high-power lasers (original) (raw)

Definition: lasers emitting very high optical powers

Category:  laser devices and laser physics

laser devices and laser physics

- light sources

- lasers

* solid-state lasers

* diode-pumped lasers

* lamp-pumped lasers

* distributed feedback lasers

* dye lasers

* gas lasers

* free-electron lasers

* radiation-balanced lasers

* cryogenic lasers

* visible lasers

* eye-safe lasers

* infrared lasers

* ultraviolet lasers

* X-ray lasers

* upconversion lasers

* Raman lasers

* high-power lasers

* high-power fiber lasers and amplifiers

* slab lasers

* thin-disk lasers

* lasers for material processing

* chemical lasers

* multi-line lasers

* narrow-linewidth lasers

* tunable lasers

* pulsed lasers

* ring lasers

* seed lasers

* ultrafast lasers

* industrial lasers

* scientific lasers

* alignment lasers

* medical lasers

* space-qualified lasers

* miniature lasers

* OEM laser modules

* lasers for material processing

* lasers for quantum photonics

* lasers for Raman spectroscopy

* (more topics)

- lasers

Related: high-energy lasersthermal lensingnonlinearitiespower scaling of lasersthin-disk lasersslab lasersrod laserslamp-pumped lasershigh-power fiber lasers and amplifierscryogenic lasersradiation-balanced lasersdirect diode lasers

Page views in 12 months: 2746

DOI: 10.61835/uaf Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

📦 For purchasing high-power lasers, use the RP Photonics Buyer's Guide — an expert-curated directory for finding all relevant suppliers, which also offers advanced purchasing assistance.

Contents

Introduction

Lasers with high output powers are required for a number of laser applications, for example for

- laser material processing (laser welding, cutting, drilling, soldering, marking, hardening and laser surface modification)

- large-scale laser displays (→ RGB sources)

- remote sensing (e.g. with LIDAR)

- medical applications (e.g. surgery)

- military applications (e.g. anti-missile weapons)

- fundamental science (e.g. high intensity physics or particle acceleration)

- laser-induced nuclear fusion (e.g. in the NIF project)

Material processing with high-power lasers is the second largest segment of laser applications in terms of global turnover (after communications).

There is no commonly accepted definition of the attribute “high-power”; in the context of laser material processing, it usually means multiple kilowatts or at least a few hundred watts, whereas for laser displays some tens of watts may already be considered as high power. In some areas, this label is assigned simply for generating a significantly higher output power than other lasers based on the same technology; for example, some “high-powered” laser pointers emit a few hundred milliwatts, whereas ordinary laser pointers are limited to a few milliwatts.

Additional aspects come into play for pulsed lasers. For example, the peak power may be as important as the average output power for a Q-switched laser. Depending on the pulse repetition rate and pulse duration, the peak power may be very high even for a laser with a moderate average output power. Usually, a high average power and not only a high peak power is expected from a high-power laser.

There is the related term high-energy lasers, with emphasis on the pulse energy rather than on the average power.

Technical Challenges

The generation of high optical powers in lasers involves a number of technical challenges:

- One requires one or several powerful pump sources. While lamp pumping was originally the only viable approach for most solid-state lasers, pumping with high-power laser diodes (diode bars or diode stacks) has become widespread. Diode-pumped lasers now offer the highest output powers in continuous-wave operation.

- For very high pulse energies (e.g. tens of joules), lamp pumping is still more practical.

- At least for long-term continuous-wave operation, a high wall-plug efficiency is an important economic factor. Unfortunately, various technical challenges (e.g. thermal effects, see below) tend to make it more difficult at very high power levels to achieve a good efficiency.

- Even in a fairly efficient laser gain medium, a substantial fraction of the pump power is converted into heat, which can have a number of detrimental side effects. In the worst case, thermally induced stress leads to fracture of the laser crystal. High-power solid-state lasers also exhibit strong thermal lensing, making it substantially more difficult to achieve a high beam quality. In lasers with polarized output, depolarization loss often compromises the efficiency. Efficient heat removal and thermal management are therefore important issues, and additional measures (e.g. in the context of resonator design) are often required for coping with various kinds of thermal effects.

- Particularly in Q-switched lasers, very high optical intensities can occur, which may lead to laser-induced damage of optics (such as laser mirrors) e.g. via laser-induced breakdown. Even if the optical intensities remain well below the damage threshold of all optical elements, tiny dust particles can provoke damage phenomena. It can therefore be essential to keep the laser setup very clean, e.g. by operating it in a sealed case which may be opened only in a clean room. In addition, it can be imperative to use precision optics with a high optical damage threshold.

- Various types of nonlinear optical effects can also become relevant, particularly in high-power fiber lasers. Examples are stimulated Raman scattering, Brillouin scattering and four-wave mixing.

- Laser resonators with large effective mode areas tend to be sensitive to misalignment and vibrations of optical components. It can therefore be more challenging to achieve robust maintenance-free operation and a good beam pointing stability.

- Required cooling systems, based on ventilators or water flow, for example, introduce vibrations which may affect laser operation. Also, they may reduce the system reliability, e.g. through water leaks, insufficient water flow and the deposition of dirt in water channels.

Types of High-power Lasers

There are several different types of high-power lasers:

- High-power diode bars and diode stacks have already been mentioned above as possible pump sources for solid-state lasers. They allow the generation of kilowatts of output power, but with a poor beam quality. For some applications, where beam quality is not essential, the direct use of high-power laser diodes (→ direct diode lasers) e.g. for laser welding, soldering and brazing, cladding and heat treatment, is an interesting option, offering a comparatively simple, compact, cost-effective and energy-efficient solution.

- There are various types of lamp-pumped or diode-pumped solid-state bulk lasers. Rod lasers can be optimized for several kilowatts of output power, but diffraction-limited beam quality is possible only up to a few hundred watts (with significant efforts).Slab lasers can be developed for tens of kilowatts or more with relatively high beam quality.Thin-disk lasers easily generate hundreds of watts or even several kilowatts with diffraction-limited beam quality and have the potential to reach that even at power levels well above 10 kW (using multiple laser heads in a laser resonator). Their power efficiency is usually fairly high, well above 50 % optical-to-optical.

- High-power fiber lasers and amplifiers can generate up to a few kilowatts with close to diffraction-limited beams and high power efficiency. With relaxed beam quality requirements, even significantly higher powers are possible. Strictly, such fiber devices are often not lasers, but master oscillator power amplifier (MOPA) configurations.

- Some gas lasers, e.g. CO2 lasers and excimer lasers, are also suitable for hundreds or thousands of watts of output power. They typically operate in different spectral regions than solid-state lasers, e.g. in the mid-infrared or ultraviolet region.

- There are chemical lasers with multi-kilowatt or even megawatt output powers, explored e.g. in the context of anti-missile weapons.

- Some free-electron lasers can generate very high output powers, even in extreme spectral regions, but are large and expensive.

A perhaps not very practical, but theoretically very interesting high-power laser concept is that of the radiation-balanced laser. Here, the heat generation in the gain medium is essentially eliminated by optical refrigeration. The power conversion efficiency, however, is quite low.

An aspect of great importance for further laser development is that of power scaling, based on certain power-scalable laser architectures. Even for not power-scalable laser types, it can be very helpful to understand the scaling properties of various parts or techniques.

Safety Issues

The use of high-power lasers raises important issues for laser safety:

- The output powers are far higher than what any eye can tolerate, so that even tiny parasitic reflections must be safely prevented from reaching an eye. Even the use of strongly absorbing laser safety glasses may not be sufficient, as such glasses may not be able to stand such high optical intensities for more than a brief moment of time.

- The skin and clothes of workers are also at risk in environments where optical powers and intensities are sufficient e.g. for laser cutting of metals.

- High-power laser beams may incinerate materials such as plastics or wood. That happens easily already for laser powers of the order of 1 W. Fire protection is therefore an important issue. Also, the formation of poisonous fumes needs to be avoided, or such fumes have to be efficiently removed.

- There are various types of risks which are not related to the laser beams themselves. In particular, high-power electric power supplies often involve high electric voltages, which can cause electric shocks. Power cables, which can be damaged in a harsh industrial environment, can also create hazards.

An important safety principle in the area of high-power lasers is to enclose the laser setup with a solid housing, and ideally also the whole area where dangerous laser beams can be present. Interlocks can prevent the operation of a laser at times when persons are in a hazardous area.

Frequently Asked Questions

What is considered a high-power laser?

There is no universally accepted definition. The term is context-dependent: in laser material processing, it often means multiple kilowatts, whereas for laser displays tens of watts may already be considered high power.

What are the main applications of high-power lasers?

What are the main challenges when building high-power lasers?

Which types of lasers can deliver high output powers?

Which high-power lasers offer the best beam quality?

What is the difference between a high-power and a high-energy laser?

A high-power laser is characterized by a high average optical power, often in continuous-wave operation. In contrast, the term high-energy laser emphasizes a high pulse energy, which is crucial for many pulsed applications.

Why is safety a critical issue for high-power lasers?

Their beams are extremely hazardous. Even a brief exposure to a stray reflection can cause permanent eye damage. They also pose a significant fire risk and can burn the skin, necessitating strict laser safety measures like protective enclosures.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 108 suppliers for high-power lasers. Among them:

⚙ hardware

Innolume offers high-power broad-area (BA) laser diodes for demanding photonic applications, with output powers of up to 15 W from a single emitter and exceeding 100 W in bar configurations.

All devices are optimized for effective thermal management via p-side down soldering, ensuring low thermal resistance and reliable operation at high current densities.

These laser diodes are customizable in both aperture width (up to 250 µm) and cavity length (up to 5 mm) to meet specific customer requirements. Devices are available in the following configurations:

- TO cans

- C-mounts

- AlN submounts

- bars

- bare dies

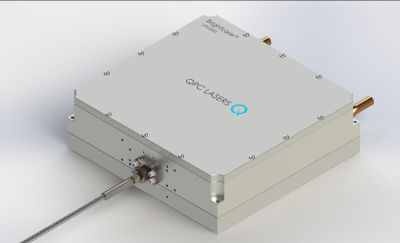

⚙ hardware

QPC Lasers manufactures diode lasers with the highest powers and brightness in the industry at wavelengths ranging from 780 to 2000 nm.

Full vertical integration from epitaxy through packaging allows us to offer standard and custom diode solutions in packages ranging from C-mounts to complete OEM light engines that provide performance without compromise. Features include Brightlock monolithically spectrally stabilized diodes for unmatched linewidth and spectral control.

⚙ hardware

At wavelengths between 3.9 and 9.7 μm, Alpes Lasers offers multiple high power Fabry-Pérot lasers up to 1.5 W. These Quantum Cascade Lasers have a minimum average power of 1 W and more than 9 W of peak power. Available in a collimated HHL package with a dedicated driver, these lasers can be used for free-space optical communications, energy deposition, illumination and IR countermeasures.

⚙ hardware

The ALS-IR and ALS-VIS high-power fiber lasers now feature expanded standard wavelengths, offering greater flexibility for power-demanding applications. These turnkey systems ensure high beam quality, low noise, and robust industrial performance. Fiber technology is versatile, and a number of parameters can be adjusted to fit your need. Don’t hesitate to reach out to us for a discussion if you don’t find what you need in here. Examples are multiple outputs, parallel amplification, upcycling of non-converted IR, and more.

⚙ hardware

Our high-power solid state lasers push the word “high” a bit further. High energy per pulse (1 J), high repetition rate (300 Hz), high average power (300 W) and high peak power (30 kW) together in the big brother of the family. We can manufacture our high energy solid state laser solutions with Nd:YAG or Nd:YLF as active media and use frequency conversion to deliver unprecedented laser properties in IR, green and UV while increasing the most demanding applications’ throughput.

⚙ hardware

CNI high power lasers include both DPSS lasers and diode lasers. They are widely used in medical, scientific research, material processing and industrial applications. Available wavelengths are include 532 nm, 556 nm, 589 nm, 660 nm, 808 nm, 880 nm, 980 nm, 1064 nm, 1319 nm and others. The average output power of 532-nm green lasers can be up to 200 W, and the 1064-nm infrared lasers deliver up to 500 W.

⚙ hardware

The Lumics LuOcean diode lasers are ideal for OEM integrators aiming to develop state-of-the-art end-user laser systems, featuring single emitters with a very long service life and up to four different wavelengths. Users can choose from a wide range of wavelengths, including 670 nm, 760 nm, 785 nm, 808 nm, 890 nm, 915 nm, 940 nm, 975 nm, 1064 nm, 1470 nm, and 1940 nm with custom wavelengths and specifications available upon request. The modules can be configured to match the customers power requirements. Optional enhancements such as temperature, fiber and power monitor sensors and pilot beams further extend the module's capabilities.

⚙ hardware

Bright Solutions has different kinds of high-power lasers:

- the BDL and BFD fiber-coupled diode laser modules with up to 100 W CW output power

- the Vento sub-nanosecond MOPA lasers with pulse durations down to 500 ps, up to 200 kHz, up to 100 W average power at 1064 nm or 50 W at 532 nm, e.g. for LIDAR or PCB microprocessing

- the Aero high energy lasers with up to 200 mJ at 1064 nm, 100 mJ at 532 nm, for application e.g. in atmospheric LIDAR, LIBS or nonlinear spectroscopy

⚙ hardware

GPE series disk laser systems offer 200 mJ pulse energy and 1 kHz repetition rate, also diffraction-limited beam quality, making them ideal for both scientific and industrial applications. These systems can be integrated with Optical Parametric Amplifiers (OPA) or Optical Parametric Chirped Pulse Amplification (OPCPA) to generate picosecond laser pulses with ultra-high peak power. This capability is essential for advanced applications such as:

- Attosecond science

- Terahertz generation

- EUV lithography

- Soft X-ray free-electron lasers

⚙ hardware

The Fireline Laser (FL) is a TEC high power direct semiconductor laser pattern generator providing high reliability with superior beam shaping for high signal to noise industrial applications. With powers up to 12 W in the NIR range, the FL is ideal for high speed applications requiring peak illumination performance such as road and rail inspection. Fully integrated with laser beam shaping to create highly uniform single line and multi-line projections, the FL is a plug and play solution. Features include active diode cooling, DB9 Connector for interfacing and safety protocols such as key switch, mechanical shutter and interlock.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.