Poisson's Ratio (original) (raw)

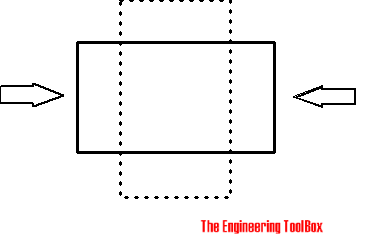

When a material is stretched in one direction it tends to get thinner in the other two directions.

When a sample of material is stretched in one direction it tends to get thinner in the lateral direction - and if a sample is compressed in one direction it tends to get thicker in the lateral direction.

Poisson's ratio is

- the ratio of the relative contraction strain (transverse, lateral or radial strain) normal to the applied load - to the relative extension strain (or axial strain) in the direction of the applied load

Poisson's Ratio can be expressed as

μ = - εt / εl (1)

where

μ = Poisson's ratio

εt = transverse strain (m/m, ft/ft)

εl = longitudinal or axial strain (m/m, ft/ft)

Strain is defined as "deformation of a solid due to stress".

Longitudinal (or axial) strain can be expressed as

εl = dl / L (2)

where

εl = longitudinal or axial strain (dimensionless - or m/m, ft/ft)

dl = change in length (m, ft)

L = initial length (m, ft)

Contraction (or transverse, lateral or radial) strain can be expressed as

εt = dr / r (3)

where

εt = transverse, lateral or radial strain (dimensionless - or m/m, ft/ft)

dr = change in radius (m, ft)

r = initial radius (m, ft)

Eq. 1, 2 and 3 can be combined to

μ = - ( dr / r ) / ( dl / L ) (4)

Example - Stretching Aluminum

An aluminum bar with length 10 m and radius 100 mm (100 10-3 m) is stretched 5 mm (5 10-3 m) . The radial contraction in lateral direction can be rearranged to

dr = - μ r dl / L (5)

With Poisson's ratio for aluminum 0.334 - the contraction can be calculated as

dr = - 0.334 ( 100 10-3 m ) ( 5 10-3 m) / (10 m)

= 1.7 10 -5 m

= 0.017 mm

Poisson's Ratios for Common Materials

For most common materials the Poisson's ratio is in the range 0 - 0.5 . Typical Poisson's Ratios for some common materials are indicated below.

Poisson's Ratios common Materials

| Material | Poisson's Ratio - μ - |

|---|---|

| Upper limit | 0.5 |

| Aluminum | 0.334 |

| Aluminum, 6061-T6 | 0.35 |

| Aluminum, 2024-T4 | 0.32 |

| Beryllium Copper | 0.285 |

| Brass, 70-30 | 0.331 |

| Brass, cast | 0.357 |

| Bronze | 0.34 |

| Clay | 0.41 |

| Concrete | 0.1 - 0.2 |

| Copper | 0.355 |

| Cork | 0 |

| Glass, Soda | 0.22 |

| Glass, Float | 0.2 - 0.27 |

| Granite | 0.2 - 0.3 |

| Ice | 0.33 |

| Inconel | 0.27 - 0.38 |

| Iron, Cast - gray | 0.211 |

| Iron, Cast | 0.22 - 0.30 |

| Iron, Ductile | 0.26 - 0.31 |

| Iron, Malleable | 0.271 |

| Lead | 0.431 |

| Limestone | 0.2 - 0.3 |

| Magnesium | 0.35 |

| Magnesium Alloy | 0.281 |

| Marble | 0.2 - 0.3 |

| Molybdenum | 0.307 |

| Monel metal | 0.315 |

| Nickel Silver | 0.322 |

| Nickel Steel | 0.291 |

| Polystyrene | 0.34 |

| Phosphor Bronze | 0.359 |

| Rubber | 0.48 - ~0.5 |

| Sand | 0.29 |

| Sandy loam | 0.31 |

| Sandy clay | 0.37 |

| Stainless Steel 18-8 | 0.305 |

| Steel, cast | 0.265 |

| Steel, Cold-rolled | 0.287 |

| Steel, high carbon | 0.295 |

| Steel, mild | 0.303 |

| Titanium (99.0 Ti) | 0.32 |

| Wrought iron | 0.278 |

| Z-nickel | 0.36 |

| Zinc | 0.331 |

Related Topics

The relationships between forces, acceleration, displacement, vectors, motion, momentum, energy of objects and more.

Engineering related topics like Beaufort Wind Scale, CE-marking, drawing standards and more.

Related Documents

Plastic deformation properties.

The machinability of some common metals.

The Bulk Modulus - resistance to uniform compression - for some common metals and alloys.

Elastic properties and Young's modulus for metals and alloys like cast iron, carbon steel and more.

Shear Modulus (Modulus of Rigidity) is the elasticity coefficient for shearing or torsion force.

Some metals and their Poisson's Ratios.

The relative values between quantities - ratios and proportions.

Stress is force per unit area - strain is the deformation of a solid due to stress.

Young's Modulus (or Tensile Modulus alt. Modulus of Elasticity) and Ultimate Tensile Strength and Yield Strength for materials like steel, glass, wood and many more.

About the Engineering ToolBox!

Privacy Policy

We don't collect information from our users. More about

We use a third-party to provide monetization technologies for our site. You can review their privacy and cookie policy here.

You can change your privacy settings by clicking the following button: .

Citation

This page can be cited as

- The Engineering ToolBox (2008). Poisson's Ratio. [online] Available at: https://www.engineeringtoolbox.com/poissons-ratio-d\_1224.html [Accessed Day Month Year].

Modify the access date according your visit.