fiber cables (original) (raw)

Definition: cables containing one or several optical fibers

Category:  fiber optics and waveguides

fiber optics and waveguides

- optics

- fiber optics

* fibers

* fiber connectors

* fiber-optic adapters

* fiber couplers

* fiber-optic pump combiners

* fiber bundles

* fiber endface inspection

* cleaving of fibers

* fiber cleavers

* fiber joints

* fiber splices

* fiber Bragg gratings

* fiber cables

* fiber patch cables

* fiber coatings

* fiber strippers

* fiber recoaters

* fiber coils

* fiber collimators

* fiber launch systems

* fiber lenses

* fiber loop mirrors

* fiber patch panels

* fiber shuffles

* fiber-optic attenuators

* fiber-optic plates

* fiber-optic tapers

* (more topics)

- fiber optics

Related: fiber patch cablesfibersfiber bundlesfiber opticsfiber connectorsoptical fiber communications

Page views in 12 months: 348

DOI: 10.61835/eao Cite the article: BibTex BibLaTex plain textHTML Link to this page! LinkedIn

Content quality and neutrality are maintained according to our editorial policy.

📦 For purchasing fiber cables, use the RP Photonics Buyer's Guide — an expert-curated directory for finding all relevant suppliers, which also offers advanced purchasing assistance.

Contents

Key questions:

- What is an optical fiber cable and what are its main components?

- What are the different types of optical fiber cables and their uses?

- What kinds of protective layers can be used?

- What are the different NEC classifications for optical fiber cables?

- What standardized characteristics have been developed for telecom fiber cables?

- What are the common applications of optical fiber cables in communication?

- How are fiber cables used in laboratory and industrial setups?

What is a Fiber Cable?

An optical fiber cable (or fiber-optic cable) is a flexible cable which contains one or multiple optical fibers. These cables can range from carrying a single fiber to accommodating dozens or even hundreds, depending on the application. Unlike bare fibers, fiber cables incorporate multiple layers of protection which provide robustness against mechanical stress, prevent excessive bending, and offer significant resistance to environmental hazards such as moisture.

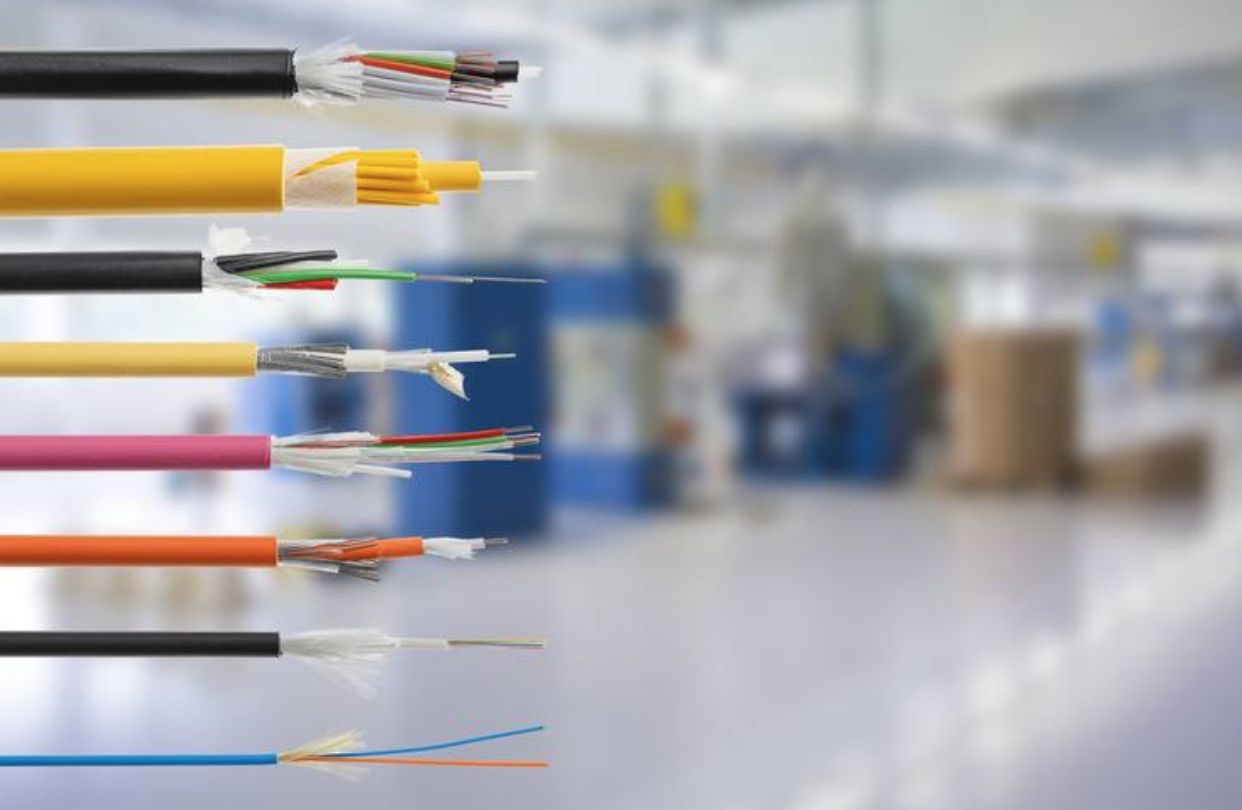

Figure 1: Photograph of fiber-coupled diode lasers, having different kinds of fiber-optic cables. The image was kindly provided by Coherent.

Mechanical Protection and Improved Visibility

A bare glass fiber can already be somewhat protected by a thin surrounding polymer coating. Significantly better protection is achieved with a tight buffered fiber, featuring a thick polymer buffer (typically with 900 μm diameter) closely surrounding the fiber. This is already sufficient in some situations. Still, this is not called a fiber cable.

However, one or more such buffered fibers can be further integrated into fiber cables, with additional protective material, e.g. with a yellow (highly visible) thick polymer jacket. Fiber cables offer substantially enhanced resilience for field use. Examples of their application areas are telecom infrastructure, data centers, industrial sites, and optical sensors. For example, such cables are common for transporting light from a source to an application, or some light signals to diagnostic instruments like optical spectrum analyzers.

Even for a fiber cable in a setup on a laboratory table, which is not exposed to harsh conditions, the additional protection may be useful — for example, against some instrument inadvertently placed on an overlooked fiber. Note that besides mechanical protection, improved visibility of a cable due to its larger diameter and color helps already to avoid damage.

Protection for the enclosed fibers may be provided by various kinds of elements:

- buffer tubes (one or several) for mechanical protection and keeping water outside

- outer jackets/sheaths, typically made of polymers and sometimes containing metallic elements

- strength members for providing tensile strength

- water-blocking gels, tapes or powders inside a tube

- ripcords for easy jacket removal

The detailed construction of a fiber cable can be relatively sophisticated, optimized for an appropriate trade-off between strength, flexibility, diameter, weight, fire resistance, installation ease, cost and other possibly relevant properties. For example, the mechanical details can have an influence on polarization mode dispersion.

Environmental Influences

For indoor cables, fire safety is an important aspect, whereas for outdoor cables, moisture resistance and temperature tolerance are factors of high interest.

Special aerial/self-supporting cables can be exposed to wind in free air (hanging on poles). They must have a particularly high pulling strength and overall robustness, using some steel or aramid yarn. In addition to thermal durability, UV resistance is important in case of sunlight exposure; note that irradiation with ultraviolet light can make polymers rather fragile.

Outdoor cables could easily tolerate indoor conditions, but are often not allowed for indoor use (or only with certain restrictions) due to issues with fire protection. Indoor cables can also have safety advantages from low smoke production and low toxicity during combustion.

Identifying Fibers and Cables By Coding

Color coding of optical fiber cables and their components provides a quick visual indication of fiber type, installation environment, and sometimes national or regional compliance.

In many regions, cable jacket colors indicate the optical fiber type. For example, in North America (per TIA/EIA and ANSI standards) for non-military applications:

- yellow: single-mode fiber (OS1/OS2)

- orange: Multimode OM1 / OM2 (62.5/125 µm or 50/125 µm)

- aqua: multimode OM3 / OM4 (50/125 µm, laser-optimized)

- lime green: multimode OM5 (wideband 50/125 µm)

- blue: polarization-maintaining single-mode fiber (indoor)

- black: outdoor cables (fiber type identified by printed legend)

These color conventions are not universal, but they are widely used in commercial and data-center environments. There are also standardized connector color codes (e.g., blue for single-mode, beige for OM1/OM2 multimode, aqua for OM3/OM4).

Outside North America, fiber and cable identification often follows IEC and DIN VDE conventions rather than the TIA/EIA color codes.

In Europe, fiber-optic cables are typically marked according to:

- IEC 60794 (optical fiber cable families and mechanical characteristics)

- DIN VDE 0888 in Germany, which defines a letter-based designation for the cable's construction and intended environment rather than jacket color.

For example, a designation such as A-DQ(ZN)B2Y indicates:

- A: outdoor use

- D: dielectric (non-metallic) cable

- Q(ZN): gel-filled loose tubes with a central dielectric strength member

- B2Y: polyethylene (PE) outer sheath, UV-resistant

Thus, in Europe, printed markings and coded designations usually provide more detailed identification than jacket color alone.

Fire-performance classifications for building installations are also harmonized under EN 50575 (CPR), using ratings such as Eca, Dca, Cca, or B2ca instead of color distinctions.

When a cable contains multiple fibers, individual fibers are color-coded for identification during splicing and termination. The most widely used TIA/EIA 598 color sequence is: blue — orange — green — brown — slate (gray) — white — red — black — yellow — violet — rose (pink) — aqua.

For cables with more than 12 fibers, this sequence repeats, with an additional color stripe or ring that changes every 12 fibers.

In European installations, IEC and DIN VDE use equivalent color orders, so technicians can usually recognize and cross-reference fibers between systems.

Applications of Fiber Cables

Fiber cables are useful for a multitude of technologies and industries. Their physical structure, transmission properties, and immunity to interference make them uniquely versatile in communications, sensing, scientific research, industrial automation, and healthcare. The following subsections give some examples. Note that different applications may require cables with very different specifications.

Optical Fiber Communications

Optical fiber cables are foundational to optical fiber communications. Large and strong cables are used for onshore and submarine data transmission, often bridging distances of thousands of kilometers (using fiber amplifiers) while providing huge data capacities. Smaller fiber patch cables can be used e.g. to connect the components of fiber-optic data links within buildings.

The key advantages of fiber-optic cables over electrical (copper) data cables are the enormous transmission bandwidth and the low losses (particularly in the 1.5-μm wavelength region), but one may also profit from the immunity against electromagnetic interference and from the possibility to have fully insulating cables.

Nowadays, many fiber cables for data transmission have been laid down which are not or not yet used (“dark fibers”). This is partly because burying a fiber is much cheaper when a channel in the ground is already opened e.g. for laying electrical cables. One may prefer the risk of never used fiber cables over the other risk that additional groundwork will be required later on.

Fiber-optic Sensors

Various types of fiber-optic sensors perform sensing, e.g. of temperature and/or strain, in a long fiber cable. This can be distributed sensing or sensing only at certain locations. Such sensor cables can be embedded in buildings for monitoring structural integrity, for example.

See the article on fiber-optic sensors.

Fiber cables can also be used for transporting optical signals created by other (non-fiber) sensors.

Fiber Cables in Laboratories

In laboratories, fiber cables are often convenient for transporting light:

- Some diode-pumped lasers have the pump laser diodes spatially separated from a laser head, where the light is transported through a laser delivery cable. That way, one may conveniently exchange the pump source without affecting the actual laser, remove possibly disturbing influences from a sensitive laser, and keep the actual laser more compact.

- Fiber patch cables are often used for connecting different instruments. For example, light from a scientific setup may be led to an optical spectrum analyzer or to other types of diagnostic instruments. Also, patch cables can transmit analog or digital data between devices.

Industrial Manufacturing

In industrial setups, fiber cables are often vital for transporting light from a source to an application. For example, in a car factory, one can transport light from a stationary high-power fiber laser to a laser welding robot. In such cases, very high power levels (many kilowatts) can be involved.

Other uses of fiber cables in industry settings are sensing and optical fiber communications.

Medical Applications

There are diverse applications of fiber cables in the medical area; some examples:

- Fiber cables can transmit light for endoscopic surgery.

- They can also serve illumination and imaging purposes, e.g. through endoscopes.

- Light for photodynamic therapy may also be transported through a fiber cable.

- Some medical sensors for monitoring temperature, pressure or blood flow are fiber-based.

- Various other medical devices, e.g. involving optical coherence tomography (OCT), also use fiber cables.

Types of Fiber Cables

A wide variety of constructions is used for fiber cables, depending on the requirements of the application area:

Cables Containing Tight Buffered Cables

One or multiple tight buffered fibers (sometimes hundreds of them) can be housed in a larger cable structure, which often includes

- aramid yarn (e.g., Kevlar) for tensile strength,

- ripcords for easier sheath removal,

- outer jackets (commonly PVC for indoor use),

- and sometimes a central strength member for improved mechanical integrity.

Distribution cables (containing individually color-coded fibers) are typical in horizontal and backbone wiring within facilities.

Breakout (or fanout) cables contain individually jacketed fibers, each with its own strength elements, suitable for direct termination. These are robust but bulkier and more costly.

Simplex and Duplex Cables

While a simplex cable contains a single fiber, a duplex fiber has two fibers with a joined sheath — for example, for transmitting data signals in two directions. They are common in patch cords between active equipment.

Ribbon Cables

Ribbon cables hold multiple fibers (typically 12, but up to 24 or more) aligned in a flat, parallel array.

Multiple ribbons can be stacked to achieve very high packing densities in a cylindrical cable.

Ribbon cables facilitate high fiber counts and enable mass fusion splicing for rapid installation in large-scale telecom networks.

Fiber Bundle Cables

Fiber bundle cables group large numbers of optical fibers, called fiber bundles. They can have either ordered (coherent) or unordered (incoherent) arrangements. They are used in illumination, imaging, and in some optical sensing applications. Unlike telecom cables, fiber bundle cables often do not transmit data signals but rather only transport light for lighting, endoscopy, or spectroscopy.

See also the article on fiber bundles.

Loose-tube Cables

Loose-tube cables enclose one or more fibers within a large-diameter tube, with the fibers “floating” amid air or a moisture-blocking gel. There can also be multiple loose tubes in one cable. These may be color-coded for easily distinguishing them.

Additional layers may include water-blocking wraps to prevent ingress, metallic armor or polyethylene outer jackets for robust outdoor protection.

The loose-tube design allows fibers to move freely, minimizing strain during installation and thermal cycling — which is essential in environments with large temperature fluctuations or risk of ground movement. The construction ensures minimal mechanical stress transfer to the fibers, which also reduces polarization mode dispersion. Loose-tube cables can tolerate some amount of stretching (also thermal expansion and contraction), which would usually break glass fibers, but the loose tubes can contain some excess length of fiber.

The protection in loose-tube cables is often sufficient for outdoor use. However, loose-tube cables are less convenient concerning connectorization (because of the not well-defined positions of the fibers) and sometimes not suitable for installation in vertical ducts.

Armored and Submarine Cables

Armored fiber-optic cables contain an extra outer layer of steel or other tough metals for resistance to rodents, crushing, and other severe mechanical impacts. They are suitable for direct burial in harsh environments or installations where physical hazards are likely.

Submarine cables are well armored and specially equipped for use in lakes, rivers, and oceans. They must be reliably water-proof and protected against severe mechanical stress e.g. from boat anchors or fishing equipment. Some also contain electrical conductors for powering signal repeaters.

High-power Fiber Cables

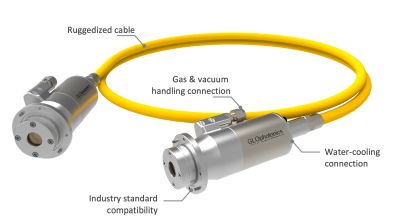

In industrial laser material processing like laser cutting or laser welding, the output of high-power lasers often needs to be transported, e.g. from the stationary laser source to a rapidly moving laser processing head. The relevant optical power can easily be multiple kilowatts, sometimes even beyond 10 kW. Industrial applications with such power levels introduce additional requirements:

- One uses multimode fibers with substantial fiber core areas — although not more than necessary, as that could impact the usable beam quality. Partly, one uses metal-coated fibers with improved thermal handling. The fiber endfaces also require special attention, e.g. with optimized preparation techniques and fiber connectors.

- Minimum transmission losses are required — not only to avoid losing power at the workpiece, but also because any dissipated power can lead to problematic heating. In some cases, water cooling is required.

- Particularly high mechanical robustness is required for harsh production environments. Not only does one need to protect the fiber as such, but also minimize the risk that hazardous high-power laser radiation can exit a broken cable.

- Particularly for laser safety reasons, high-power laser cables may incorporate dedicated fiber-based sensors to monitor real-time output. For example, one technique uses an in-line fiber-tapping method, sampling a small fraction of cladding light in double-clad output fibers. This allows rapid detection of any problem, and automatically turning off the laser source before greater damage arises. Distributed temperature sensing is another possibility.

- Materials and design may also need to protect against moisture, solvents, and process gases in industrial settings.

- Fiber cables may contain additional data fibers, e.g. for receiving process data and images from a laser processing head. However, it is more common to use separate optical or electrical cables for such purposes.

Specialty Fiber Cables

Some fiber cables contain specialty fibers. For example, there are hollow-core photonic crystal fibers for the delivery of intense ultrashort light pulses.

Fiber Connectors

The terminations (ends) of fiber cables are usually equipped with fiber-optic connectors; they may either be sold as pre-terminated assemblies or equipped with connectors after installation. Fiber connectors allow relatively simple plugging, as is possible with electrical cables; this works also for multi-fiber cables with high fiber count. However, fiber-optic connections are usually more sensitive than electrical connections, and more sophisticated procedures and equipment are needed to prepare or clean them.

Various types of fiber-optic patch cables (patch cords) are available, which are terminated with standardized fiber connectors.

Long-distance cables are made by connecting multiple cables, each one being a few kilometers long. Stable connections can be made with splicing, in particular with fusion splicing.

NEC Classification of Optical Fiber Cables

There exist many variations of fiber cables, to which some classifications are applied. A common classification according to the National Electrical Code (NEC) in the United States is as follows:

- OFC cables are conductive (C) fiber cables, i.e., cables containing metals in strengthening structures (which are not used for electrical connections). In contrast, OFN cables are non-conductive and therefore fully insulating.

- Riser cables, marked with an additional “R” (e.g., OFCR or OFNR), are used for connections between different levels of a building (vertical shafts). They are optimized such that they do not support the spread of fire between different floors.

- Plenum cables, marked with an additional “P” (e.g., OFCP or OFNP), are used in plenum or air-handling spaces — for example, for cables running along ceilings or ventilation ducks. When exposed to fire, they should not produce too much smoke and should be flame-retardant.

- General purpose cables are marked with a “G”, e.g. OFCG or OFNG.

The above-mentioned codes do not specify optical properties of the contained fibers; these can be single-mode or multimode fibers, for example, of any type.

Other Elements of Fiber Cable Specifications

Various elements are often encountered in the nomenclature and specifications of fiber cables or the fibers therein:

- For telecom fibers, ITU has developed some standardized characteristics like “G.651.1”; their mentioning implies that such specifications should be fulfilled.

- Fiber Distributed Data Interface (FDDI) is a standard concerning LAN fiber cables, which, however, with its quite limited transmission speed of 100 Mbit/s has become obsolete due to the improved availability of advanced copper cables.

- There can be additional classifications like OM1, OM2, OM3, OM4 and OM5 for graded-index fibers, which concern the residual level of intermodal dispersion. That limits the transmission bandwidth (or the bandwidth–distance product) of the cable. High performance is achieved e.g. with OM4 50/125-μm laser-optimized fibers, having a very precisely controlled refractive index profile.

- Sometimes, the maximum achievable bandwidth–distance product is specified (in units of MHz·km).

- Specs like “50/125 microns” indicate the core and cladding diameter. Large values of the core diameter — tens of microns — generally indicate multimode fibers.

- The propagation losses are typically specified in units of dB/km (decibels per kilometer). Those apply without significant bending of the cable, so that only some level of microbend losses occurs, apart from absorption and scattering losses.

Fiber Cable Management

Various devices and accessories for fiber cable management are needed for managing telecom fiber cables, particularly where there are many of those. Some examples:

- Fiber patch panels can contain many adapters for fiber connectors. They may be used, for example, where fiber cables come into a building, and their signals need to be distributed.

- Fiber shuffles can provide fixed or even reconfigurable routing of signals between many fibers.

- Various types of accessories allow one to safely and orderly fix many fibers, or to protect sensitive things like fiber splices.

- Labeling solutions help one to keep track of many fibers.

Frequently Asked Questions

What is an optical fiber cable?

An optical fiber cable is a flexible assembly containing one or more optical fibers. It incorporates multiple protective layers to provide robustness against mechanical stress, excessive bending, and environmental hazards like moisture.

What is the purpose of the different layers in a fiber cable?

The layers in a fiber cable, such as buffers, jackets, strength members, and water-blocking materials, provide mechanical strength, prevent damage from bending, and offer resistance to environmental factors like moisture and temperature changes.

How can different fiber types be identified by the cable's color?

Cable jackets are often color-coded according to standards. For example, yellow jackets typically signify single-mode fiber, while orange, aqua, or lime green indicate various types of multimode fibers.

What is the difference between loose-tube and tight-buffered cables?

In tight-buffered cables, a polymer buffer is in close contact with the fiber. In loose-tube cables, fibers are placed within a larger tube, which isolates them from external mechanical forces and is ideal for outdoor environments with temperature fluctuations.

What are the main applications of fiber cables in communications?

In optical fiber communications, robust fiber cables are used for long-distance onshore and submarine data transmission. Smaller fiber patch cables are used to connect equipment within buildings and data centers.

Why are special cables needed for high-power laser applications?

High-power laser cables must handle many kilowatts of optical power. They use fibers with large cores, have minimal transmission losses to prevent heating, require high mechanical robustness, and often include safety sensors to detect cable damage.

What do NEC classifications like OFNR or OFNP mean?

These are National Electrical Code (NEC) fire safety ratings. 'R' for Riser (e.g., OFNR) indicates a cable for vertical runs between floors that prevents fire spread. 'P' for Plenum (e.g., OFNP) is for air-handling spaces and signifies low-smoke and flame-retardant properties.

Suppliers

Sponsored content: The RP Photonics Buyer's Guide contains 106 suppliers for fiber cables. Among them:

⚙ hardware

TOPTICA Photonics AG offers a wide range of optical fibers ideally suited for use with TOPTICAs lasers and FiberDock. These economically priced fibers cover a wide range of wavelengths. TOPTICA recommends to always purchase a fiber along with a laser and fiber coupler, as this ensures maximum fiber coupling efficiency. Also specialty fibers for power monitoring, beam splitting or combining are available with various ratios and also polarization maintaining.

⚙ hardware

We offer a wide selection of FlexiRay® fiber optic cables for the Broad Mid-Infrared Range (3–17 μm) for spectroscopy applications, based on:

Polycrystalline IR (PIR) fibers: PIR cables

Chalcogenide IR fibers: CIR cables

Hollow Glass IR (HGW) fibers: HGW cables

Indium and Zirconium Fluoride Glass fibers: Fluoride cables

These cables are used in various applications such as mid-IR light delivery, spectroscopy, remote temperature sensing, illumination, radiation detection, and process spectroscopy. A wide range of fiber diameters, connectors, and protective jackets is available to meet your specific needs. We also offer Silica Fiber Cables for UV-Vis and Vis-NIR spectral ranges.

art photonics provides a variety of step-index and graded-index, multimode and singlemode silica fiber optic cables for high-performance light transmission.

⚙ hardware

Fibercore brings over 25 years of cable design knowledge and manufacturing expertise to create fiber optic cable designs that are customized to the rigors of specific environments. Fibercore specializes in the harshest of environments, ranging from cryogenic applications to the some of the hottest enhanced oil recovery wells.

⚙ hardware

The process begins with a fiber Bragg grating or FBG array made by Technica. We then package the fiber(s) into specialized cables such as Armor (T110), GFRP (T130), Steel (T140), PEEK/TEFLON (T150), Gold (T160). We also package multiple FBG arrays within the same cable in length ranges far beyond standard available technologies.

⚙ hardware

GLO hollow-core fiber technology for the ultra-fast laser (femtosecond, picosecond and nanosecond) and high power laser. The beam delivery products cover a large parameter space in laser average power, pulse energy and wavelength (from UV to MIR). Beam delivery product family brings the exceptional hollow-core fiber technology performance in laser energy and power handling and in dispersion management to the widest range of applications and requirements.

Bibliography

(Suggest additional literature!)

Questions and Comments from Users

Here you can submit questions and comments. As far as they get accepted by the author, they will appear above this paragraph together with the author’s answer. The author will decide on acceptance based on certain criteria. Essentially, the issue must be of sufficiently broad interest.

Please do not enter personal data here. (See also our privacy declaration.) If you wish to receive personal feedback or consultancy from the author, please contact him, e.g. via e-mail.

By submitting the information, you give your consent to the potential publication of your inputs on our website according to our rules. (If you later retract your consent, we will delete those inputs.) As your inputs are first reviewed by the author, they may be published with some delay.