hot mirrors (original) (raw)

Definition: mirrors which can reduce the heat load in an optical system by reflecting infrared radiation

Alternative term: heat control filters

Related: cold mirrorsdichroic mirrorsoptical filtersthermal radiation

Page views in 12 months: 674

DOI: 10.61835/qt9 Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

📦 For purchasing hot mirrors, use the RP Photonics Buyer's Guide — an expert-curated directory for finding all relevant suppliers, which also offers advanced purchasing assistance.

What are Hot Mirrors?

Particularly for image projectors which contain some kind of incandescent lamp (e.g. a halogen lamp) as a light source for the illumination, there can be a substantial heat load on the optical system. This is essentially because not only the desired visible light is generated, but also the more substantial power in the infrared. That infrared light may be absorbed in optical glasses, for example, heat them up, and cause various kinds of detrimental effects, such as mechanical stress and deformations which cause optical aberrations.

In order to eliminate or at least mitigate that problem, special mirrors (heat control filters) have been developed which can work in two different ways as optical filters for removing infrared light:

- Hot mirrors reflect the infrared radiation while transmitting most of the useful visible light. (They are sometimes called heat reflecting mirrors, although strictly speaking they reflect infrared radiation.) Such a mirror is simply added to the beam path before the optical components which need to be protected.

- Cold mirrors reflect the visible light, while transmitting or absorbing most of the infrared light. Such a mirror is used as a folding mirror in the optical beam path.

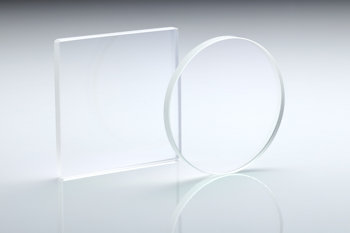

Figure 1: A hot mirror reflects thermal radiation while transmitting visible light.

In contrast to dichroic mirrors, which usually have specified optical properties only for two narrow wavelength regions, hot mirrors have such properties (although with less strict specifications) for much broader wavelength regions.

Hot mirrors are realized as dielectric mirrors. Such a mirror should ideally reflect all light in the near and mid infrared. However, such a large reflection bandwidth is hard to achieve, since the refractive index contrast of the usual coating materials is relatively small. Also, the common materials eventually get absorbing for long enough wavelengths. Therefore, part of the heat protection may be accomplished by absorbing infrared light; a high reflectivity is achieved mostly in the near infrared, e.g. only up to wavelengths around 1.3 μm or 1.5 μm.

The infrared absorption in the mirror substrate may lead to some thermal effects in the mirror, which may to some extent degrade the system performance. Such effects can be minimized by using a substrate glass with particularly good thermal resistance, including relatively small thermal expansion. For example, borosilicate glasses and fused silica are suitable for that purpose. Soda–lime glasses are sufficient only for lower powers.

As is common for dielectric mirrors, the reflection spectrum is optimized for a certain angle of incidence — for example, for normal incidence or for 45° — and the performance can be substantially worse for other incidence angles.

Frequently Asked Questions

What is a hot mirror?

A hot mirror is a specialized optical filter that reflects infrared radiation while transmitting most visible light. They are used to protect optical components from heat generated by light sources like incandescent lamps in devices such as image projectors.

How does a hot mirror differ from a cold mirror?

A hot mirror reflects infrared light and transmits visible light. In contrast, a cold mirror reflects visible light while transmitting or absorbing infrared radiation, and is typically used as a folding mirror in an optical system.

What kind of technology is used for hot mirrors?

Hot mirrors are realized as dielectric mirrors, which use a multi-layer coating of dielectric materials on a substrate. This coating is designed to create high reflectivity for a broad range of infrared wavelengths and high transmission for visible light.

Are there limitations to the performance of hot mirrors?

Yes, their reflection spectrum is optimized for a specific angle of incidence. Also, their reflection bandwidth is limited; they may absorb some longer-wavelength infrared light, which can heat the mirror and requires a substrate with good thermal resistance like fused silica.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 26 suppliers for hot mirrors. Among them:

⚙ hardware

Edmund Optics offers various specialty mirrors, including hot mirrors which reflect 90% of NIR and IR light. We also have extended hot mirrors with improved NIR reflectance and high performance versions with an optimized multi-layer dielectric coating.

⚙ hardware

Knight Optical can provide hot mirrors from stock in 25 mm to 50 mm diameters or 25 mm × 25 mm to 100 mm × 100 mm squares, however these can be cut to custom dimensions with a quick turnaround. Hot mirrors reflect IR whilst transmitting visible light. These mirrors are an alternative to our KG1 heat filters which absorbs the infrared light rather than reflecting it.

⚙ hardware

Hot and cold mirrors are both specialized dielectric mirrors which are used for heat control; to filter unwanted energy from a light source. A cold mirror will reflect 90% of the visible light spectrum while efficiently transmitting (and thus removing from the site of interest) infrared wavelengths. A hot mirror will reflect 90% of infrared and near infrared light, and transmit a large portion of visible light (up to 80%). Shanghai Optics can manufacture custom hot and cold mirrors for any angle of incidence desired, from 0 to 45°.

⚙ hardware

Dielectric mirrors, such as hot and cold mirrors, are specifically designed to regulate heat by filtering out undesired energy from a light source. Cold mirrors are capable of reflecting 90% of visible light spectrum and effectively transmitting infrared wavelengths, thereby removing them from the area of interest. On the other hand, hot mirrors can reflect 90% of infrared and near-infrared light while transmitting a significant portion of visible light (up to 80%). Avantier has the capability to produce tailor-made hot and cold mirrors for any angle of incidence, ranging from 0 to 45°.

⚙ hardware

Artifex Engineering offers custom hot mirrors tailored to your requirements for shape, coating and other specifications. Visit our product page for more information. We look forward to your inquiry.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.

photonic devices

photonic devices