direct diode lasers (original) (raw)

Acronym: DDL = direct diode laser

Definition: diode lasers which are directly used e.g. for material processing

Category:  laser devices and laser physics

laser devices and laser physics

- semiconductor lasers

- diode lasers

* high-brightness laser diodes

* diode bars

* diode stacks

* vertical cavity surface-emitting lasers

* external-cavity diode lasers

* fiber-coupled diode lasers

* mode-locked diode lasers

* laser diode modules

* direct diode lasers

* (more topics)

- diode lasers

Related: diode lasersdiode-pumped laserssolid-state lasersbrightness convertersbeam combininglaser applicationslaser cutting

Page views in 12 months: 580

DOI: 10.61835/jed Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

📦 For purchasing direct diode lasers, use the RP Photonics Buyer's Guide — an expert-curated directory for finding all relevant suppliers, which also offers advanced purchasing assistance.

Contents

What are Direct Diode Lasers?

Direct diode lasers are laser devices where the output of laser diodes is directly used for an application — frequently in laser material processing, e.g. in the form of laser cutting or laser welding. This is in contrast to using diode-pumped lasers, where the diode laser radiation is used for pumping another laser, typically a solid-state laser, the output of which is then sent to the application. That additional laser usually acts as a brightness converter: although some of the optical power is lost, the beam quality of its output is so much higher than that of the diode laser(s) that the brightness (more precisely: the radiance) is still higher. This allows for increased optical intensities on workpieces, for example.

The direct use of diode lasers is attractive for different reasons:

- Such laser sources are overall simpler and more compact, also potentially much cheaper than alternative solutions.

- Their wall-plug efficiency is substantially higher, as conversion losses are avoided. That can greatly reduce the electric energy consumption.

Figure 1: Laser cutting in stainless steel with a direct diode laser. Source: Fraunhofer ILT, Aachen, Germany.

Used Diode Lasers

Direct diode lasers are usually based on gallium arsenide technology, which allows for emission wavelengths of typically between 0.8 μm and 1 μm.

Many direct diode laser applications require substantial output powers. One uses not only single diode bars, which are suitable for powers of the order of 100 W, but also diode stacks, containing multiple diode bars and delivering powers of 1 kW or even several kilowatts. It is also possible to do spectral beam combining with several diode stacks operating at somewhat different wavelengths.

The improved radiance of high-power laser diodes has different origins. One factor is the continuous increase of radiance of diode bars and diode stacks through improvements of their design. For example, there are tapered laser diodes and tapered amplifiers with much increased beam quality. Another factor is improved methods and components for beam combination of the radiation of many laser diodes.

Advantages and Limitations

However, the beam quality of high-power laser diodes has for many years been clearly too low for direct application in laser material processing, e.g. laser welding. The rapid technical progress in this area has in recent years increased their beam quality and radiance to such high levels that many direct diode applications have become possible. Direct diode lasers are therefore now even used for metal cutting and welding, particularly for conduction welding of relatively thin metal sheets. Laser soldering and brazing, laser cladding and some laser surface treatments also belong to their applications.

Free Space or Fiber Coupling

In the same way as solid-state lasers, direct diode laser products can either emit a free-space laser beam or can be fiber-coupled. Beam delivery through an optical fiber is beneficial for many applications, and becomes feasible if the beam quality of the source is sufficiently high.

Frequently Asked Questions

What is a direct diode laser?

A direct diode laser is a device where the output of laser diodes is used directly for an application, such as material processing, rather than for pumping another laser.

What are the main advantages of direct diode lasers?

Their main advantages are a simpler and more compact design, lower cost, and substantially higher wall-plug efficiency compared to diode-pumped systems, as energy conversion losses are avoided.

What are typical applications of direct diode lasers?

They are frequently used for laser material processing, including metal cutting and welding, laser soldering and brazing, laser cladding, and various laser surface treatments.

How are high powers achieved with direct diode lasers?

High output powers are obtained by using diode stacks containing multiple diode bars. The power can be scaled further by combining the beams from several stacks, for example with spectral beam combining.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 21 suppliers for direct diode lasers. Among them:

⚙ hardware

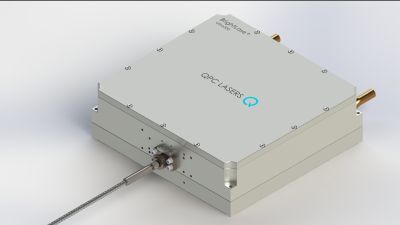

QPC Lasers full vertical integration from epitaxy through packaging allows us to offer standard and custom diode solutions in packages ranging from open heat-sink mounts to complete OEM light engines that provide performance without compromise.

⚙ hardware

The Lumics LuOcean diode lasers are ideal for OEM integrators aiming to develop state-of-the-art end-user laser systems, featuring single emitters with a very long service life and up to four different wavelengths. Users can choose from a wide range of wavelengths, including 670 nm, 760 nm, 785 nm, 808 nm, 890 nm, 915 nm, 940 nm, 975 nm, 1064 nm, 1470 nm, and 1940 nm with custom wavelengths and specifications available upon request. The modules can be configured to match the customers power requirements. Optional enhancements such as temperature, fiber and power monitor sensors and pilot beams further extend the module's capabilities.

⚙ hardware

Hamamatsu Photonics DDL is a laser heating light source that efficiency transmits and focuses laser from the LD stack module and directly irradiates the materials. Since DDL dose not use optical fiber, it is an energy-saving light source with little transmission loss due to complicated optical systems. DDL can be used for a variety of applications including for heat processing such as welding, hardening and cladding as well as pumping of solid-state lasers.

⚙ hardware

SHIPS TODAY: AeroDIODE offers fiber-coupled laser diodes with very high brightness (meaning high power and high precision when focusing) dedicated to micromachining applications between 808 nm and 1550 nm as stock items or associated with a high power laser diode driver with air cooling. Most turn-key diode & driver solutions are optimized for single-shot to CW performances. Many multimode versions are available with CW emission up to 450 W in a 200-µm core multimode fiber or up to 250 W in a 135-µm core fiber or 160 W in a 105-µm core fiber. The highest brightness/power models are based on special laser diodes for emission at 808 nm, 915 nm, 940 nm, 980 nm or 1064 nm.

See also our tutorial on fiber-coupled laser diodes.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.