fiber-optic sensors (original) (raw)

Definition: optical sensors based on fiber devices

Alternative term: fiber sensors

Categories:  fiber optics and waveguides,

fiber optics and waveguides,  photonic devices

photonic devices

- optical sensors

- optical strain sensors

- optical temperature sensors

- fiber-optic sensors

Related: optical sensorsfibersfiber Bragg gratingsoptical strain sensorsoptical temperature sensorssingle-frequency laserslaser applications

Page views in 12 months: 1211

DOI: 10.61835/sxe Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

📦 For purchasing fiber-optic sensors, use the RP Photonics Buyer's Guide — an expert-curated directory for finding all relevant suppliers, which also offers advanced purchasing assistance.

Contents

What is a Fiber-optic Sensor?

Fiber-optic sensors (also called optical fiber sensors) are fiber-based optical sensors for some quantity, typically temperature or mechanical strain, but sometimes also displacements, vibrations, pressure, acceleration, rotations (measured with optical gyroscopes based on the Sagnac effect), or concentrations of chemical species. The general principle of such devices is that light from a laser (often a single-frequency fiber laser) or from a superluminescent source is sent through an optical fiber, experiences subtle changes in its parameters either in the fiber or in one or several fiber Bragg gratings, and then reaches a detector arrangement which measures these changes.

One distinguishes intrinsic and extrinsic sensors. Intrinsic sensors are those where a fiber itself (possibly in a modified form, e.g. containing a Bragg grating) acts as the sensor. Extrinsic sensors use fibers only for transporting light to and from the actual sensor.

Many fiber-optic sensors are based on single fibers, but others are made with fiber bundles. For example, there are extrinsic sensors where some illumination light is sent to a sample through some of the fibers of a bundle, and reflected light or induced fluorescence light is sent back through other fibers.

Compared with other types of sensors, fiber-optic sensors exhibit a number of advantages:

- They consist of electrically insulating materials (no electric cables are required), which makes possible their use e.g. in high-voltage environments.

- They can be safely used in explosive environments because there is no risk of electrical sparks, even in the case of defects.

- They are immune to electromagnetic interference (EMI), even to nearby lightning strikes, and do not themselves electrically disturb other devices.

- Their materials (e.g. fused silica) can be chemically passive, i.e., do not contaminate their surroundings and are not subject to corrosion.

- They have a very wide operating temperature range (much wider than is possible for many electronic devices).

- They have multiplexing capabilities: multiple sensors in a single fiber line can be interrogated with a single optical source (see below).

Bragg Grating Sensors

Many fiber-optic sensors are based on fiber Bragg gratings. The basic operation principle is often that the Bragg wavelength (i.e., the wavelength of maximum reflectance) of a fiber Bragg grating depends not only on the Bragg grating period but also on temperature and mechanical strain.

For optical strain sensors based on silica fibers, the fractional response of the Bragg wavelength to strain is roughly 20% smaller than the strain itself, since the direct effect of strain is to some extent reduced by a decrease in refractive index. The temperature effect is close to that expected from thermal expansion alone. The effects of strain and temperature can be distinguished with various techniques (e.g. by using reference gratings which are subject to the same temperature but not to the strain, or by combining different types of fiber gratings), so that strain and temperature are obtained at the same time.

For pure strain sensing, the resolution can be the range of a few με (i.e., relative length changes of a few times 10−6), and the accuracy may be of the same order. For dynamic measurements (e.g. of acoustic phenomena), sensitivities better than 1 nε in a 1-Hz bandwidth are achievable.

There are also Bragg grating laser sensors, where small fiber lasers are realized, consisting of two gratings and a rare-earth doped fiber in between. Alternatively, there can be one FBG and a broadband reflector on the other side. When supplied with pump light, such a device produces an output with a wavelength close to the Bragg wavelength. That emission wavelength can then be measured, and notably it can hardly be influenced even during propagation in a rather long fiber — in contrast to amplitude-coded signals, which may be affected by attenuation.

Quasi-distributed Sensing

A single fiber may contain many grating sensors (see above) in series to monitor the temperature and strain distribution along the whole fiber. This is called quasi-distributed sensing. There are different techniques to address the single gratings (and thus certain locations along the fiber):

- In one technique, called wavelength division multiplexing (WDM) or optical frequency-domain reflectometry (OFDR), the gratings have slightly different Bragg wavelengths. A wavelength-tunable laser in the interrogator unit can be tuned to the wavelength belonging to a particular grating, and the wavelength of maximum reflectance indicates the influences of strain or temperature, for example. Alternatively, a broadband light source (e.g. a superluminescent source) may be used together with a wavelength-swept photodetector (e.g. based on a fiber Fabry–Pérot) or a CCD-based spectrometer. In any case, the maximum number of gratings is typically between 10 and 50, limited by the tuning range or bandwidth of the light source and the required wavelength interval per fiber grating.

- Another technique, called time division multiplexing (TDM), uses identical weakly reflecting gratings, interrogated with short light pulses. The reflections from different gratings are then distinguished via their arrival times. Time division multiplexing is often combined with wavelength division multiplexing to multiply the number of different channels to hundreds or even thousands.

- An optical switch allows one to select between different fiber lines, further multiplying the possible number of sensors.

Distributed Sensing

Other fiber-optic sensors do not use fiber Bragg gratings as sensors, but rather the fiber itself. The principle of sensing can then be based on Rayleigh scattering, Raman scattering or Brillouin scattering. For example, optical time domain reflectometry is a method where weak reflections can be localized using a pulsed probe signal. It is also possible, e.g., to exploit the temperature or strain dependence of the Brillouin frequency shift.

In some cases, the measured quantity is a kind of average over the full fiber length. This is the case for certain temperature sensors but also for Sagnac interferometers used as gyroscopes. In other cases, position-dependent quantities (e.g. temperatures or strains) are measured. This is called distributed sensing. A single fiber may then e.g. replace a large number of electronic temperature sensors.

See the articles on optical temperature sensors and optical strain sensors for more details.

Other Approaches

Apart from the approaches described above, there are many alternative techniques. Some examples are:

- Fiber Bragg gratings may be used in interferometric fiber sensors, where they merely serve as reflectors, and the measured phase shift results from fiber spans between them. Pairs of fiber Bragg gratings are used as fiber Fabry–Pérot interferometers, which can react particularly sensitively to external influences. (A Fabry–Pérot interferometer can also be made with other means, e.g. with a variable air gap in the fiber.) Such techniques can also be implemented with multiple fiber segments; the method (usable for dynamic sensing) is then called fiber segment interferometry [12]. Using a sinusoidal optical frequency modulation, which can be easily achieved with current modulation of a single-frequency laser diode, in combination with suitable signal processing (e.g. using a field programmable gate array (FPGA)), one can separately measure the average strain in any particular fiber segment with high temporal resolution [11].

- There are Bragg grating laser sensors, where a sensor grating forms the end mirror of a fiber laser resonator, containing e.g. some erbium-doped fiber, which receives 980-nm pump light via the fiber line. The Bragg wavelength, which depends on e.g. temperature or strain, determines the lasing wavelength. This approach, which has many further variations, promises very high resolution due to the small linewidth of such a fiber laser, and very high sensitivity.

- Long-period fiber gratings are particularly interesting for multi-parameter sensing (e.g. of temperature and strain), and alternatively for strain sensing with very low sensitivity to temperature changes.

Applications

Even after a substantial number of years of development, fiber-optic sensors have still not become very widespread, since it is difficult to replace already well-established technologies, even if they exhibit certain limitations. For some application areas, however, fiber-optic sensors are increasingly recognized as a technology with very interesting possibilities. This holds particularly for harsh environments, such as sensing in high-voltage and high-power machinery, or in microwave ovens. Bragg grating sensors can also be used to monitor the conditions e.g. within the wings of airplanes, in wind turbines, bridges, large dams, oil wells and pipelines. Buildings with integrated fiber-optic sensors are sometimes called “smart structures”; they allow one to monitor the inside conditions and to gain important information on the strain to which different parts of the structure are subject, on aging phenomena, vibrations, etc. Smart structures are a main driver for the further development of fiber-optic sensors.

Frequently Asked Questions

What is a fiber-optic sensor?

A fiber-optic sensor is a device that uses an optical fiber to measure quantities like temperature, strain, pressure, or chemical concentrations. It works by sending light through the fiber and detecting changes in the light's properties caused by the external influence.

What are the main advantages of fiber-optic sensors?

They are immune to electromagnetic interference, inherently safe for explosive environments, chemically passive, and operate over a wide temperature range. They also allow for multiplexing, where many sensors on a single fiber line can be monitored.

What is the difference between intrinsic and extrinsic fiber sensors?

In an intrinsic sensor, the optical fiber itself acts as the sensing element. In an extrinsic sensor, the fiber is only used to transmit light to and from a separate, external sensing device.

How do fiber Bragg grating (FBG) sensors work?

A fiber Bragg grating (FBG) reflects a specific wavelength of light. This 'Bragg wavelength' shifts in response to changes in temperature or mechanical strain, allowing these quantities to be precisely measured by monitoring the reflected light's wavelength.

What is quasi-distributed sensing?

Quasi-distributed sensing involves placing multiple discrete sensors, such as fiber Bragg gratings, at various points along a single optical fiber. This allows for measurements at many specific locations using one fiber and a single interrogation unit.

What is distributed sensing?

Distributed sensing uses the entire length of an optical fiber as a continuous sensor. By analyzing backscattered light (e.g., from Rayleigh scattering or Brillouin scattering), it can measure quantities like temperature or strain at any point along the fiber.

What are common applications of fiber-optic sensors?

They are used in harsh environments and for structural health monitoring of airplanes, wind turbines, bridges, and buildings ('smart structures'). They are also employed in the energy sector for monitoring oil wells and pipelines.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 57 suppliers for fiber-optic sensors. Among them:

⚙ hardware

Fiber Bragg grating sensors are commonly used in structural deformation and temperature monitoring. Short-period fiber grating sensors are commonly used, and their reflection wavelengths are called Bragg wavelengths. Such sensors are called FBG sensors.

⚙ hardware

HBK FiberSensing newLight sensor technology enables large strain measurement ranges at increased long-term stability. It is the ideal choice for structural health monitoring due to its fast and easy installation and its resistance to environmental conditions such as humidity, rust, and salt even over extremely long distances.

The compatibility with standard telecom cables makes this line very cost efficient — especially for medium-to-high channel applications. The newLight range is based on the Fiber Bragg Grating technology and offers optical sensors for measurements of strain, temperature, accelerometer, and tilt.

In addition to fiber optical sensors that measure strain, temperature, acceleration, tilt or displacement, HBK also offers optical interrogators, software, as well as service and support for every application.

⚙ hardware

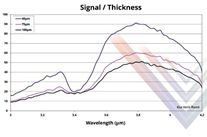

LVF develops fiber-optic sensors based on its fluoride fiber technology. Discover our optical thickness sensor based on absorption spectroscopy.

⚙ hardware🧰 development

Diamond SA provides integrated solutions for distributed and punctual fiber optic sensors. Its ultra-low loss connectors enhance the sensitivity of the sensors and are suitable for the most severe operating environments. Diamond Active Core Alignment (ACA) technology maximizes the signal to noise ratio of the detected parameters, reducing drastically the interconnects power losses.

High stability and reliability are key features, mostly in harsh environments, where atmospheric agents or vibrations can affect the precision of the measurement. In space-avionics sensors applications, Diamond's “Mini AVIM®” is the only connector certified space-grade worldwide. Diamond optical sensors assemblies with Fiber Bragg Gratings (FBG), special fibers, mirror terminations or miniaturized components, cover a wide range of applications and are customized on your needs.

Bibliography

| [1] | D. Culverhouse et al., “Potential of stimulated Brillouin scattering as sensing mechanism for distributed temperature sensor”, Electron. Lett. 25, 913 (1989); doi:10.1049/el:19890612 |

|---|---|

| [2] | A. D. Kersey, “A review on recent developments in fiber optic sensor technology”, Opt. Fiber Technol. 2, 291 (1996); doi:10.1006/ofte.1996.0036 |

| [3] | A. D. Kersey et al., “Fiber grating sensors”, IEEE J. Lightwave Technol. 15 (8), 1442 (1997); doi:10.1109/50.618377 |

| [4] | B. Lee, “Review of the present status of optical fiber sensors”, Opt. Fiber Technol. 9 (2), 57 (2003); doi:10.1016/S1068-5200(02)00527-8 |

| [5] | L. Zou et al., “Coherent probe-pump-based Brillouin sensor for centimeter-crack detection”, Opt. Lett. 30 (4), 370 (2005); doi:10.1364/OL.30.000370 |

| [6] | F. M. Cox et al., “Opening up optical fibres”, Opt. Express 15 (19), 11843 (2007); doi:10.1364/OE.15.011843 |

| [7] | O. Franzão et al., “Optical sensing with photonic crystal fibers”, Laser & Photon. Rev. 2 (6), 449 (2008); doi:10.1002/lpor.200810034 |

| [8] | J. Albert et al., “Tilted Bragg grating sensors”, Laser & Photon. Rev. 7 (1), 83 (2013); doi:10.1002/lpor.201100039 |

| [9] | P. Roriz et al., “Review of fiber-optic pressure sensors for biomedical and biomechanical applications”, J. Biomed. Opt. 18 (5), 050903 (2013); doi:10.1117/1.JBO.18.5.050903 |

| [10] | L. Mescia and F. Prudenzano, “Advances on optical fiber sensors”, Fibers 2 (1), 1 (2014); doi:10.3390/fib2010001 |

| [11] | T. Kissinger et al., “Range-resolved interferometric signal processing using sinusoidal optical frequency modulation”, Opt. Express 23 (7), 9415 (2015); doi:10.1364/OE.23.009415 |

| [12] | T. Kissinger et al., “Fiber segment interferometry for dynamic strain measurements”, J. Lightwave Technol. 34 (19), 4620 (2016); doi:10.1109/JLT.2016.2530940 |

| [13] | L. Polz et al., “Regenerated fibre Bragg gratings: A critical assessment of more than 20 years of investigations”, Optics & Laser Technology 134, 106650 (2020); doi:10.1016/j.optlastec.2020.106650 |

| [14] | C. Caucheteur et al., “Mode-division and spatial-division optical fiber sensors”, Advances in Optics and Photonics 14 (1), 1 (2022); doi:10.1364/AOP.444261 |

(Suggest additional literature!)

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.