficient for shearing or torsion force.

Stiffness

Stiffness is resistance to deflection.

Our Mission

The Engineering ToolBox provides a wide range of free tools, calculators, and information resources aimed at engineers and designers. It offers detailed technical data and calculations for various fields such as fluid mechanics, material properties, HVAC systems, electrical engineering, and more.

The site includes resources for common engineering tasks, such as calculating physical properties (e.g., density, viscosity, thermal conductivity), converting units, and designing systems like heating and water distribution.

With sections on everything from acoustics to hydraulics, it serves as a comprehensive tool for both students and professionals in technical and engineering disciplines.

About the Engineering ToolBox!

Privacy Policy

We don't collect information from our users. More about our privacy policy here.

We use a third-party to provide monetization technology for our site. You can review their privacy and cookie policy here.

You can change your privacy settings by clicking the following button: .

Citation

This page can be cited as

- The Engineering ToolBox (2004). Metals and Alloys - Young's Modulus of Elasticity. [online] Available at: https://www.engineeringtoolbox.com/young-modulus-d\_773.html [Accessed Day Month Year].

Modify the access date according your visit.