Young’s Modulus of Elasticity – Values for Common Materials (original) (raw)

Tensile Modulus - or Young's Modulus alt. Modulus of Elasticity - is a measure of stiffness of an elastic material. It is used to describe the elastic properties of objects like wires, rods or columns when they are stretched or compressed.

Tensile Modulus is defined as the

"ratio of stress (force per unit area) along an axis to strain (ratio of deformation over initial length) along that axis"

It can be used to predict the elongation or compression of an object as long as the stress is less than the yield strength of the material. More about the definitions below the table.

Young's Modulus, Tensile Strength and Yield Strength Values common Materials

| Material | Tensile Modulus(Young's Modulus, Modulus of Elasticity) - E - (GPa) | Ultimate Tensile Strength - _σu - (MPa) | Yield Strength - _σy - (MPa) |

|---|---|---|---|

| ABS plastics | 1.4 - 3.1 | 40 | |

| A53 Seamless and Welded Standard Steel Pipe - Grade A | 331 | 207 | |

| A53 Seamless and Welded Standard Steel Pipe - Grade B | 414 | 241 | |

| A106 Seamless Carbon Steel Pipe - Grade A | 330 | 205 | |

| A106 Seamless Carbon Steel Pipe - Grade B | 415 | 240 | |

| A106 Seamless Carbon Steel Pipe - Grade C | 485 | 275 | |

| A252 Piling Steel Pipe - Grade 1 | 345 | 207 | |

| A252 Piling Steel Pipe - Grade 2 | 414 | 241 | |

| A252 Piling Steel Pipe - Grade 3 | 455 | 310 | |

| A501 Hot Formed Carbon Steel Structural Tubing - Grade A | 400 | 248 | |

| A501 Hot Formed Carbon Steel Structural Tubing - Grade B | 483 | 345 | |

| A523 Cable Circuit Steel Piping - Grade A | 331 | 207 | |

| A523 Cable Circuit Steel Piping - Grade B | 414 | 241 | |

| A618 Hot-Formed High-Strength Low-Alloy Structural Tubing - Grade Ia & Ib | 483 | 345 | |

| A618 Hot-Formed High-Strength Low-Alloy Structural Tubing - Grade II | 414 | 345 | |

| A618 Hot-Formed High-Strength Low-Alloy Structural Tubing - Grade III | 448 | 345 | |

| API 5L Line Pipe | 310 - 1145 | 175 - 1048 | |

| Acetals | 2.8 | 65 | |

| Acrylic | 3.2 | 70 | |

| Aluminum Bronze | 120 | ||

| Aluminum | 69 | 110 | 95 |

| Aluminum Alloys | 70 | ||

| Antimony | 78 | ||

| Aramid | 70 - 112 | ||

| Beryllium (Be) | 287 | ||

| Beryllium Copper | 124 | ||

| Bismuth | 32 | ||

| Bone, compact | 18 | 170 (compression) | |

| Bone, spongy | 76 | ||

| Boron | 3100 | ||

| Brass | 102 - 125 | 250 | |

| Brass, Naval | 100 | ||

| Bronze | 96 - 120 | ||

| CAB | 0.8 | ||

| Cadmium | 32 | ||

| Carbon Fiber Reinforced Plastic | 150 | ||

| Carbon nanotube, single-walled | 1000 | ||

| Cast Iron 4.5% C, ASTM A-48 | 170 | ||

| Cellulose, cotton, wood pulp and regenerated | 80 - 240 | ||

| Cellulose acetate, molded | 12 - 58 | ||

| Cellulose acetate, sheet | 30 - 52 | ||

| Cellulose nitrate, celluloid | 50 | ||

| Chlorinated polyether | 1.1 | 39 | |

| Chlorinated PVC (CPVC) | 2.9 | ||

| Chromium | 248 | ||

| Cobalt | 207 | ||

| Concrete | 17 | ||

| Concrete, High Strength (compression) | 30 | 40 (compression) | |

| Copper | 117 | 220 | 70 |

| Diamond (C) | 1220 | ||

| Douglas fir Wood | 13 | 50 (compression) | |

| Epoxy resins | 3-2 | 26 - 85 | |

| Fiberboard, Medium Density | 4 | ||

| Flax fiber | 58 | ||

| Glass | 50 - 90 | 50 (compression) | |

| Glass reinforced polyester matrix | 17 | ||

| Gold | 74 | ||

| Granite | 52 | ||

| Graphene | 1000 | ||

| Grey Cast Iron | 130 | ||

| Hemp fiber | 35 | ||

| Inconel | 214 | ||

| Iridium | 517 | ||

| Iron | 210 | ||

| Lead | 13.8 | ||

| Magnesium metal (Mg) | 45 | ||

| Manganese | 159 | ||

| Marble | 15 | ||

| MDF - Medium-density fiberboard | 4 | ||

| Mercury | |||

| Molybdenum (Mo) | 329 | ||

| Monel Metal | 179 | ||

| Nickel | 170 | ||

| Nickel Silver | 128 | ||

| Nickel Steel | 200 | ||

| Niobium (Columbium) | 103 | ||

| Nylon-6 | 2 - 4 | 45 - 90 | 45 |

| Nylon-66 | 60 - 80 | ||

| Oak Wood (along grain) | 11 | ||

| Osmium (Os) | 550 | ||

| Phenolic cast resins | 33 - 59 | ||

| Phenol-formaldehyde molding compounds | 45 - 52 | ||

| Phosphor Bronze | 116 | ||

| Pine Wood (along grain) | 9 | 40 | |

| Platinum | 147 | ||

| Plutonium | 97 | ||

| Polyacrylonitrile, fibers | 200 | ||

| Polybenzoxazole | 3.5 | ||

| Polycarbonates | 2.6 | 52 - 62 | |

| Polyethylene HDPE (high density) | 0.8 | 15 | |

| Polyethylene Terephthalate, PET | 2 - 2.7 | 55 | |

| Polyamide | 2.5 | 85 | |

| Polyisoprene, hard rubber | 39 | ||

| Polymethylmethacrylate (PMMA) | 2.4 - 3.4 | ||

| Polyimide aromatics | 3.1 | 68 | |

| Polypropylene, PP | 1.5 - 2 | 28 - 36 | |

| Polystyrene, PS | 3 - 3.5 | 30 - 100 | |

| Polyethylene, LDPE (low density) | 0.11 - 0.45 | ||

| Polytetrafluoroethylene (PTFE) | 0.4 | ||

| Polyurethane cast liquid | 10 - 20 | ||

| Polyurethane elastomer | 29 - 55 | ||

| Polyvinylchloride (PVC) | 2.4 - 4.1 | ||

| Potassium | |||

| Rhodium | 290 | ||

| Rubber, small strain | 0.01 - 0.1 | ||

| Sapphire | 435 | ||

| Selenium | 58 | ||

| Silicon | 130 - 185 | ||

| Silicon Carbide | 450 | 3440 | |

| Silver | 72 | ||

| Sodium | |||

| Steel, High Strength Alloy ASTM A-514 | 760 | 690 | |

| Steel, stainless AISI 302 | 180 | 860 | 502 |

| Steel, Structural ASTM-A36 | 200 | 400 | 250 |

| Tantalum | 186 | ||

| Thorium | 59 | ||

| Tin | 47 | ||

| Titanium | |||

| Titanium Alloy | 105 - 120 | 900 | 730 |

| Tooth enamel | 83 | ||

| Tungsten (W) | 400 - 410 | ||

| Tungsten Carbide (WC) | 450 - 650 | ||

| Uranium | 170 | ||

| Vanadium | 131 | ||

| Wrought Iron | 190 - 210 | ||

| Wood | |||

| Zinc | 83 |

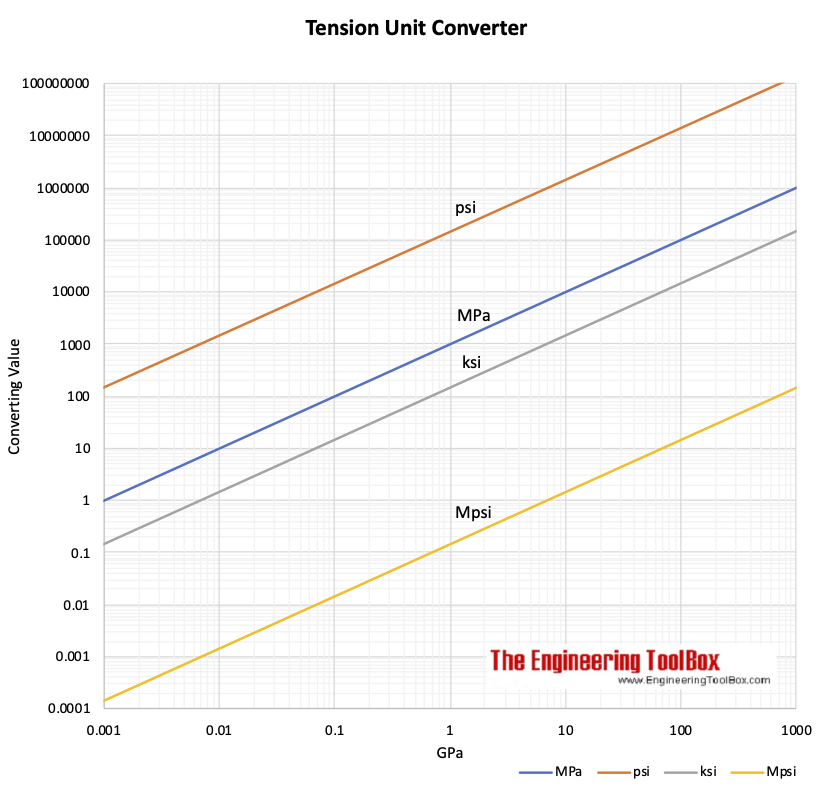

- 1 Pa (N/m2) = 1×10-6 N/mm2 = 1.4504×10-4 psi

- 1 MPa = 106 Pa (N/m2) = 0.145×103 psi (lbf/in2) = 0.145 ksi

- 1 GPa = 109 N/m2 = 105 N/cm2 = 103 N/mm2 = 0.145×106 psi (lbf/in2)

- 1 Mpsi = 106 psi = 103 ksi

- 1 psi (lb/in2) = 0.001 ksi = 144 psf (lbf/ft2) = 6,894.8 Pa (N/m2) = 6.895×10-3 N/mm2

Download and print Tension Unit Converter Chart

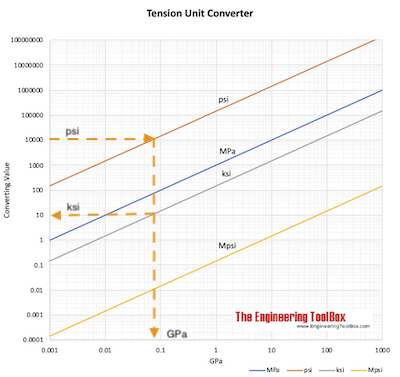

Example - Convert between Tension Units

10000 psi can be converted to 0.069 GPa and 10 ksi as indicated in the chart below:

Note! - this online pressure converter can also be used to convert between Tensile Modulus units.

Strain - _ε

Strain is the "deformation of a solid due to stress" - change in dimension divided by the original value of the dimension - and can be expressed as

_ε = dL / L (1)

where

_ε = strain (m/m, in/in)

dL = elongation or compression (offset) of object (m, in)

L = length of object (m, in)

Stress - σ

Stress is force per unit area and can be expressed as

σ = F / A (2)

where

σ = stress (N/m2, lb/in2, psi)

F = applied force (N, lb)

A = stress area of object (m2, in2)

- tensile stress - stress that tends to stretch or lengthen the material - acts normal to the stressed area

- compressible stress - stress that tends to compress or shorten the material - acts normal to the stressed area

- shearing stress - stress that tends to shear the material - acts in plane to the stressed area at right-angles to compressible or tensile stress

- Calculate stress in beams

Young's Modulus - Tensile Modulus, Modulus of Elasticity - E

Young's modulus can be expressed as

E = stress / strain

= σ / ε

= (F / A) / (dL / L) (3)

where

E = Young's Modulus of Elasticity (Pa, N/m2, lb/in2, psi)

- named after the 18th-century English physician and physicist Thomas Young

Elasticity

Elasticity is a property of an object or material indicating how it will restore it to its original shape after distortion.

A spring is an example of an elastic object - when stretched, it exerts a restoring force which tends to bring it back to its original length. This restoring force is in general proportional to the stretch described by Hooke's Law.

Hooke's Law

It takes about twice as much force to stretch a spring twice as far. That linear dependence of displacement upon the stretching force is called Hooke's law and can be expressed as

Fs = -k dL (4)

where

Fs = force in the spring (N)

k = spring constant (N/m)

dL = elongation of the spring (m)

Note that Hooke's Law can also be applied to materials undergoing three dimensional stress (triaxial loading).

Yield strength - σy

Yield strength is defined in engineering as the amount of stress (Yield point) that a material can undergo before moving from elastic deformation into plastic deformation.

- Yielding - a material deforms permanently

The Yield Point is in mild- or medium-carbon steel the stress at which a marked increase in deformation occurs without increase in load. In other steels and in nonferrous metals this phenomenon is not observed.

Ultimate Tensile Strength - σu

The Ultimate Tensile Strength - UTS - of a material is the limit stress at which the material actually breaks, with a sudden release of the stored elastic energy.

Related Documents

Ice - Properties

Properties like Youngs modulus, tensile strength, compressive strength and fracture of toughness for ice.

Modulus of Rigidity

Shear Modulus (Modulus of Rigidity) is the elasticity coefficient for shearing or torsion force.

Stiffness

Stiffness is resistance to deflection.

Stress

Stress is force applied on cross-sectional area.