fiber cleavers (original) (raw)

Definition: instruments for preparing fiber endfaces with clean optical surfaces

Category:  fiber optics and waveguides

fiber optics and waveguides

- optics

- fiber optics

* fibers

* fiber connectors

* fiber-optic adapters

* fiber couplers

* fiber-optic pump combiners

* fiber bundles

* fiber endface inspection

* cleaving of fibers

* fiber cleavers

* fiber joints

* fiber splices

* fiber Bragg gratings

* fiber cables

* fiber coatings

* fiber strippers

* fiber recoaters

* fiber coils

* fiber collimators

* fiber launch systems

* fiber lenses

* fiber loop mirrors

* fiber patch panels

* fiber shuffles

* fiber-optic attenuators

* fiber-optic plates

* fiber-optic tapers

* (more topics)

- fiber optics

Related: cleaving of fibersfiber jointsfiber optics

Page views in 12 months: 311

DOI: 10.61835/lqm Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

📦 For purchasing fiber cleavers, use the RP Photonics Buyer's Guide — an expert-curated directory for finding all relevant suppliers, which also offers advanced purchasing assistance.

Contents

Principle of Fiber Cleaving

In fiber optics, it is often necessary to prepare clean surfaces for the endfaces of optical fibers. This is often done by cleaving, i.e., by controlled breaking. Instruments used for that purpose are called fiber cleavers.

For general aspects of cleaving, such as basic principles, problematic cases and the inspection of cleaving results, see the article on cleaving of fibers.

Simple Cleaving Blades

The simplest cleaving method uses only a diamond blade, incorporated into a pen-shaped scribe, with which one manually makes a tiny scratch on the fiber, in a direction perpendicular to the fiber axis. (Note that too strong scratching can spoil the results.) One then holds the fiber on one end and gives the other part a kick with a finger, so that the cleave occurs. Alternatively, one may pull the fiber. Such techniques require some practice, and the results are somewhat variable.

Simple and inexpensive mechanical cleavers can be part of fiber termination kits. They produce less consistent results than high-quality precision cleavers, as described below. At least, their use requires more practice, and normally such devices are applicable only to standard silica fibers.

Precision Fiber Cleavers

Cleaving techniques with more controlled conditions allow for more consistent results. For that purpose, there are special apparatuses, called mechanical precision fiber cleavers, which work as follows:

- The fiber is inserted into the cleaver (after stripping its coating) and fixed, typically with a V-groove and two clamps.

- By turning a handle, one then applies a tension, the magnitude of which can often be adjusted (e.g. with a screwdriver). That tension alone is not sufficient to break the fiber.

- With a second handle, one now carefully lets a diamond blade approach the fiber, causing the required scratch. The blade may be made to vibrate with a small electromagnet or piezo.

- Finally, the tension is increased so that the fiber breaks.

With some cleavers, the tension during application of the blade is already high enough for the fiber to break.

There are versions of mechanical semi-automatic fiber cleavers which also allow for angle cleaving (see Figure 1), i.e., for preparing fiber endfaces with some angle against the fiber axis. For that purpose, the fiber is somewhat twisted before it is cleaved. Tentatively, stronger twisting leads to larger cleave angles, but that relation also depends on the tension, and there can be a substantial variation of cleave angles from try to try.

Figure 1: When light comes out of a fiber with angled cleave, it will be somewhat deflected.

The direction for reflected light is also shown; it will not go back to the fiber core.

Some precision fiber cleavers are part of fusion splicing apparatuses, as precision cleaving is a prerequisite for successful splicing.

Frequently Asked Questions

What is a fiber cleaver?

A fiber cleaver is an instrument used in fiber optics to prepare clean endfaces on optical fibers through a process of controlled breaking, known as cleaving.

How does a precision fiber cleaver work?

A precision cleaver clamps the stripped fiber, applies a controlled tension, makes a precise scratch with a diamond blade, and then increases the tension until the fiber breaks cleanly at the scratch.

What is the difference between simple and precision fiber cleavers?

Simple cleavers, like pen-shaped scribes, are manual and produce variable results depending on user skill. Precision cleavers are mechanical devices that provide more control over the process, leading to more consistent, high-quality cleaves.

What is angle cleaving?

Angle cleaving is a technique used to create a fiber endface at a specific angle to the fiber's axis. This is often achieved by twisting the fiber before cleaving and is useful for minimizing back-reflections into the fiber core.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 29 suppliers for fiber cleavers. Among them:

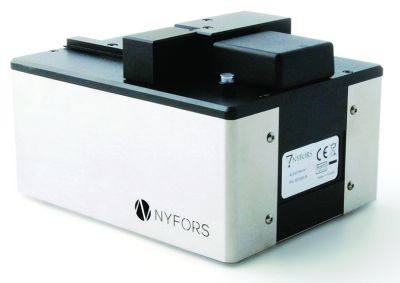

⚙ hardware

The AUTOCLEAVER series is a comprehensive product platform with various models for cleaving standard and large diameter optical fibers, all based on our proven and patented tension and scribe cleaving process. Different models are carefully optimized for precision cleaving of standard, specialty and large diameter fibers with cladding diameters between 80 and 1000 μm. A common feature is the automated cleaving process intended to provide consistent results and high production yield in volume manufacturing environments. Low maintenance requirements ensure trouble-free operation during long periods of operation.

We have an open interface for integration into automated production systems. Fiber holder solutions are available for use with fusion splicers from Fujikura, Furukawa/FITEL and Vytran. Dual fiber holder positions for comfortable use with FSM-100 fusion splicers.

See our cleaver comparison sheet.

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.