Bolt Stretching and Tensile Stress (original) (raw)

Tensile stress and Hooke's Law.

Elongation

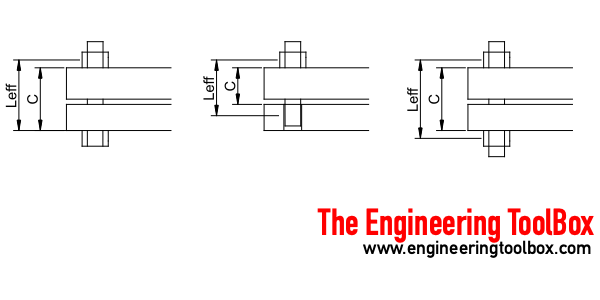

Bolt stretching according Hook's Law can be calculated as

dl = F L / E A (1)

where

dl = change in length of bolt (inches, m)

F = applied tensile load (lb, N)

Leff = effective length of bolt where tensile strength is applied (inches, m)

E = Young's Modulus of Elasticity (psi, N/m2)

A = tensile stress area of the bolt (square inches, m2)

Stress Area

The tensile stress area can be calculated as

A = (π / 4) (d - 0.9743 / n)2 (2)

where

d = nominal diameter of bolt (in)

n = 1 / p = number of threads per inch

p = pitch, length per thread (in)

Tensile Stress

Tensile stress can be calculated as

σ = F / A (3)

where

σ = tensile stress (psi, N/m2 (Pa))

Example - Bolt Stretching - Imperial Units

- stud diameter : 7/8 inches

- thread pitch : 9

- Young's Modulus steel : 30 106 psi

- designed bolt load : 10000 lb

- effective length : 5 inches

The tensile stress area can be calculated as

A = 0.7854 ((7/8 in) - 0.9743 / 9)2

= 0.46 (in2)

The elongation can be calculated as

dl = (10000 lb) (5 in) / ((30 106 psi) (0.46 in2))

= 0.0036 (inches)

The tensile stress can be calculated as

σ = (10000 lb) / (0.46 in2)

= 21740 psi

Related Topics

Bolts, nuts and threaded rods - torque, tension and loads.

Related Documents

The ASME B16 standards covers pipes and fittings in cast iron , cast bronze, wrought copper and steel.

Calculate required bolt torque.

Flange diameters, thickness, bolt circles, numbers and diameter of bolts for ASME/ANSI B16.15 - Cast Bronze Threaded Fittings - 300 lb Bronze - Flanges with plain faces.

The number, diameter and length of studs for cast iron flanges class 125 and 250.

Hooke's law - force, elongation and spring constant.

Dimensions of metric threads according ISO 724.

Elastic properties and Young's modulus for metals and alloys like cast iron, carbon steel and more.

ANSI/SO, DIN and JIS bolts.

Minimum ultimate tensile and proof loads for metric bolts with coarse or fine threads.

Metric steel bolts, screws and studs - proof and tensile strength.

Shear Modulus (Modulus of Rigidity) is the elasticity coefficient for shearing or torsion force.

Pressure numbers (PN) vs. flange class designations.

Gasket dimensions according ASME B16.5 Pipe Flanges and Flange Fittings.

Lubrication effect on bolt tension and torque.

ASTM steel bolts - proof and tensile strength.

SAE steel bolts - grades ranging grade 1 to 8.2 - proof and tensile strength.

Threaded bolts tensile stress area.

ANSI/ASME B1.1 Unified National Thread - UNC Coarse series and UNF Fine series.

Tensile strength and proof loads SAE bolts.

ANSI/ASME B18.2.1 Dimensions of Hex Bolts - Imperial units.

ANSI/ASME B18.2.3M Dimensions of Hex Bolts - Metric units.

Convert between US Inches and metric mm wrench and spanner sizes.

Young's Modulus (or Tensile Modulus alt. Modulus of Elasticity) and Ultimate Tensile Strength and Yield Strength for materials like steel, glass, wood and many more.

About the Engineering ToolBox!

Privacy Policy

We don't collect information from our users. More about

We use a third-party to provide monetization technologies for our site. You can review their privacy and cookie policy here.

You can change your privacy settings by clicking the following button: .

Citation

This page can be cited as

- The Engineering ToolBox (2008). Bolt Stretching and Tensile Stress. [online] Available at: https://www.engineeringtoolbox.com/bolt-stretching-d\_1164.html [Accessed Day Month Year].

Modify the access date according your visit.